Defective structure-containing high-entropy alloy strength prediction method

A high-entropy alloy strength prediction technology, applied in prediction, instrumentation, data processing applications, etc., can solve the problems that the theoretical model of high-entropy alloy microscopic defect strength has not been established, and the crystal plasticity theory has not been used in high-entropy alloys, etc., to achieve The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

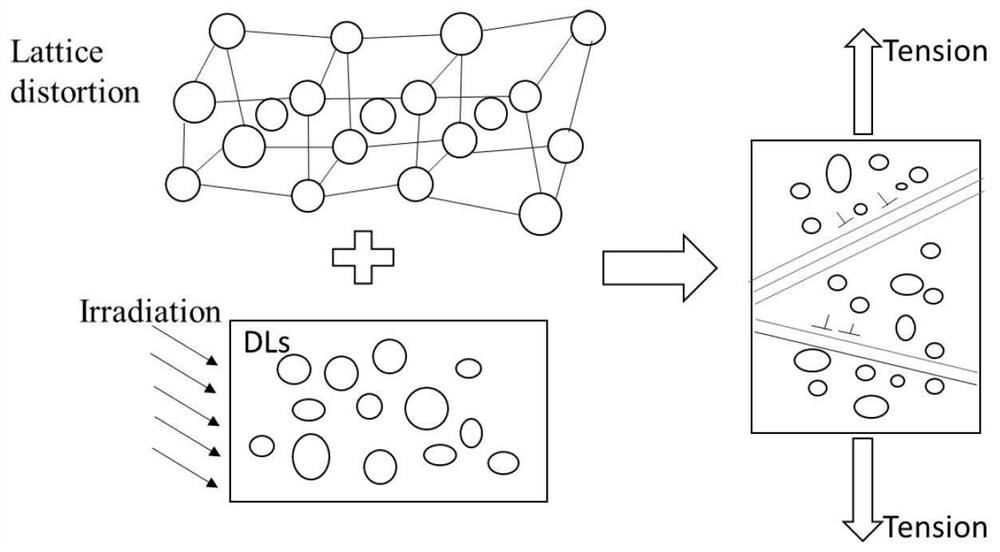

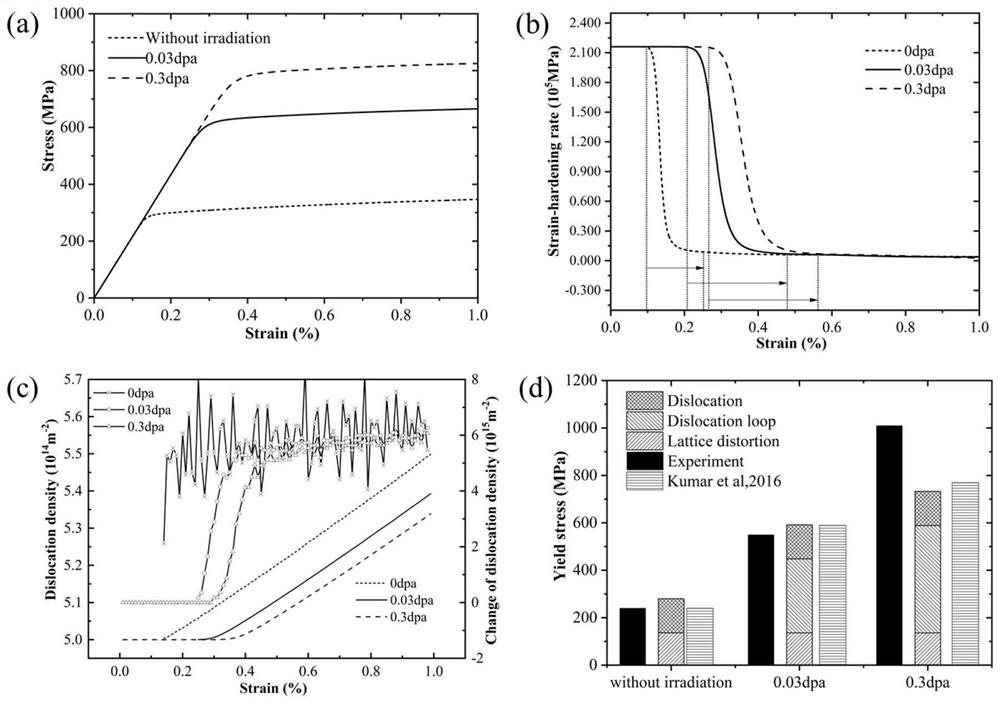

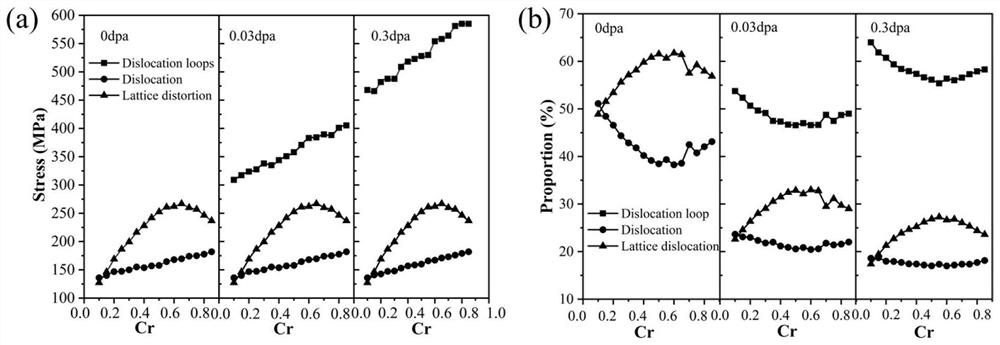

[0054] The following is attached figure 1 A schematic diagram and specific examples of the model of a high-entropy alloy containing dislocation loop defects considering the three effects of dislocation, dislocation loop and lattice distortion are provided, and the technical solution is further elaborated. The present invention is not limited to the following examples. All design ideas utilizing the present invention fall within the scope of protection of the present invention.

[0055] Dislocations are mainly due to the processing and preparation of materials and service, and are used as a characterization of plastic deformation of materials; considering the main defect dislocation loops generated in FeNiMnCr high-entropy alloys during service, they are the main source of material hardening; lattice distortion is the main source of high-entropy Alloys have a strengthening effect on the mechanical properties of materials due to the inherent characteristics produced by the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com