Full-coverage perovskite thin film and preparation method thereof

A perovskite, full-coverage technology used in the field of solar cells to achieve improved optical properties, low cost, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a fully covered perovskite film in an atmospheric environment, comprising the following steps:

[0051] Step 1: Preparation of CH 3 NH 3 PB 3 Precursor

[0052] Measure PbI 2 The amount of 1.005g, CH 3 NH 3 The amount of I is 0.3466g, the amount of DMF is 3ml, magnetic stirring is used for 30min, and the solution method is used to dissolve and fully react to form a yellow precursor.

[0053] Step 2: Deposit CH 3 NH 3 PB 3 film

[0054] CH prepared in step S1 3 NH 3 PB 3 Add it dropwise on the FTO substrate, spin-coat at 1000r / min for 10s, then spin-coat at 2000r / min for 30s, use a pipette gun to pump 200μl of chlorobenzene, and drop it quickly in semi-dry CH for 15s during the last spin-coating 3 NH 3 PB 3 on the film. Finally, the film was annealed at 80°C.

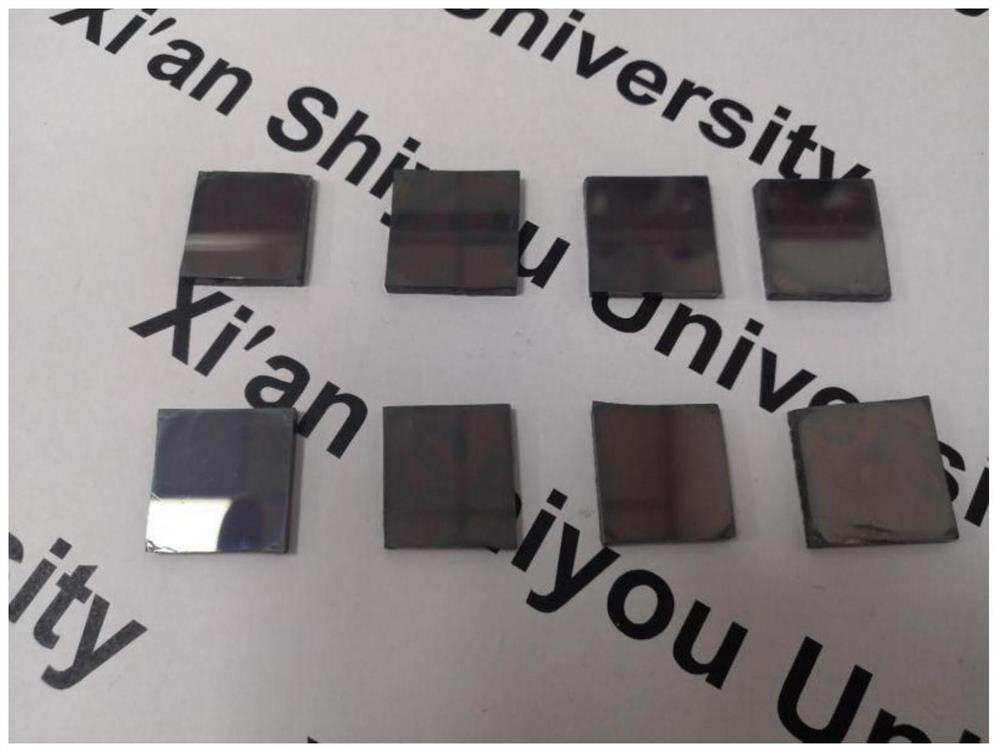

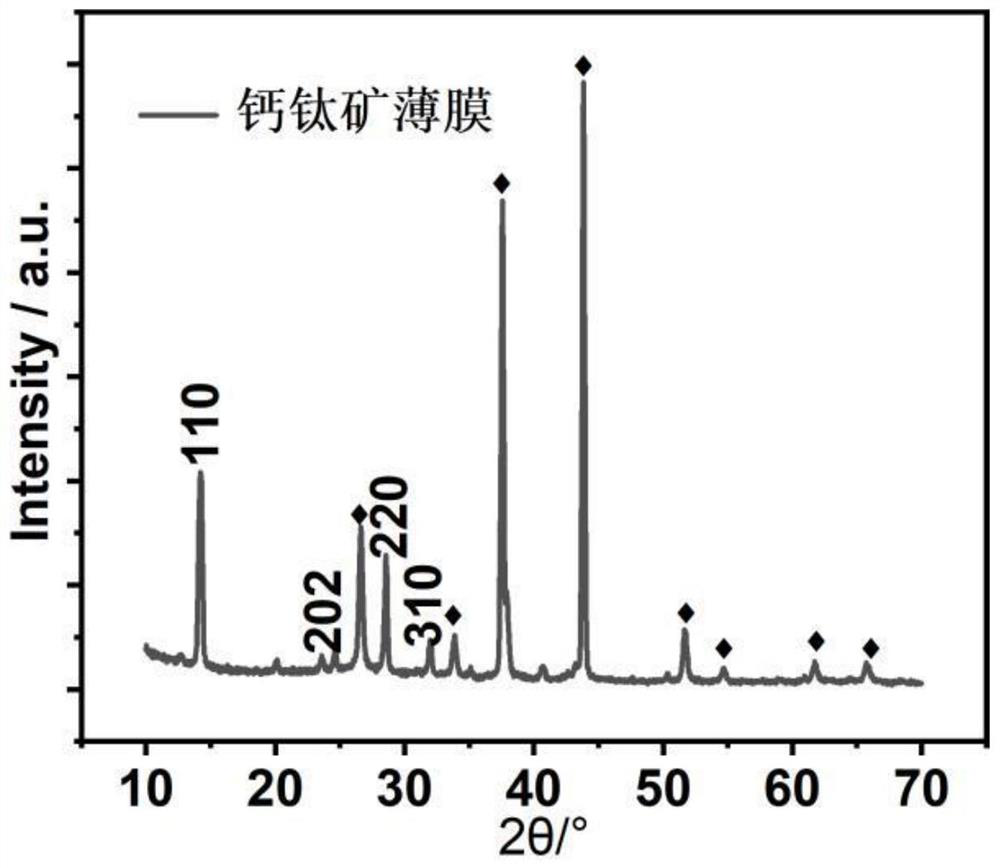

[0055] see figure 1 and figure 2 , for the prepared full coverage CH 3 NH 3 PB 3 Optical photographs of thin films, CH 3 NH 3 PB 3 The thickness of the film is 100 ...

