On-film transplanting machine

A technology of transplanting machine and machine body, which is applied in the field of transplanting machines, and can solve problems such as high soil viscosity, soil squeezed into the seedling guide tube, and slow water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

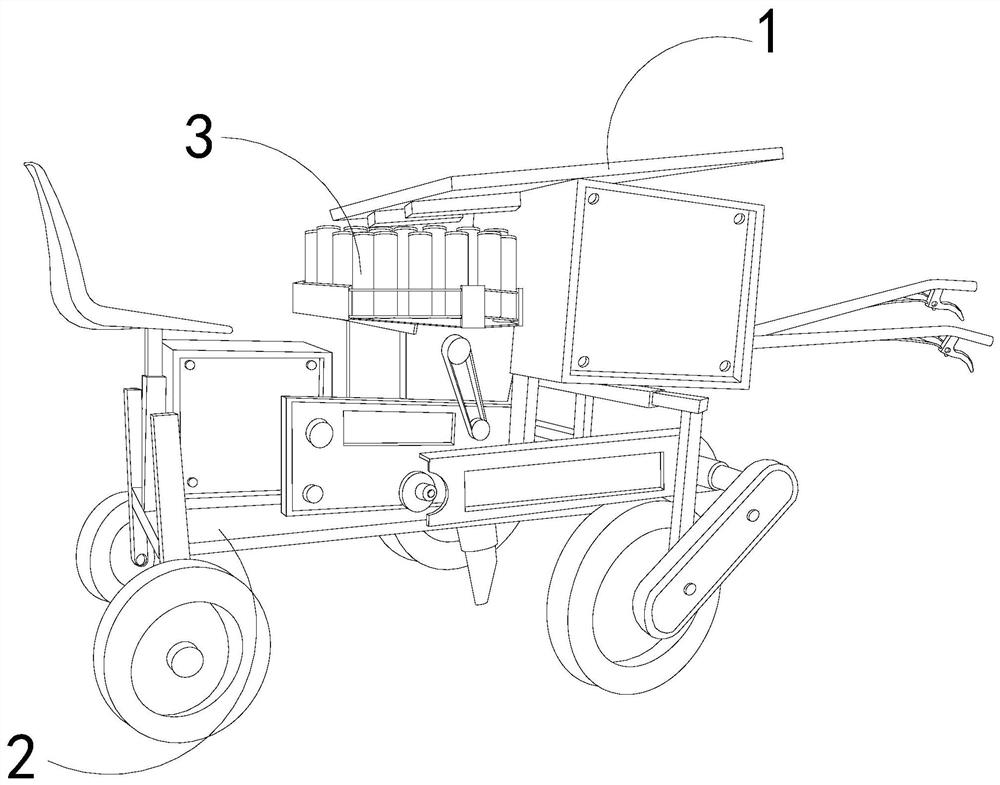

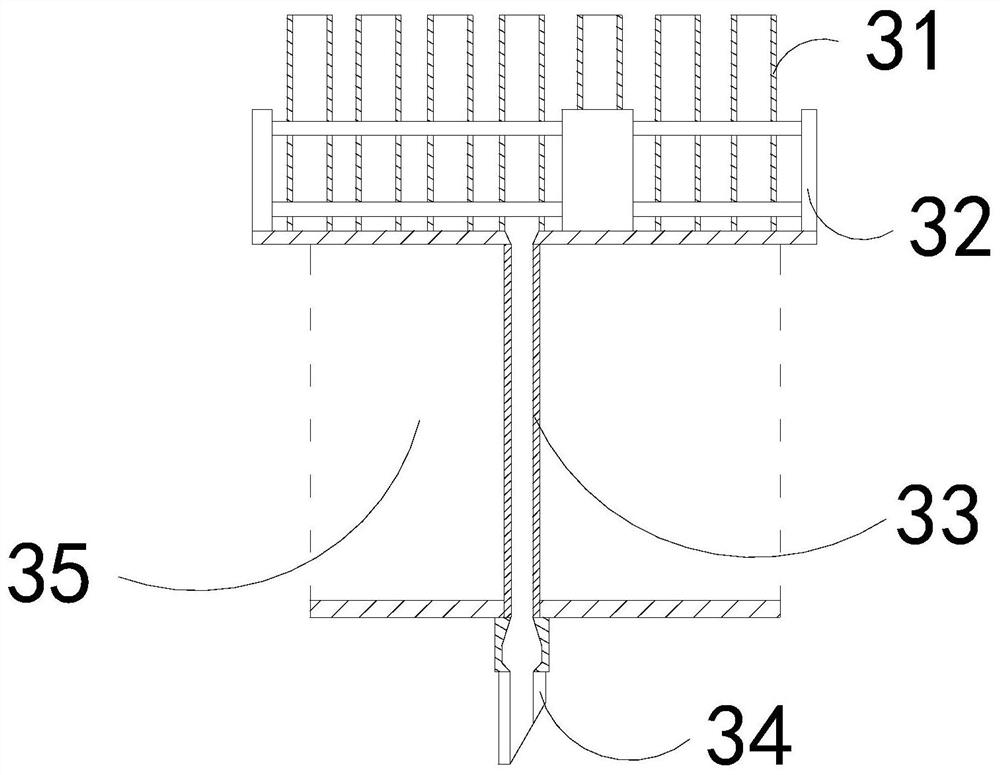

[0029] The invention provides a transplanting machine on a film, the structure of which includes an upper plate 1, a body 2, and a transplanting mechanism 3, the bottom of the upper plate 1 is connected with the upper end of the body 2, and the transplanting mechanism 3 runs through In the inner position of the body 2; the transplanting mechanism 3 includes a feeding pipe 31, a rotating disk 32, a fixed pipe 33, a seedling guide 34, and a partition 35, and the bottom of the feeding pipe 31 is installed on the inner wall of the rotating disk 32 At the bottom position, the bottom of the rotating disk 32 is welded to the upper end of the partition plate 35, the upper end of the fixed pipe 33 is embedded in the inner position of the rotating disk 32, and the top of the seed guide 34 is embedded and connected with the fixed pipe 33.

