Vacuum sound insulation and heat preservation board for buildings

A sound insulation and heat preservation, vacuum technology, applied in the field of building sound insulation and heat preservation, can solve problems such as poor sound insulation effect, inconvenient construction, water damage, etc., and achieve the effect of improving vibration damping and buffering effect, improving sound insulation effect, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

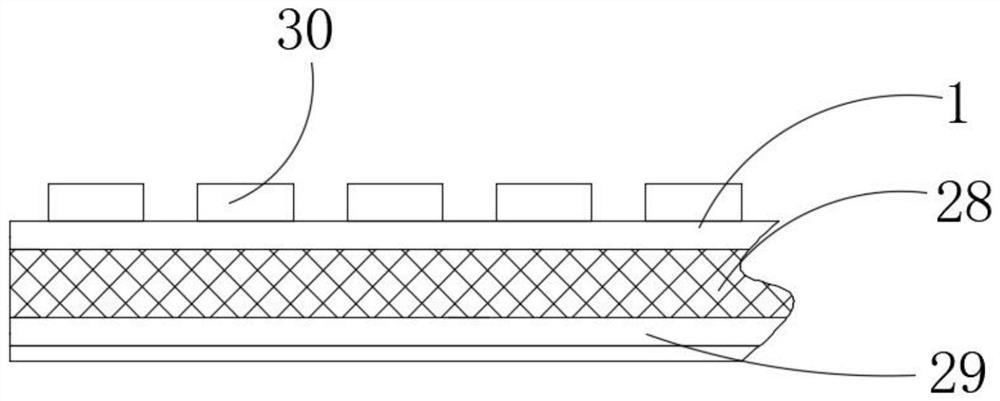

[0033] Such as figure 1 As shown, a vacuum sound-insulation insulation board for buildings, which includes a geothermal pipe fixing plate 1, a support layer 28 and a shock absorbing layer 29 from top to bottom, and a plurality of pipe clamping blocks are arranged in a matrix on the geothermal pipe fixing plate 1 30. The support layer 28 is specifically configured as a honeycomb panel, and the shock-absorbing layer 29 is specifically configured as a shock-absorbing sponge layer;

[0034] Exemplarily, the insulation layer is the bottom layer of the floor heating. The material is foam insulation board or extruded board with a thickness of 2cm. It is mainly used to prevent the heat of the floor heating pipe from dissipating downward. The heating pipe under the floor heats the floor to the surface temperature of 18 to 32 degrees Celsius, and radiates heat evenly to the room to achieve the heating effect;

[0035] The role of the low-temperature radiant floor is to prevent the heat...

