Preparation method and application of MoS2 and hole extraction functionalized carbon quantum dot co-modified Ag-In-Zn-S quantum dot

A technology of ag-in-zn-s and quantum dots, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of limited catalytic activity and low charge separation efficiency, and achieve technological Simple, convenient for mass production, and the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

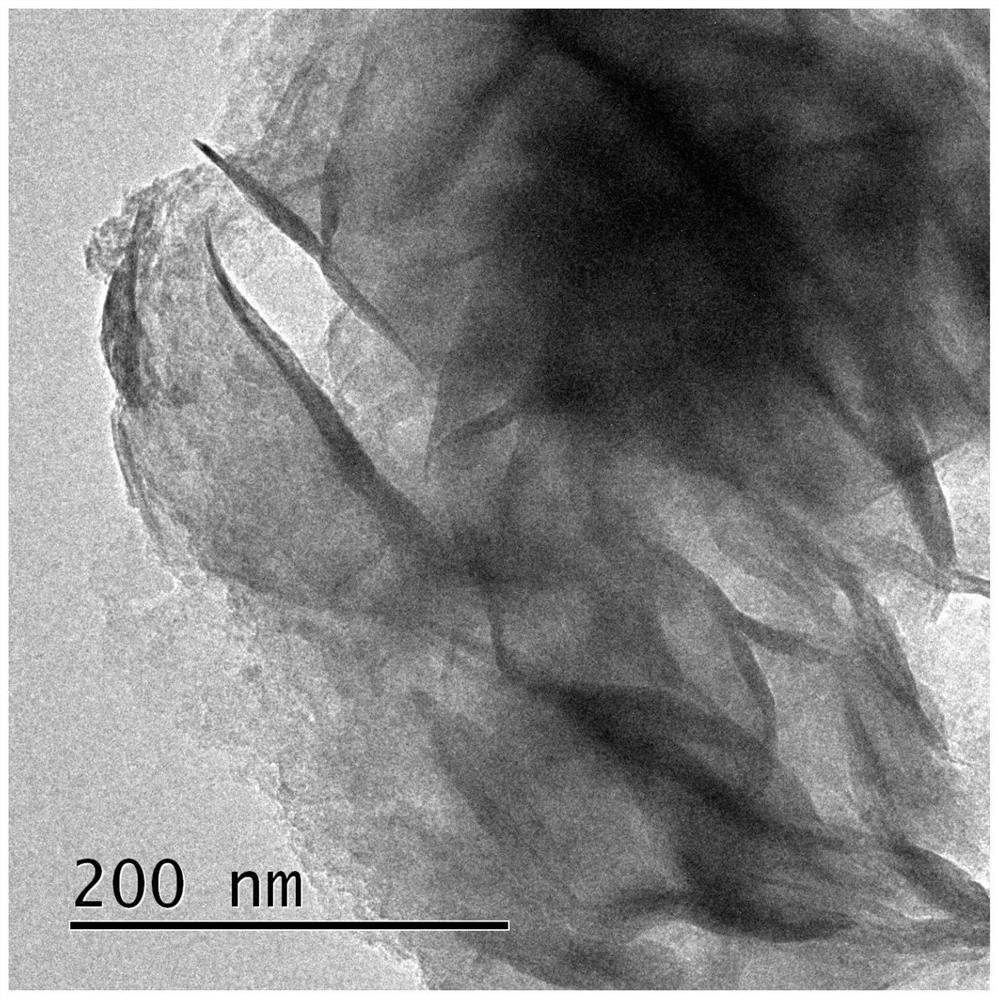

Image

Examples

Embodiment 1

[0028] A kind of MoS 2 Co-modified Ag-In-Zn-S quantum dots (MoS 2 / AIZS / fCDs) preparation method, comprising:

[0029] A. Weigh 0.34 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine in 5.5 mL of water, and adjust the pH value to 8.5 with 1M NaOH solution;

[0030]B. Continue to add 3.48mmol of fCDs precursor and 3.2mmol of thioacetamide to the above solution, stir evenly by ultrasonic, conduct a hydrothermal reaction at 110°C for 4h, cool to room temperature, centrifuge and wash to prepare AIZS / fCDs;

[0031] C. Pipette 100 mg of the prepared AIZS / fCDs and 9 mg of MoS 2 Dissolve in 10mL water, stir mechanically for 12h, centrifuge and wash to obtain MoS 2 / AIZS / fCDs.

[0032] Evaluation of the photocatalytic activity of the photocatalyst: After calculation, the MoS prepared in this example 2 The hydrogen production rate of / AIZS / fCDs is 5.1mmol / g / h.

Embodiment 2

[0034] A kind of MoS 2 Co-modified Ag-In-Zn-S quantum dots (MoS 2 / AIZS / fCDs) preparation method, comprising:

[0035] A. Weigh 0.34 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine in 5.5 mL of water, and adjust the pH value to 8.5 with 1M NaOH solution;

[0036] B. Continue to add 6.96mmol fCDs precursor and 3.2mmol thioacetamide to the above solution, stir evenly with ultrasonic, 110°C hydrothermal reaction for 4h, after cooling to room temperature, centrifuge and wash to prepare AIZS / fCDs;

[0037] C. Pipette 100 mg of the prepared AIZS / fCDs and 9 mg of MoS 2 Dissolve in 10mL water, stir mechanically for 12h, centrifuge and wash to obtain MoS 2 / AIZS / fCDs.

[0038] Evaluation of the photocatalytic activity of the photocatalyst: After calculation, the MoS prepared in this example 2 The hydrogen production rate of / AIZS / fCDs is 5.8mmol / g / h.

Embodiment 3

[0040] A kind of MoS 2 Co-modified Ag-In-Zn-S quantum dots (MoS 2 / AIZS / fCDs) preparation method, comprising:

[0041] A. Weigh 0.34 mmol of silver nitrate, 1.7 mmol of indium nitrate, 0.85 mmol of zinc acetate dihydrate, and 5 mmol of L-cysteine in 5.5 mL of water, and adjust the pH value to 8.5 with 1M NaOH solution;

[0042] B. Continue to add 10.44 mmol of fCDs precursor and 3.2 mmol of thioacetamide to the above solution, stir evenly with ultrasonic, conduct a hydrothermal reaction at 110°C for 4 hours, cool to room temperature, centrifuge and wash to prepare AIZS / fCDs;

[0043] C. Pipette 100 mg of the prepared AIZS / fCDs and 9 mg of MoS 2 Dissolve in 10mL water, stir mechanically for 12h, centrifuge and wash to obtain MoS 2 / AIZS / fCDs.

[0044] Evaluation of the photocatalytic activity of the photocatalyst: After calculation, the MoS prepared in this example 2 The hydrogen production rate of / AIZS / fCDs is 6.3mmol / g / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com