Nano anti-dazzle glass for display screen

An anti-glare, display screen technology, applied in coatings and other directions, can solve the problems of corrosive pharmaceutical waste water pollution, environmental and ecological damage, wear-resistant yield rate and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

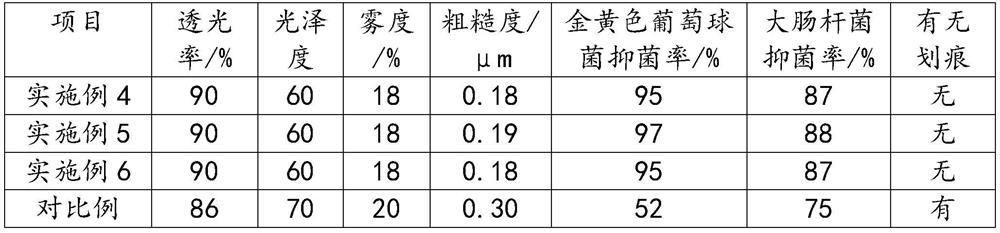

Examples

Embodiment 1

[0029] Nanospheres are made by the following steps:

[0030]Step A1. Add 10.25 g of hexadecane chloride and 4.7 g of 1-vinylimidazole into a single-necked flask, control the reaction temperature at 40°C, and stir for 72 hours at a rotational speed of 80 r / min. Add 20mL of diethyl ether and ethyl acetate to mix solvent a uniformly according to the volume ratio of 1:1, under the condition of rotating speed 30r / min, stir for 1min and then let it stand for 2h, filter, continue to precipitate the filtrate with solvent a once, filter, and combine the filter cake, Dry in a vacuum oven at 25°C for 24 hours to obtain Intermediate 1;

[0031] Step A2, add 1.5g of Intermediate 1 and 10mL of deionized water into a single-necked flask, stir for 5min at a rotational speed of 30r / min, increase the rotational speed to 100r / min, and add 12mL of 5% fluorine dropwise into the single-necked flask For the silver chloride solution, control the dropping rate to 1 drop / second. After the dropwise add...

Embodiment 2

[0037] Nanospheres are made by the following steps:

[0038] Step A1. Add 10.25g of hexadecane chloride and 4.7g of 1-vinylimidazole into a single-necked flask, control the reaction temperature at 40°C, and stir for 72 hours at a speed of 100r / min. After the reaction, add 20mL of diethyl ether into the single-necked flask Mix solvent a evenly with ethyl acetate at a volume ratio of 1:1, under the condition of rotation speed 40r / min, stir for 1min and let it stand for 2h, filter, continue to precipitate the filtrate with solvent a once, filter, combine the filter cake, and vacuum at 28°C Dry in an oven for 24 hours to obtain Intermediate 1;

[0039] Step A2, add 1.5g of intermediate 1 and 10mL of deionized water into a single-necked flask, stir for 5min at a rotational speed of 30r / min, increase the rotational speed to 100r / min, and add 14mL of 5% fluorinated water dropwise into the single-necked flask For silver solution, control the dropping rate to 2 drops / second. After the...

Embodiment 3

[0045] Nanospheres are made by the following steps:

[0046] Step A1. Add 10.25g of hexadecane chloride and 4.7g of 1-vinylimidazole into a single-necked flask, control the reaction temperature at 40°C, and stir for 72 hours at a speed of 120r / min. After the reaction, add 20mL of diethyl ether into the single-necked flask Mix solvent a evenly with ethyl acetate according to the volume ratio of 1:1, under the condition of rotating speed 60r / min, stir for 1min and let it stand for 2h, filter, continue to precipitate the filtrate with solvent a once, filter, combine the filter cake, and vacuum at 30°C Dry in an oven for 24 hours to obtain Intermediate 1;

[0047] Step A2, add 1.5g of intermediate 1 and 10mL of deionized water into a single-necked flask, stir for 5min at a rotational speed of 30r / min, increase the rotational speed to 100r / min, and drop 15mL of 5% fluorinated water into the single-necked flask For silver solution, control the dropping rate to 3 drops / second. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com