Prediction method for wide-temperature-range creep strength of nickel-based superalloy

A nickel-based superalloy, creep strength technology, used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

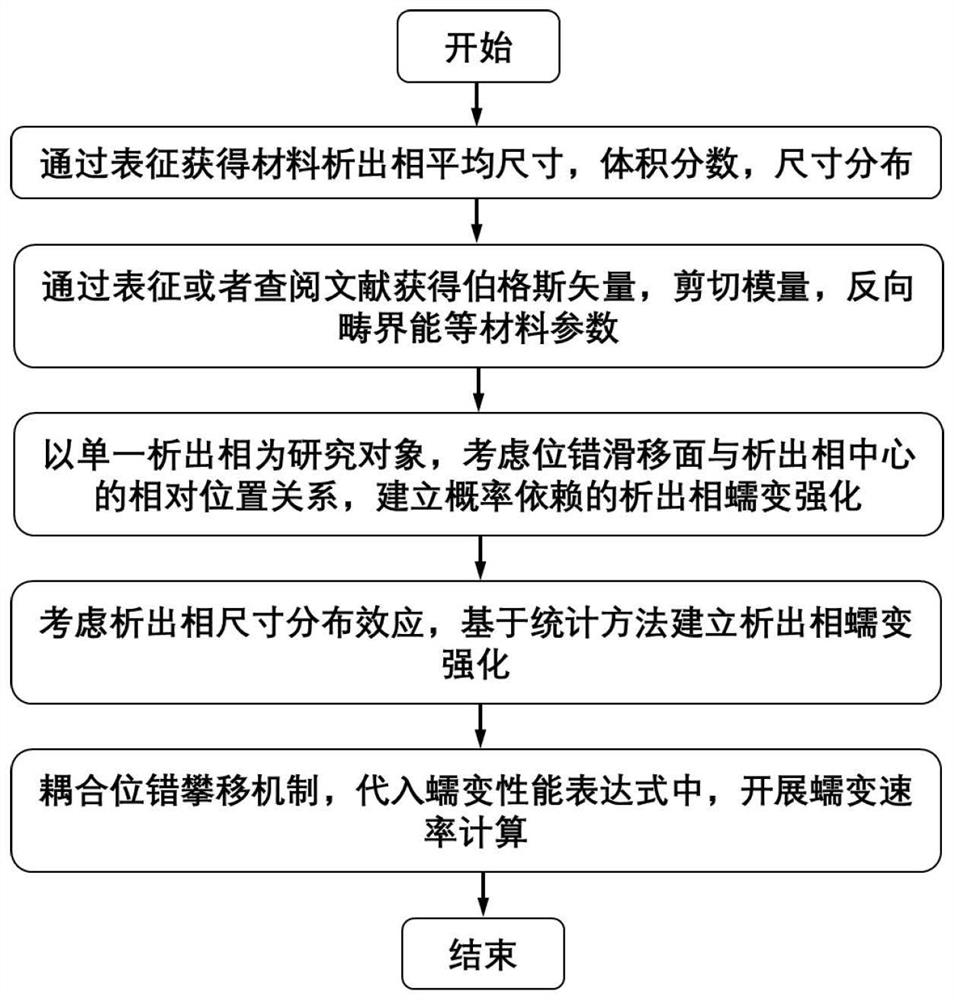

Method used

Image

Examples

example

[0046] Example: Nickel-based MAR-M247 superalloy creep rate prediction under a wide range of stress and temperature loads.

[0047] Specific steps: First, the average size of the precipitates in the nickel-based superalloy is 500 nm and the volume fraction is 60% through experimental characterization. The precipitate size distribution map was then obtained by characterization and the standard deviation was obtained by fitting to a log-normal distribution.

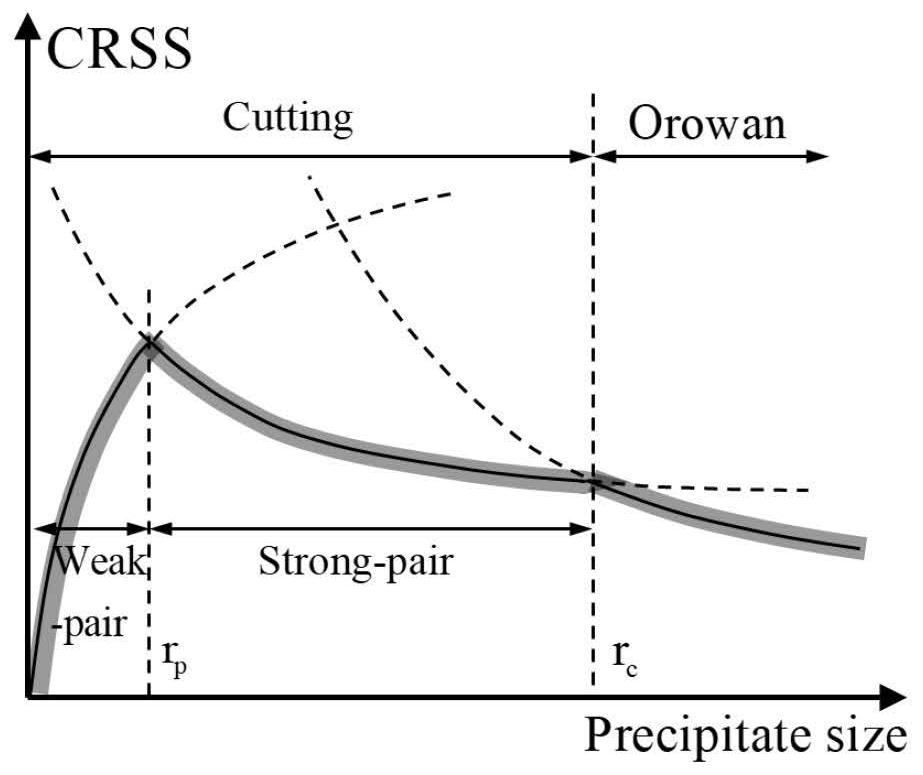

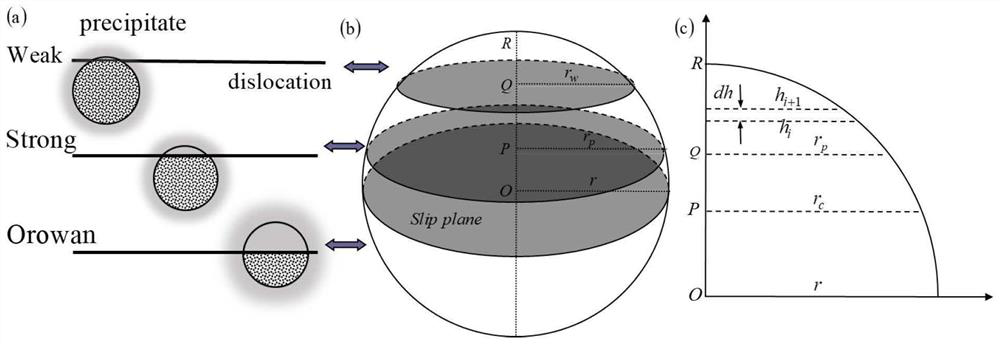

[0048] Then, considering the mutual positional relationship between the dislocation slip plane and the center of the precipitation phase, the creep strength of the precipitation phase with a single average size is obtained ( image 3 ).

[0049] Considering the effect of the size distribution of the precipitates, the creep strength of the precipitates ( Figure 4 ). Here, the creep strength calculated by the classical creep strength prediction method is 293 MPa, while the creep strength predicted by the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| creep strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com