Embodiment 2

[0057] A method for preparing a high-quality perovskite film in an atmospheric environment, comprising the following steps:

[0058] Step 1: Preparation of CH 3 NH 3 PB 3 Precursor

[0059] Measure PbI 2 The amount of 1.005g, CH 3 NH 3 The amount of I is 1.0398g, the amount of DMF is 6ml, magnetically stirred for 50min, and the solution method is used to dissolve and fully react to form a yellow precursor.

[0060] Step 2: Deposit CH 3 NH 3 PB 3 film

[0061] CH prepared in the previous step 3 NH 3 PB 3 Add it dropwise on the FTO substrate, spin-coat at 1000r / min for 10s, then spin-coat at 2000r / min for 30s, use a pipette gun to pump 200μl of CB, and quickly drop it over CH 3 NH 3 PB 3 on the film. Finally, the film was annealed at 80°C.

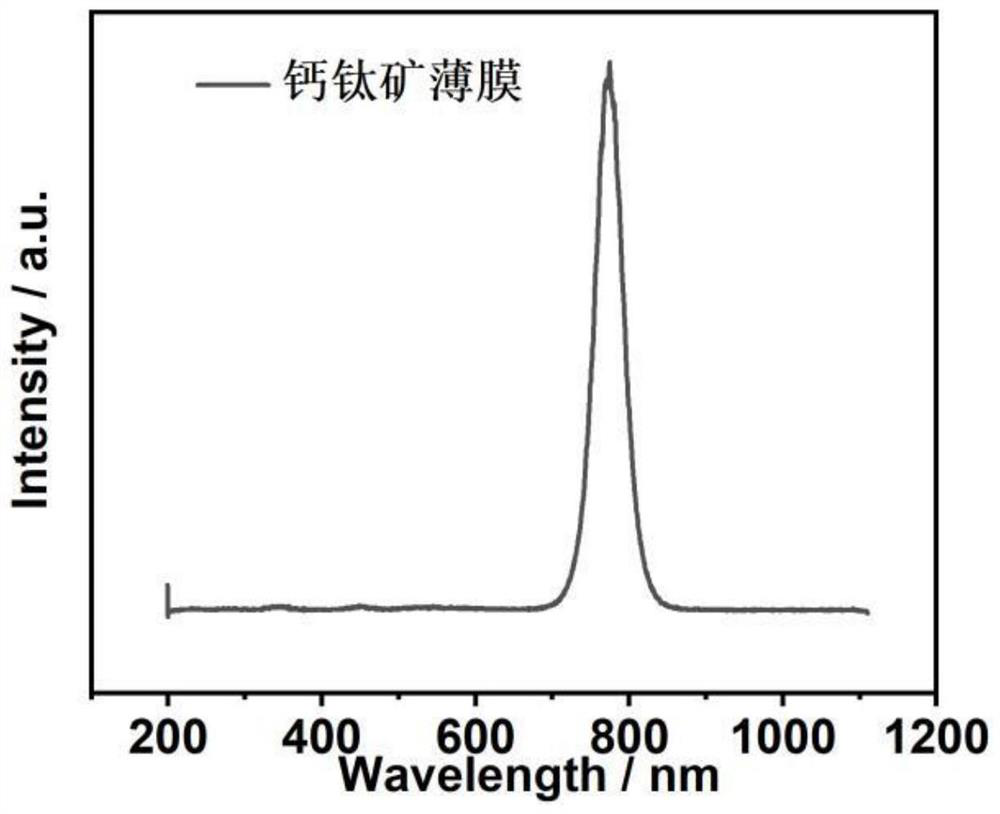

[0062] see image 3 , for the prepared full coverage CH 3 NH 3 PB 3 The PL characterization of the film shows that the relative exciton growth rate is 13747.83a.u. Prepared CH 3 NH 3 PB 3 The thickness of the film is...

Embodiment 3

[0064] A method for preparing a high-quality perovskite film in an atmospheric environment, comprising the following steps:

[0065] Step 1: Preparation of CH 3 NH 3 PB 3 Precursor

[0066] Measure PbI 2 The amount of 1.005g, CH 3 NH 3 The amount of I is 0.3466g, the amount of γ-butyrolactone is 3ml, magnetically stirred for 50min, and the solution method is used to dissolve and fully react to form a yellow precursor.

[0067] Step 2: Deposit CH 3 NH 3 PB 3 film

[0068] CH prepared in the previous step 3 NH 3 PB 3 Add it dropwise on the FTO substrate, spin-coat at 1000r / min for 15s, then spin-coat at 2000r / min for 35s, use a pipette gun to pump 200μl of CB, and drop it quickly for 15s to cover CH 3 NH 3 PB 3 on the film. Finally, the film was annealed at 80°C.

[0069] see Figure 4 , for the prepared full coverage CH 3 NH 3 PB 3 The PL characterization of the film shows that the relative exciton growth rate is 11073.17a.u. Prepared CH 3 NH 3 PB 3 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com