Flat flexible cable with good conductivity

A conductive performance, flat shape technology, applied in the field of flat flexible cables, can solve the problems of long cable production cycle, shortened production cycle, poor flexibility, etc., and achieve the effect of shortening the production cycle, improving the homogenization effect, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

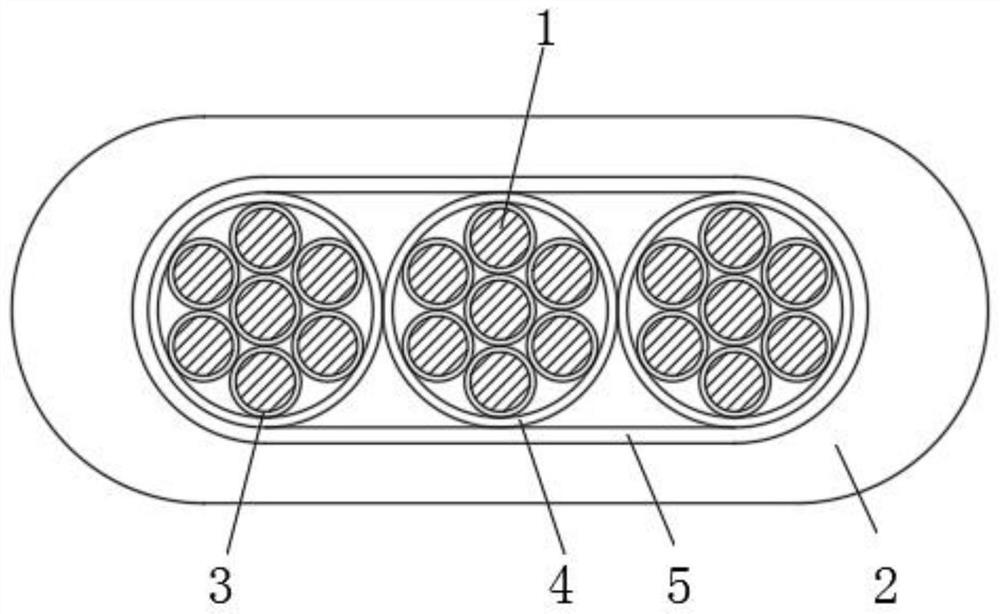

[0036] Such as Figure 1-5 As shown, a flat flexible cable with good electrical conductivity includes a nitrile polyvinyl chloride sheath layer 2, and an aluminum-plastic composite layer 5 is arranged on the inside of the nitrile polyvinyl chloride sheath layer 2, and the aluminum-plastic composite layer 5 Three shielding layers 4 are arranged inside, and seven conductors are arranged inside each of the three shielding layers 4 , and the conductors include the wire 1 and the insulating layer 3 wrapped outside the wire 1 .

[0037] Two adjacent shielding layers 4 are in close contact.

[0038] The production method of this shielding layer 4 specifically comprises the following steps:

