Axial vertical drilling machine

A technology of drilling machine and drilling mechanism, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. The drill bit is easy to be damaged and other problems, so as to facilitate quick maintenance and processing, facilitate automatic production, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

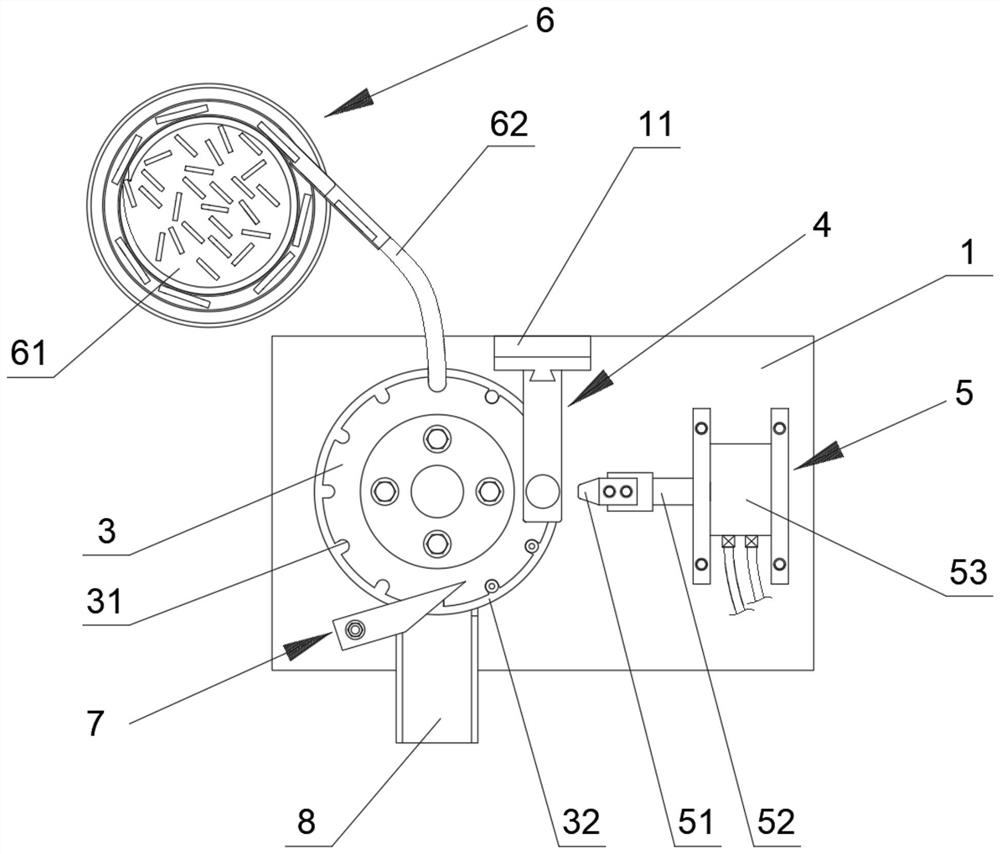

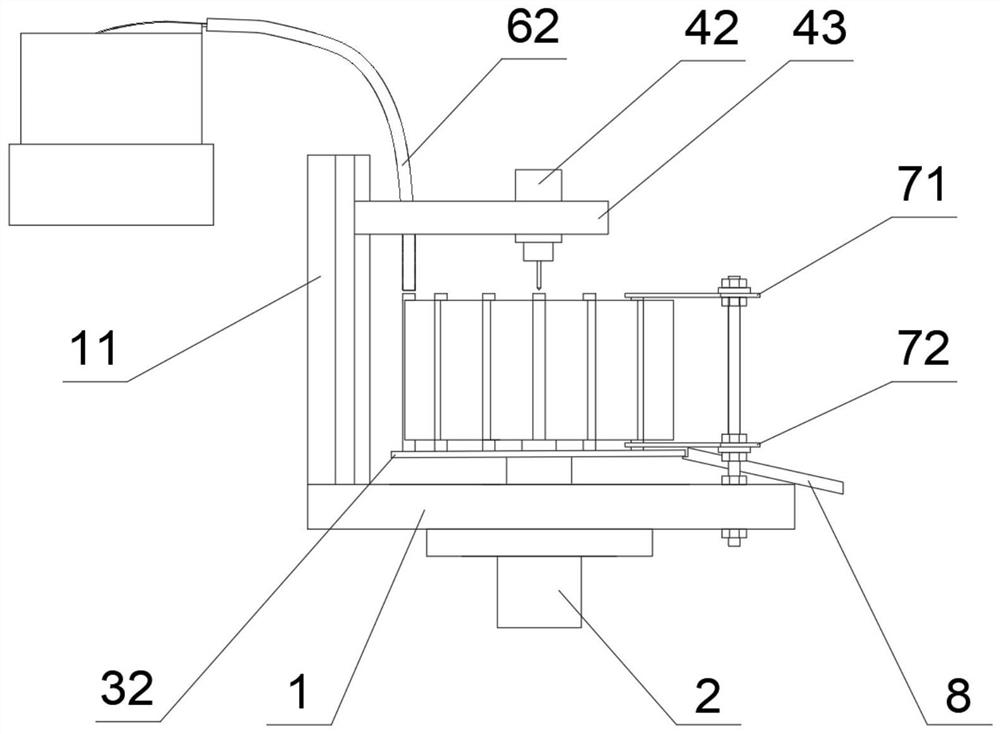

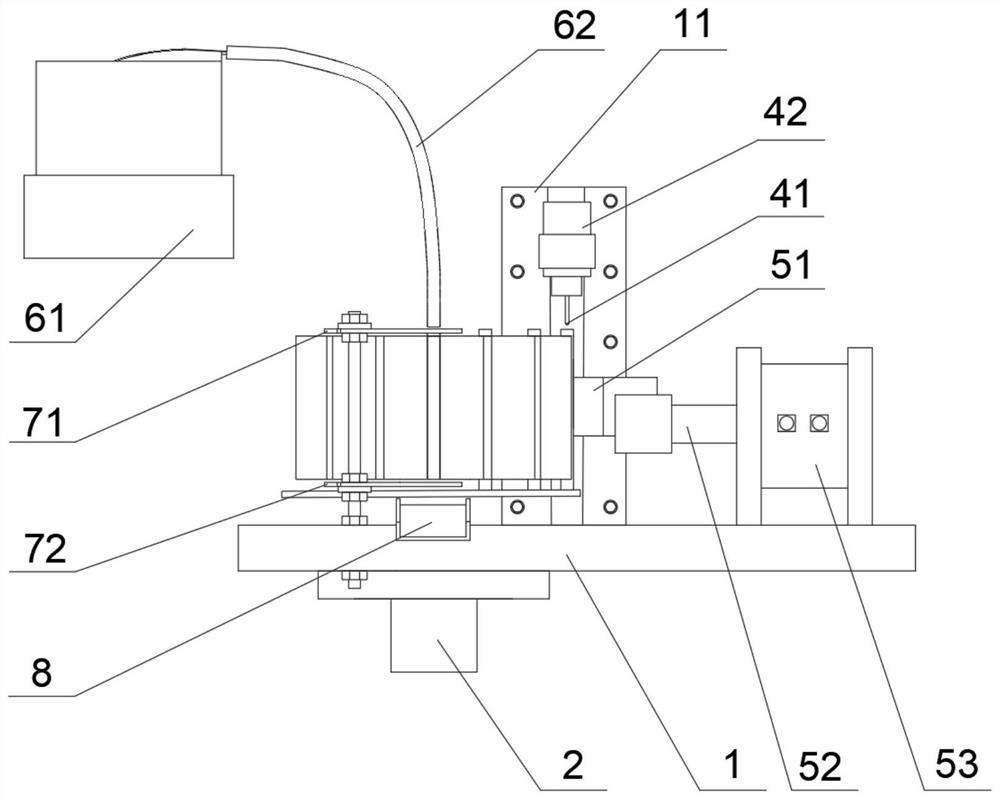

[0022] see Figures 1 to 3 , an axial vertical drilling machine, comprising a base 1, a processing turntable 3 fixed on the base 1 and controlled to rotate by a first motor 2, a drilling mechanism 4 axially above the outer circumference of the processing turntable 3 and The fastening mechanism 5 on the radially outer side of the processing turntable 3; the outer circumference of the processing turntable 3 is distributed in an array with a plurality of U-shaped opening slots 31 that penetrate axially, and the U-shaped openings of the locking slots 31 face the radially outer side of the processing turntable 3 ; The fastening mechanism 5 is located on the radially outside of the corresponding slot 31 below the drilling mechanism 4. When the drilling mechanism 4 drills the cylindrical hardware in the slot 31, the fastening mechanism 5 Radial ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com