Environment-friendly and energy-saving temperature control system for injection molding cooling water

A technology of environmental protection, energy saving and temperature control system, which is applied in the direction of cleaning non-rotating equipment, cleaning heat transfer devices, lighting and heating equipment, etc., can solve problems such as blockage of cooling pipes, and achieve the effect of avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

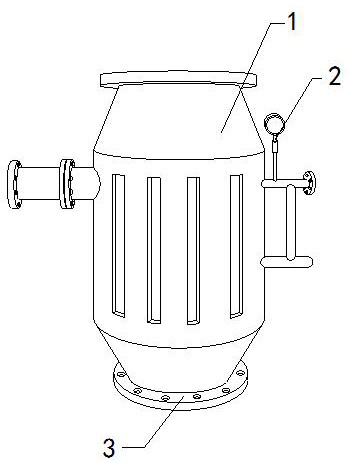

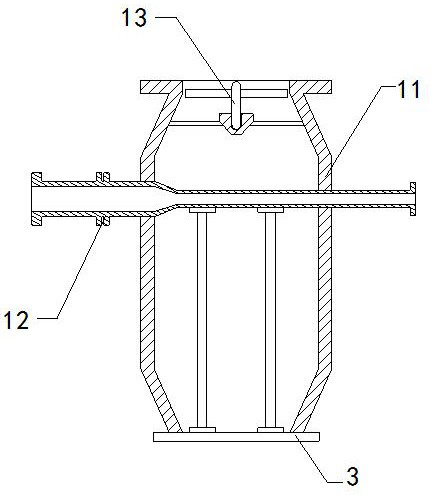

[0029] The invention provides an environment-friendly and energy-saving temperature control system for injection molding cooling water, the structure of which includes a temperature controller 1, a pressure gauge 2, and a base 3. The bottom of 1 is welded to the upper surface of the base 3; the thermostat 1 includes an outer frame 11, a heat dissipation pipe 12, and a heat dissipation fan 13, and the heat dissipation pipe 12 runs through the inner position of the outer frame 11, and the heat dissipation fan 13 It is movably engaged with the upper end of the inner wall of the outer frame 11 .

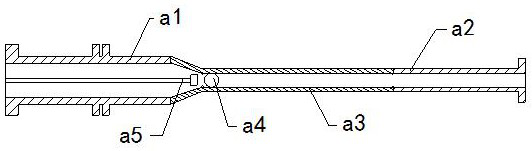

[0030] Wherein, the heat dissipation pipe 12 includes a water inlet pipe a1, a water outlet pipe a2, an intermediate connecting pipe a3, an outer rolling ball a4, and a suction rod a5. The right side of the water inlet pipe a1 is welded to the left side of the intermediate connecting pipe a3. The water pipe a2 is fixed on the rig...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037] Wherein, the driving groove a42 includes a lower connecting plate c1, a linkage plate c2, and an elastic strip c3, the linkage plate c2 is hingedly connected to the center of the upper surface of the lower connecting plate c1, and the elastic strip c3 is installed on the bottom of the linkage plate c2 Between the upper surface of the lower connecting plate c1, the swinging force generated by the rotation of the mechanism can make the linkage plate c2 swing along the lower connecting plate c1, so that the linkage plate c2 can shake off the scale falling on its surface .

[0038]Wherein, the linkage plate c2 includes a blocking block c21, an inner connection cavity c22, and a plate c23. The blocking block c21 is fixed on the inner wall of the inner connection cavity c22 near the upper end, and the inner connection cavity c22 penetrates the inner position of the plate c23. There are four inscribed cavities c22, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com