Hard alloy milling cutter machining device capable of conveniently adjusting cutting depth

A technology of cutting depth and hard alloy, which is applied in metal processing equipment, metal processing machinery parts, sawing machine devices, etc., can solve the problems of scrapped milling cutters, uncontrollable depth of grooves, and easy occurrence of offset, etc., to improve cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

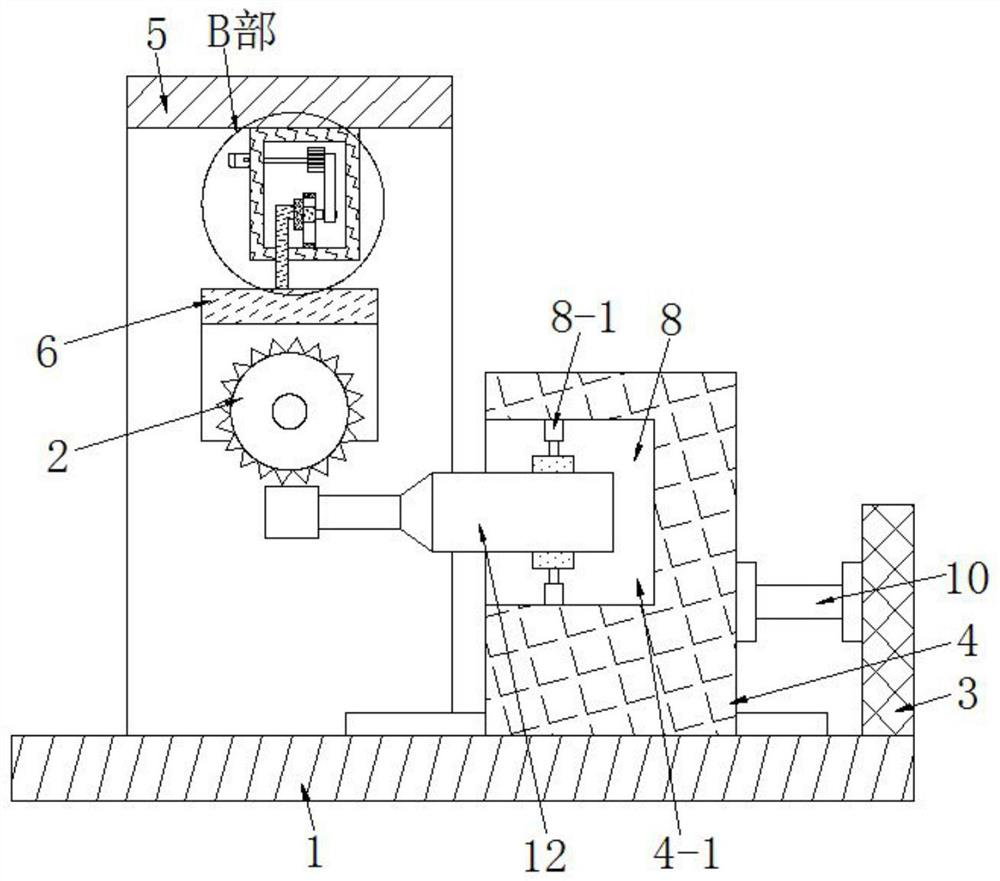

[0030] see as Figure 1-Figure 9As shown, the technical solution adopted in this specific embodiment is: it includes a working base 1 and a saw blade 2, and the working base 1 is provided with a saw blade 2; it also includes a fixed block 3, a clamping seat 4, and a support 5 , support frame 6, fixed seat 7, clamping mechanism 8 and driving mechanism 9, the upper end of the right side of the working base 1 is welded and fixed with a fixed block 3, and the left side of the fixed block 3 utilizes screws to fix the cylinder 10 of model TN20, A clamping seat 4 is welded and fixed on the pushing end of the cylinder 10, and a guide rail 11 is welded and fixed symmetrically front and rear on the working base 1. A placement slot 4-1 is provided, the knife handle in the tool 12 is set in the placement slot 4-1, and a clamping mechanism 8 is arranged between the knife handle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com