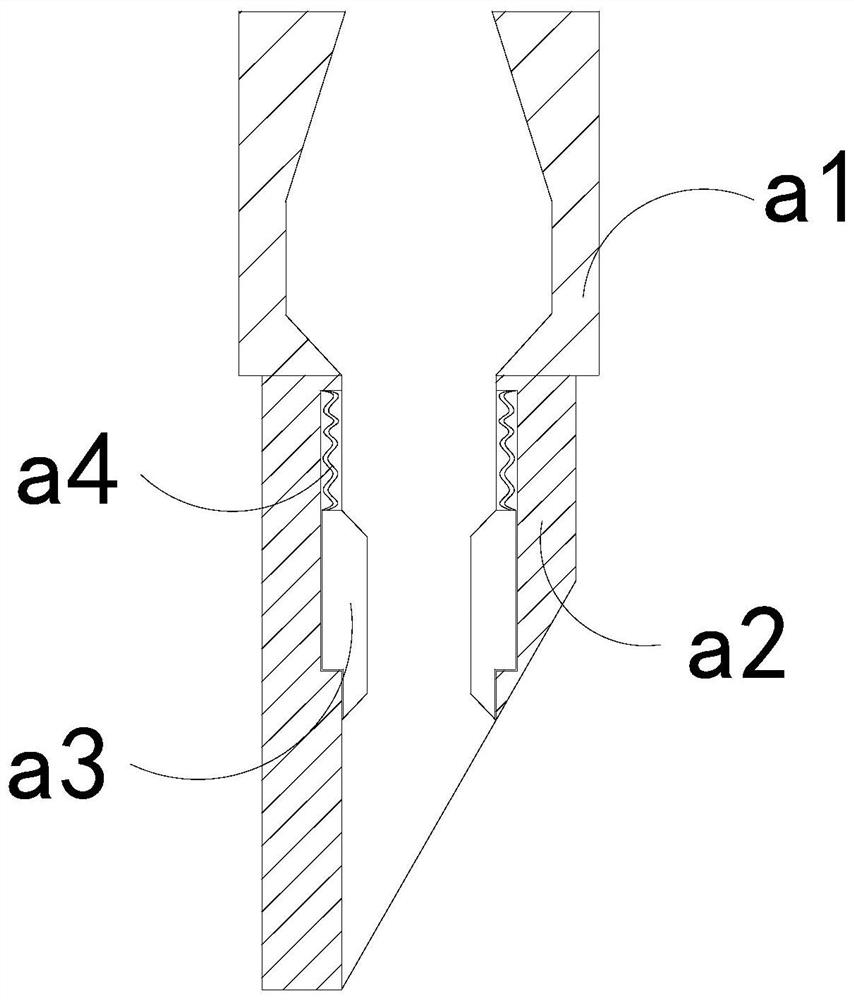

[0030] Wherein, the guide head 34 includes a frame a1, a lower frame a2, a sliding plate a3...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037] Wherein, the grasping force groove a32 includes an extension block c1, a linkage rod c2, an extension bar c3, and a rear frame c4, the left side of the extension block c1 is connected with the right side of the linkage rod c2, and the linkage The rod c2 is slidably matched with the inside of the rear frame c4, and the push bar c3 is installed between the inner wall of the rear frame c4 and the left side of the linkage rod c2, and the vibration generated by the expansion and contraction of the mechanism can make the extension block c1 The linkage rod c2 slides outward along the rear frame c4 under cooperation, so that the overhanging block c1 can push out the soil inside the rear frame c4.

[0038] Wherein, the overhanging block c1 includes a central connection plate c11, an external extrusion strip c12, and a side swing plate c13, and the external extrusion strip c12 is fixed between the side of the central connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com