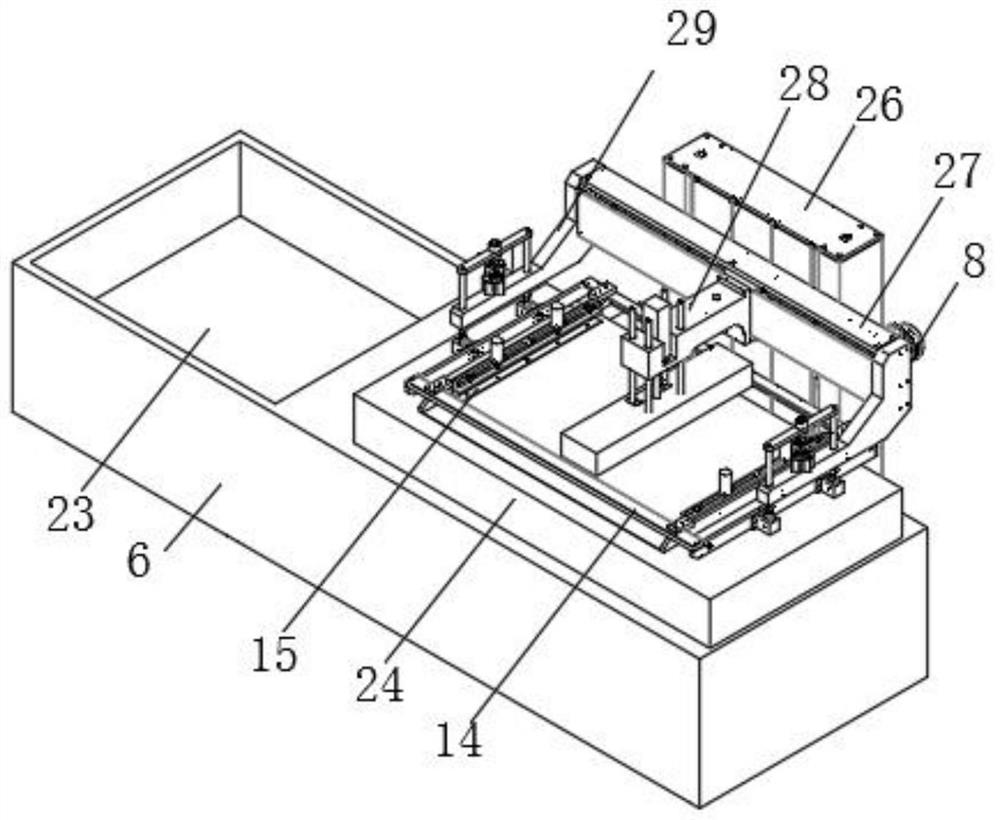

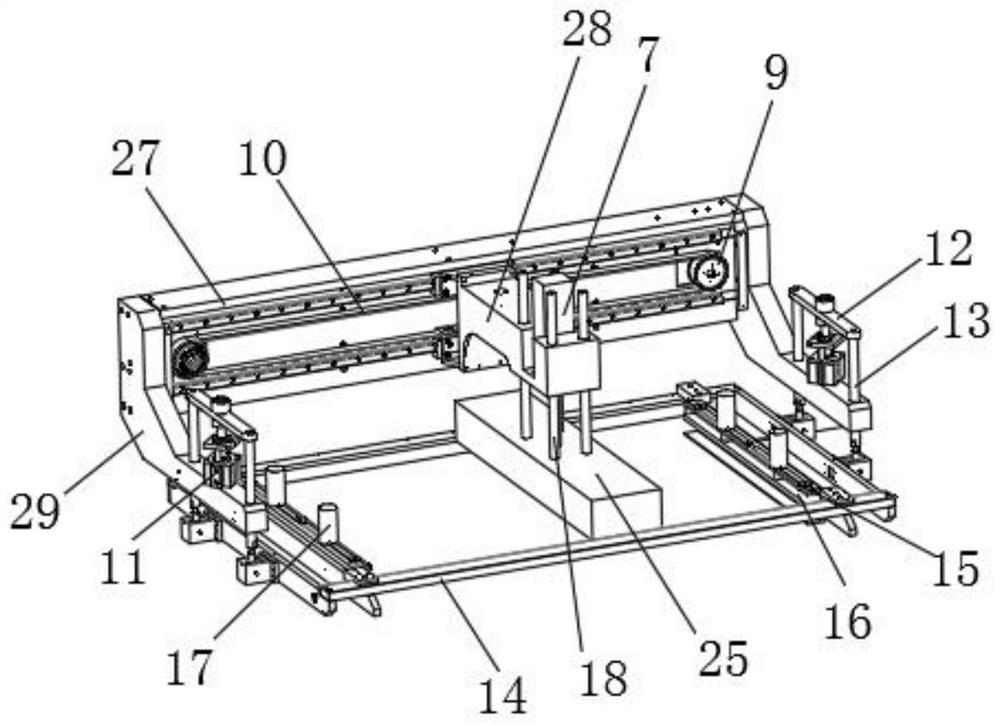

[0039] Step 1. Place the two ends of the aluminum foil on the inside of the two channel steel pallets 15 in the shielding layer processing device, and make the ends of the aluminum foil under the corresponding splint 16, start two third cylinders 17, and the third cylinder 17 The output rod of ...

Embodiment 2

[0048] Such as Figure 1-5 As shown, the production method of the shielding layer 4 specifically includes the following steps:

[0049] Step 1, with embodiment 1;

[0050] Step 2. When the aluminum foil is covered with dents, the mobile trolley 30 drives the mobile support 26 to move, the mobile support 26 drives the lifting horizontal plate 27 to move, and the lifting horizontal plate 27 drives the installation frame plate 14 to move to the tin liquid through the fixed arm 29 Above the tank 23, make the aluminum foil above the tin liquid tank 23, start the second motor 21, the output shaft of the second motor 21 rotates and drives the screw 22 to rotate, the screw 22 drives the lifting seat 19 to descend, and the lifting seat 19 passes through the connecting horizontal plate 20 drives the lifting horizontal plate 27 to descend, and drives the installation frame plate 14 to descend, and drives the aluminum foil to descend, so that the aluminum foil is immersed in the tin liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com