Four-channel micro valve based on dielectric wetting control

A dielectric wetting and four-channel technology, applied in the field of microfluidics, can solve the problems of single control and poor flexibility, and achieve the effects of improving service life, simple design, and preventing damage to components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

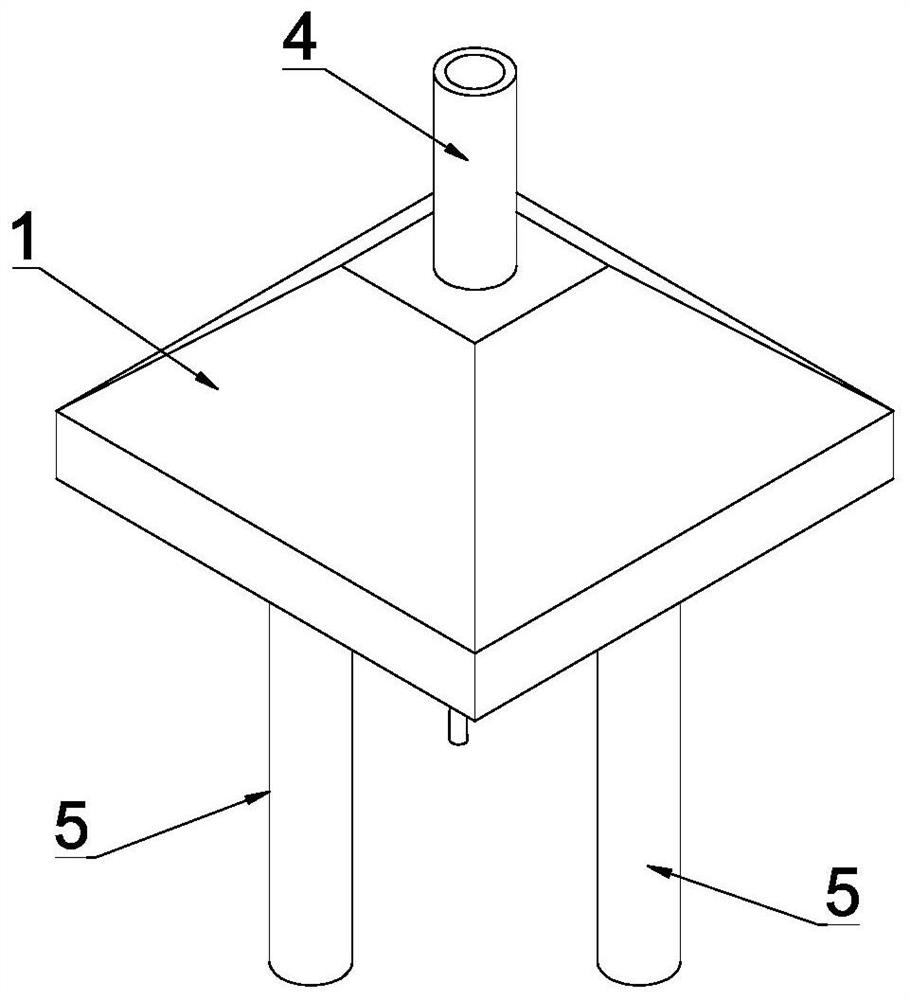

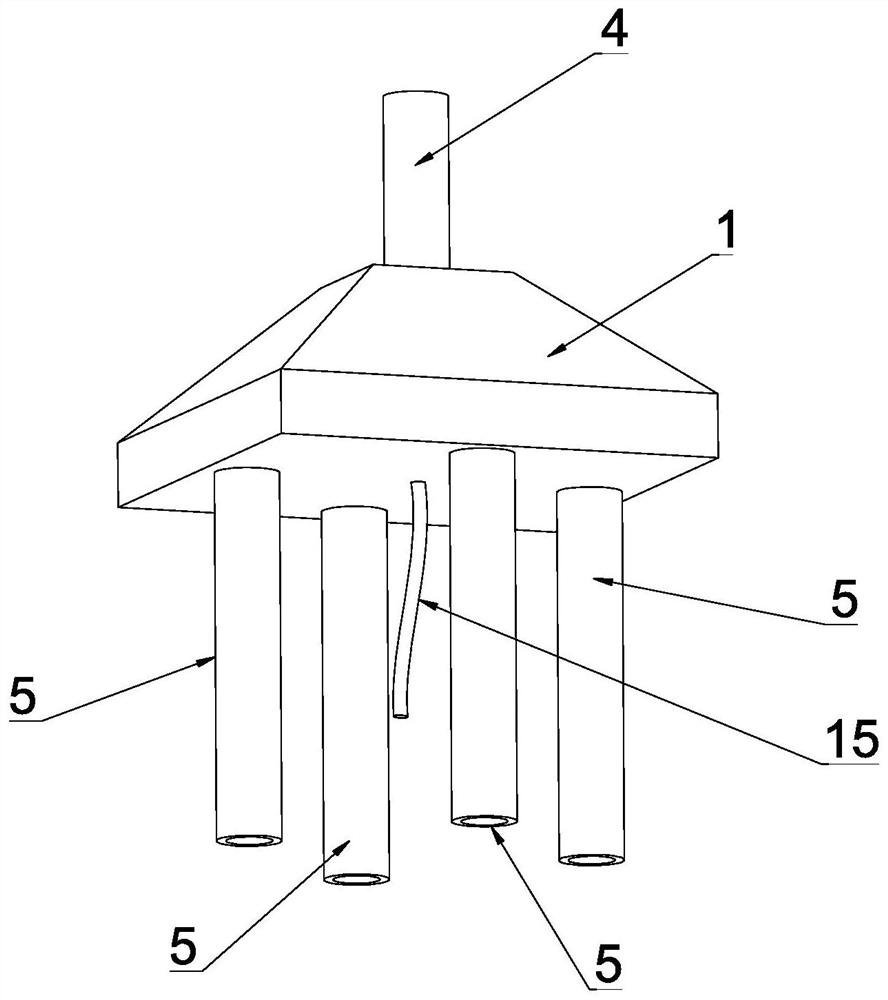

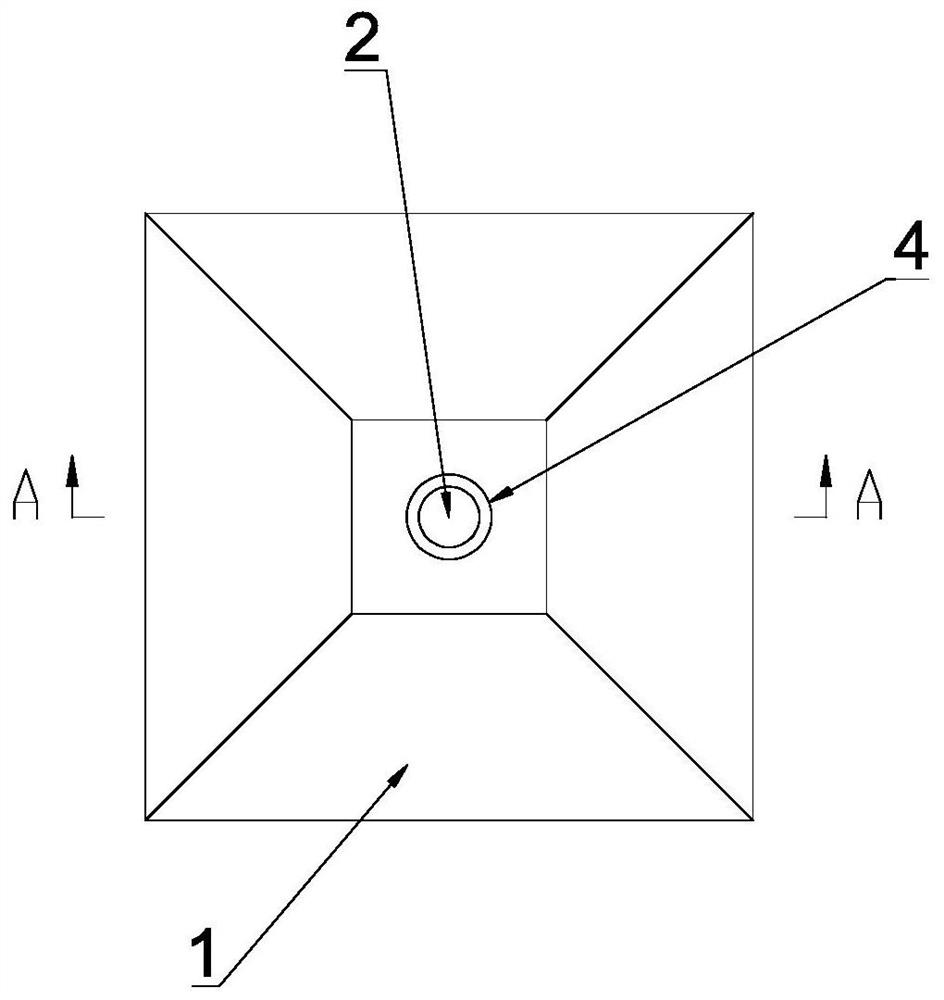

[0040] see Figure 1-Figure 5 , this embodiment discloses a four-channel microvalve based on dielectric wetting control, including a valve body 1, a liquid inlet 2 arranged at the upper end of the valve body 1, and four outlets arranged at the lower end of the valve body 1. The liquid port 3, the liquid inlet pipe 4 provided at the upper end of the liquid inlet port 2, and the liquid outlet pipe 5 arranged at the lower end of the liquid outlet port 3, wherein the valve body 1 is in the shape of a square prism, and the valve body 1 A valve cavity 6 is provided inside, the liquid inlet 2 and the four liquid outlets 3 communicate with the valve cavity 6 respectively, the liquid inlet pipeline 4 communicates with the liquid inlet 2, and the liquid outlet pipeline 5 It communicates with the liquid outlet 3.

[0041] see Figure 5-Figure 7 , the middle part of the valve chamber 6 is provided with a divider baffle 7 for guiding the liquid to flow around, there is a gap between the ...

Embodiment 2

[0062] see Figure 12 , the other structures in this embodiment are the same as in Embodiment 1, the difference is that the splitter baffle 7 is directly fixed on the mounting boss 13, and the elastic diaphragm 9 is rotatably arranged on the side of the splitter baffle 7. At the edge, the distance between two adjacent installation bosses 13 is the same as the width of the elastic diaphragm 9 . By arranging the above-mentioned structure, on the one hand, the airtightness between the elastic diaphragm 9 and the shunt partition 7 can be further improved, and the distance between two adjacent bosses is the same as the width of the elastic diaphragm 9, which can also ensure that the installation convex The tightness between the platform 13 and the diaphragm ensures the airtightness of the entire communication port 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com