Multifunctional operation rack suitable for tunnel construction

A multi-functional technology for tunnel construction, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as high failure rate and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

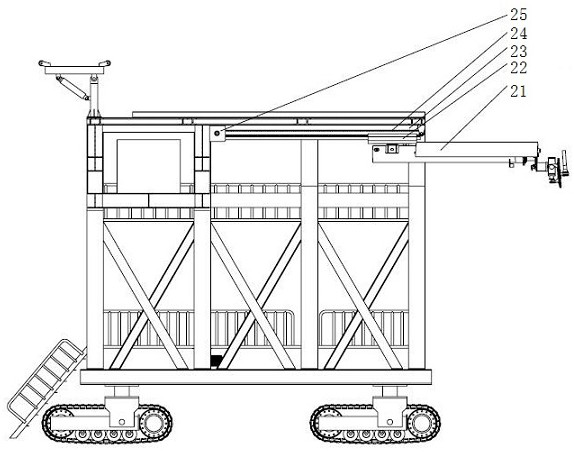

[0040] Embodiment 1: as Figure 1~Figure 5 As shown, a multi-functional working platform suitable for tunnel construction according to the present invention includes a mobile gantry 1, and the mobile gantry system is the main load-bearing part of the working platform. The mobile gantry 1 includes a door frame 11, and the door frame 11 includes pillar supports on both sides, beam supports on the top, and a roof laid on the beam supports, and a channel is formed at the bottom of the door frame 11, which can pass through the cantilever roadheader; The working platform saves the construction space, not only facilitates the passage of construction personnel and other equipment, but also facilitates the transportation of construction materials; the mobile gantry 1 is equipped with a concrete spraying device 2, a bolter device 3 and a steel arch assembly device , the concrete spraying device 2 is used to spray concrete to the tunnel wall for preliminary support, the bolter device 3 i...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, the steel arch assembling device includes a hoisting mechanism 4 for hoisting the steel arch, a transport mechanism 5 for transporting the steel arch, and a splicing mechanism 6 for splicing the steel arch. The hoisting mechanism 4 cooperates with the transport mechanism 5 to transport Mechanism 5 cooperates with splicing mechanism 6. Lift the steel arch frame on the ground to the top of the mobile gantry 1 through the lifting mechanism 4, then move the lifted steel arch frame to the position corresponding to the splicing mechanism 6 through the transportation mechanism 5, and then move the steel arch through the splicing mechanism 6 The frame is spliced, which is convenient for the support installation of the steel arch frame, and improves the support efficiency and quality.

[0043] Further, as figure 2 As shown, the hoisting mechanism 4 includes a lifting hoist 41 and a boom 42, the boom 42 is connected to the top rear end of th...

Embodiment 3

[0046] Embodiment 3: as figure 1 As shown, the splicing mechanism 6 includes an arc-shaped groove rail 61, a splicing winch 62 and a grasping robot 63, the arc shape of the arc-shaped groove rail 61 matches the arc shape of the steel arch, and the arc-shaped groove rail 61 is used for carrying The steel arch also provides rails for the steel arch to slide to both sides. The steel arch frame is transported to the position directly above the arc-shaped groove rail 61 by the transport platform 52, and the steel arch frame is placed on the splicing mechanism 6 through the descent of the lifting support member 53 of the transport mechanism 5, and the steel arch made of I-shaped steel The frame is supported on the outside of the arc groove rail 61 and slides along the arc groove rail 61, which is convenient for grabbing manipulator 63 to grab the steel arch frame; Specifically, the cross section of the arc groove rail 61 is a U-shaped structure, so that the steel wire rope of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com