Heavy-duty vehicle DPM tail gas after-treatment device and heavy-duty vehicle

A technology for after-treatment of exhaust gas and heavy-duty vehicles, which is applied to the electronic control of exhaust treatment devices, diagnostic devices for exhaust treatment devices, and exhaust gas treatment. The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The patent of the present invention will be described in detail below with reference to the accompanying drawings and in conjunction with embodiments.

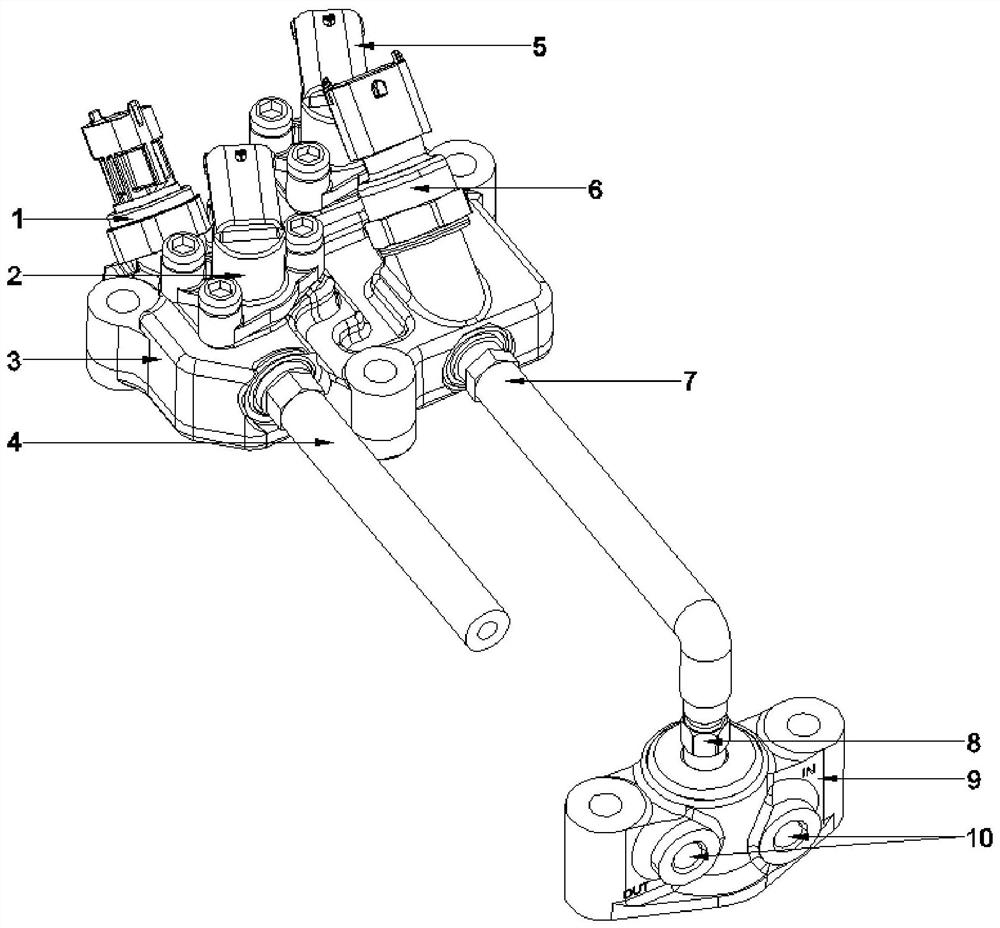

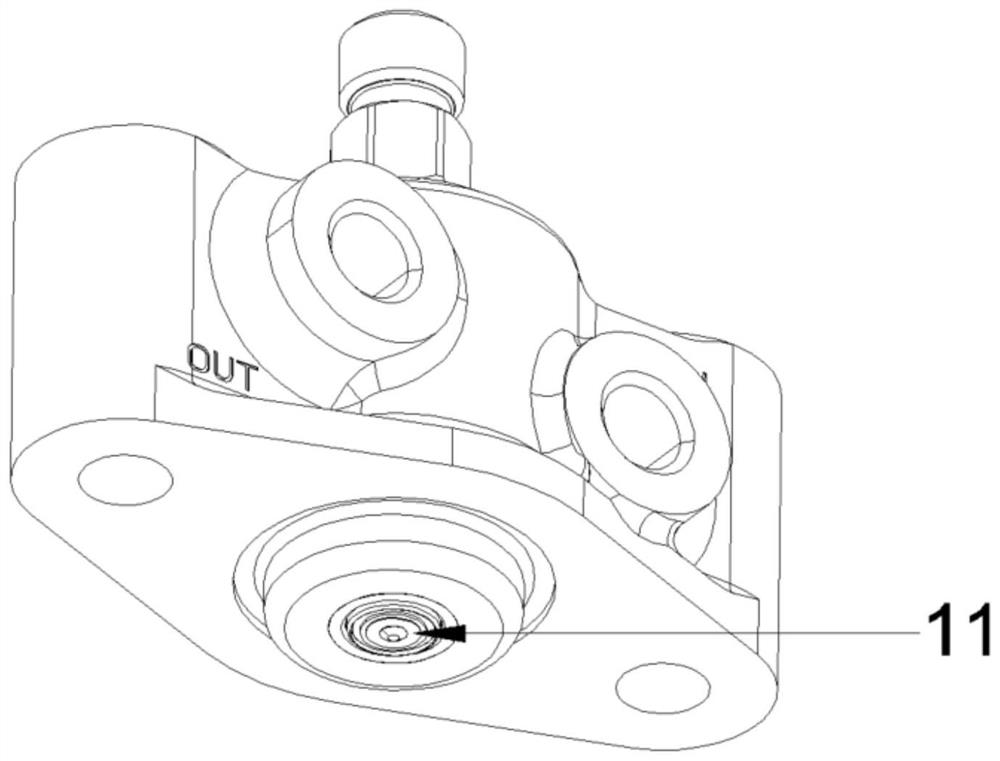

[0030] like figure 1 As shown, a heavy-duty vehicle DPM exhaust after-treatment device in this embodiment includes: a metering unit and an injection unit, and the metering unit includes: a first housing 3 with an oil inlet 4 on the first housing 3 , the oil outlet 7 and the oil passage connecting the oil inlet 4 and the oil outlet 7; the shut-off valve 2, the shut-off valve 2 is installed on the oil inlet 4; the injection valve 5, the injection The valve 5 is arranged on the oil passage; the temperature and pressure sensor 1 is arranged on the oil passage and is located between the shut-off valve 2 and the injection valve 5; the injection unit is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com