Water ring type vacuum pump efficiency improving device and control method

A water ring vacuum pump and control system technology, applied in the direction of rotary piston pumps, pumps, machines/engines, etc., can solve the problems that affect the negative pressure of the unit, the efficiency of the vacuum pump decreases, and the sealing water of the vacuum pump cannot achieve effective cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, embodiments of the present invention will be described below, and those skilled in the art can easily understand other advantages and efficacy of the present invention, apparently, as described in the present invention. , Not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

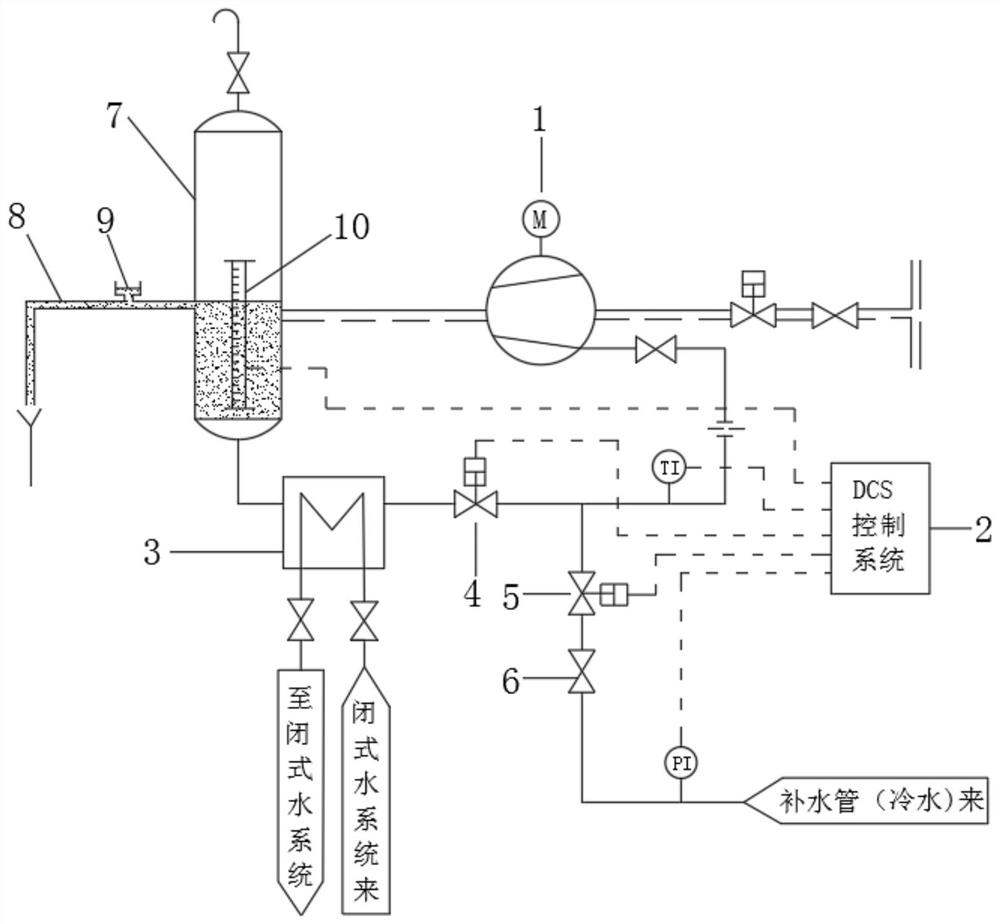

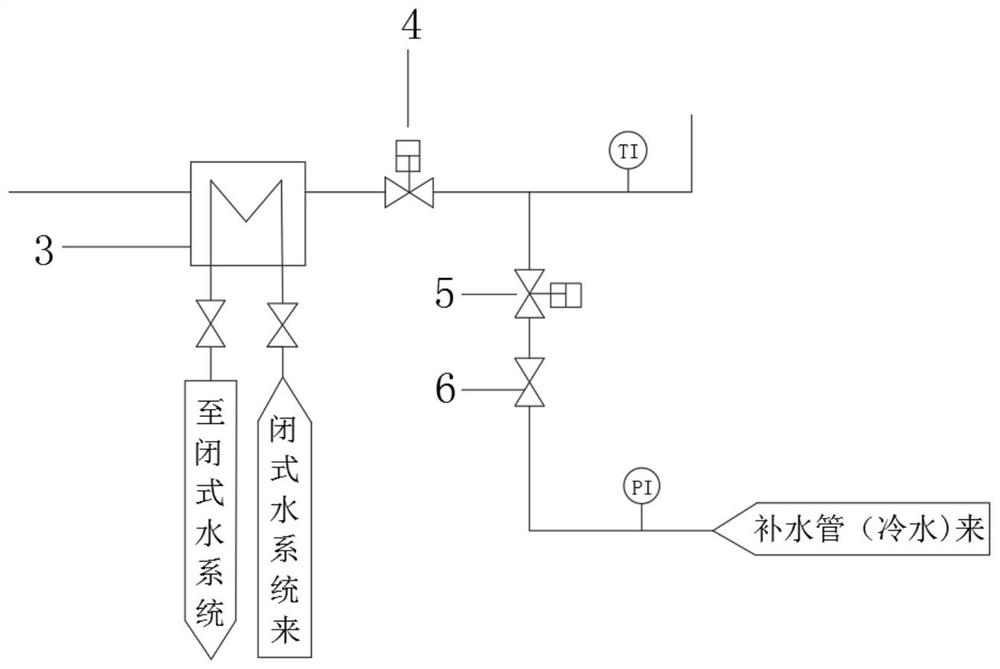

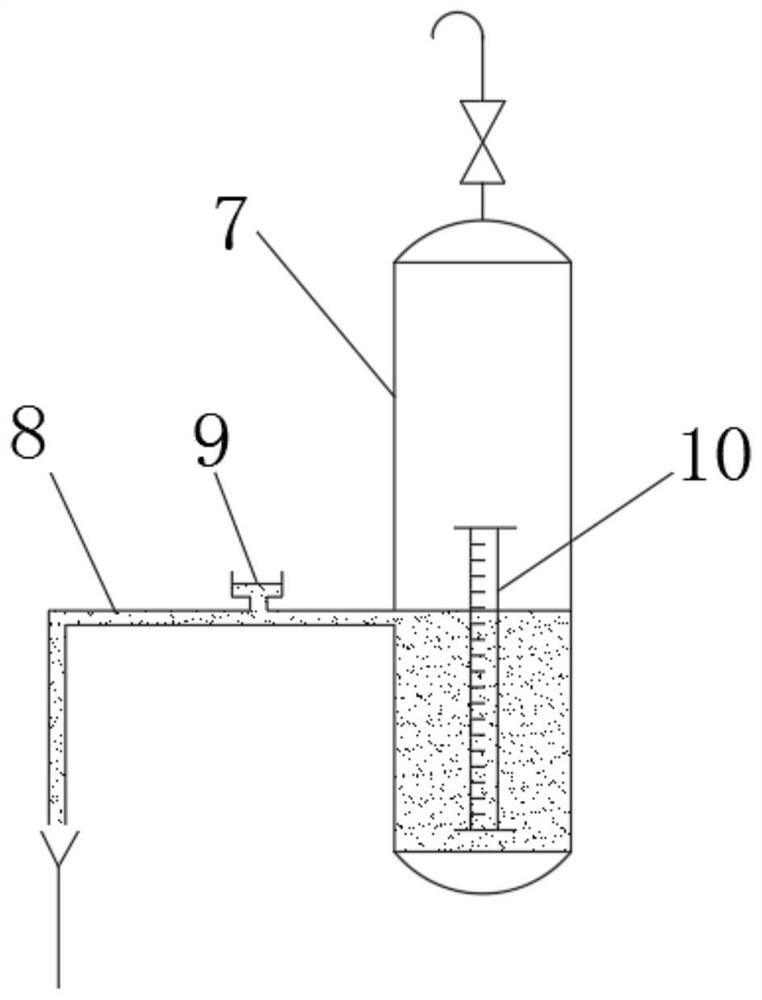

[0027] The technical solution uses a fire power plant using reservoir deep water as a vacuum pump cold water hydration water source as an example: refer to the instructions Figure 1-3 The present invention provides a water ring vacuum pump promotion device including a water loop vacuum pump 1 and a DCS control system 2, and the cold water hydrating pipe is fixed on the rear pipe 3 of the sealed water cooler 3 of the water ring vacuum pump 1. The tube introduces sealing water water hydration water source, and the cold water hydrating pipe is fixed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com