Cooling method for controlling lateral bending deformation after rolling of marine L-shaped steel

A cooling method and side control technology, applied in metal rolling, temperature control, metal rolling, etc., to achieve good realizability, increase yield, and reduce severe side bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A cooling method for controlling side bending deformation of marine L-shaped steel after rolling, comprising the following steps:

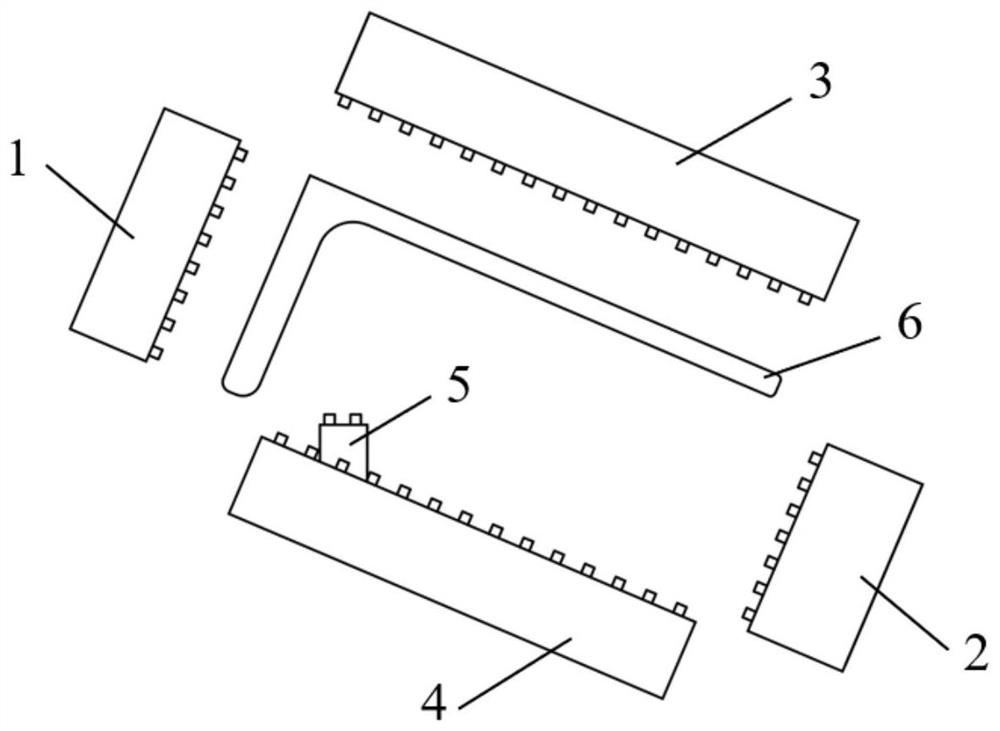

[0022] Step 1: After finishing the finish rolling of the billeted L-shaped steel billet for marine use, the L-shaped steel for marine use 6 after final rolling is obtained, followed by rapid cooling treatment, and different strengths are applied to the three parts of the L-shaped marine steel 6 after final rolling cooling, such as figure 1 As shown, the nozzles of No. I water tank 1 and No. II water tank 2 are used to water-cool the positions on both sides of the panel, the nozzles of No. III water tank 3 and No. IV water tank 4 are used to water-cool the positions on both sides of the web, and the nozzles of No. V water tank 5 are used. The nozzle is water-cooled at the R angle position, and the cooling intensity is: the cooling intensity at the R angle position > the cooling intensity at both sides of the panel > the cooling intensity at ...

Embodiment 2

[0032] A cooling method for controlling side bending deformation of marine L-shaped steel after rolling, comprising the following steps:

[0033] Step 1: after finishing rolling of the billeted L-shaped steel billet for marine use, the L-shaped steel for marine use after final rolling is obtained, followed by rapid cooling treatment, and different intensities of cooling are applied to the three parts of the L-shaped marine steel after final rolling, The cooling method is the same as in Example 1, and the cooling intensity is: the cooling intensity at the R angle position > the cooling intensity at both sides of the panel > the cooling intensity at both sides of the web plate, the overall cooling rate of L-shaped steel for ships is 50°C / s, and the cooling time is is 6s, and the final cooling temperature is 620°C, and the marine L-shaped steel after final cooling is obtained;

[0034] Step 2: After the final cooling, the marine L-shaped steel returns to temperature at 711-719°C,...

Embodiment 3

[0043] A cooling method for controlling side bending deformation of marine L-shaped steel after rolling, comprising the following steps:

[0044]Step 1: after finishing rolling of the billeted L-shaped steel billet for marine use, the L-shaped steel for marine use after final rolling is obtained, followed by rapid cooling treatment, and different intensities of cooling are applied to the three parts of the L-shaped marine steel after final rolling, The cooling method is the same as in Example 1, and the cooling intensity is: the cooling intensity at the R angle position > the cooling intensity at both sides of the panel > the cooling intensity at both sides of the web plate, the overall cooling rate of marine L-shaped steel is 70°C / s, and the cooling time is is 3s, the final cooling temperature is 670°C, and the marine L-shaped steel after final cooling is obtained;

[0045] Step 2: After the final cooling, the marine L-shaped steel returns to temperature at 754-765°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bending amount | aaaaa | aaaaa |

| Bending amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com