Embodiment 2

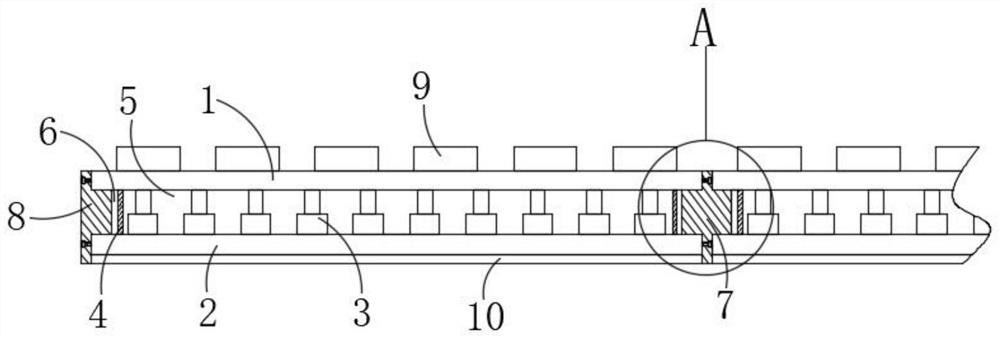

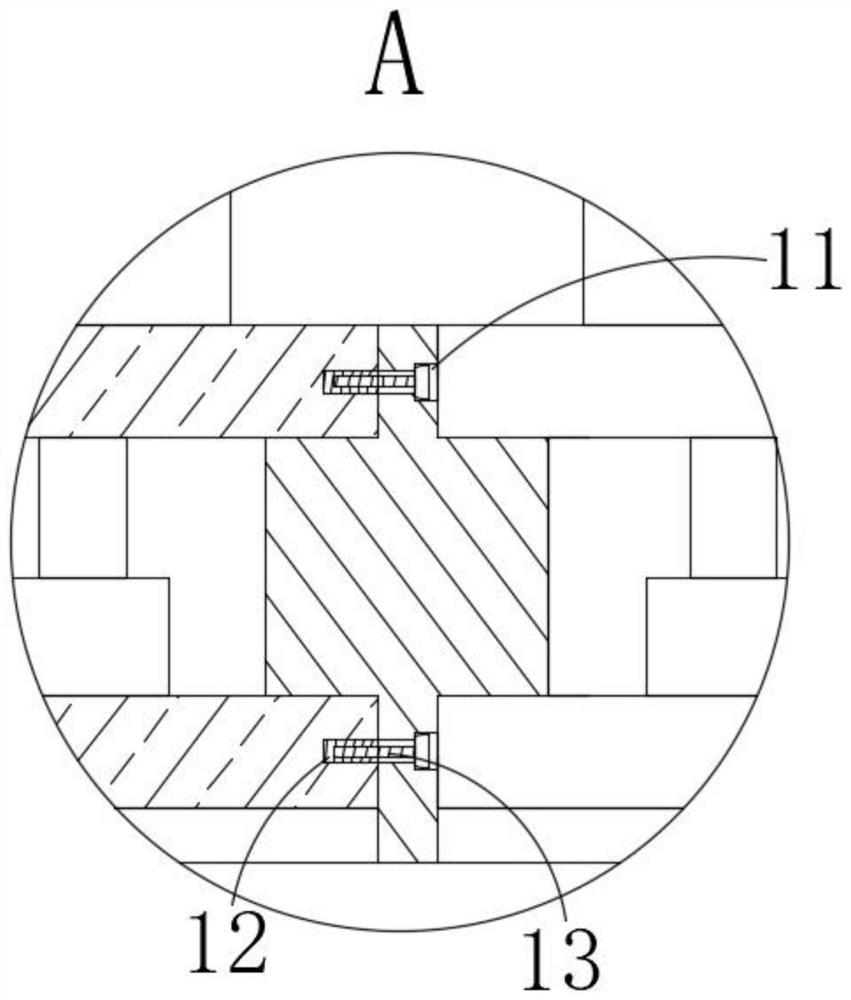

[0040] Such as Figure 2-4 As shown, a vacuum sound insulation and thermal insulation board for buildings includes a geothermal pipe fixing plate 1, a bottom backing plate 2 and a vacuum elastic support 3 between the geothermal pipe fixing plate 1 and the bottom backing plate 2, and the geothermal pipe fixing plate 1 It is divided into a vacuum part 5 and a connecting part 6 by a partition plate 4 between it and the bottom backing plate 2. The vacuum elastic support 3 is located inside the vacuum part 5, and the inside of the connecting part 6 is respectively provided with a plate splicing part 7 and a plate edge banding 8, and the plate splicing piece 7 and the plate edge banding piece 8 are connected and fixed with the geothermal pipe fixing plate 1 and the bottom backing plate 2 through the fixing screws 13, and the upper surface of the geothermal pipe fixing plate 1 is integrally formed with the first Block 9, the lower surface of the base plate 2 is fixedly bonded with a ...

Embodiment 3

[0051] The difference from Example 1 is that, as Figure 5-6 As shown, the building vacuum sound insulation board also includes a second block 21, the upper surface of the geothermal pipe fixing plate 1 is provided with grooves 20 in an equidistant array, and the lower end of the second block 21 is integrally formed with a metal insertion column 22 , the inner bottom of the groove 20 is provided with an NdFeB magnet piece 23, and the lower end of the metal plug-in post 22 is adsorbed and fixed on the NdFeB magnet piece 23;

[0052] The second clamping block 21 is set as a circular clamping block, and the side of the second clamping block 21 is arranged in an arc shape;

[0053] Through the above design, in actual use, according to the actual pipe arrangement requirements of the floor heating pipeline, the second clamping block 21 can be inserted into the appropriate groove 20, and the pipeline can be limited and clamped by the second clamping block 21, and because The setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com