High-speed train vase pier body maintenance and modification multifunctional working platform

A working platform, multi-functional technology, applied in bridge maintenance, erection/assembly of bridges, bridge reinforcement, etc., can solve problems such as inconvenience of comprehensive maintenance of pier bodies and inability to spray water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

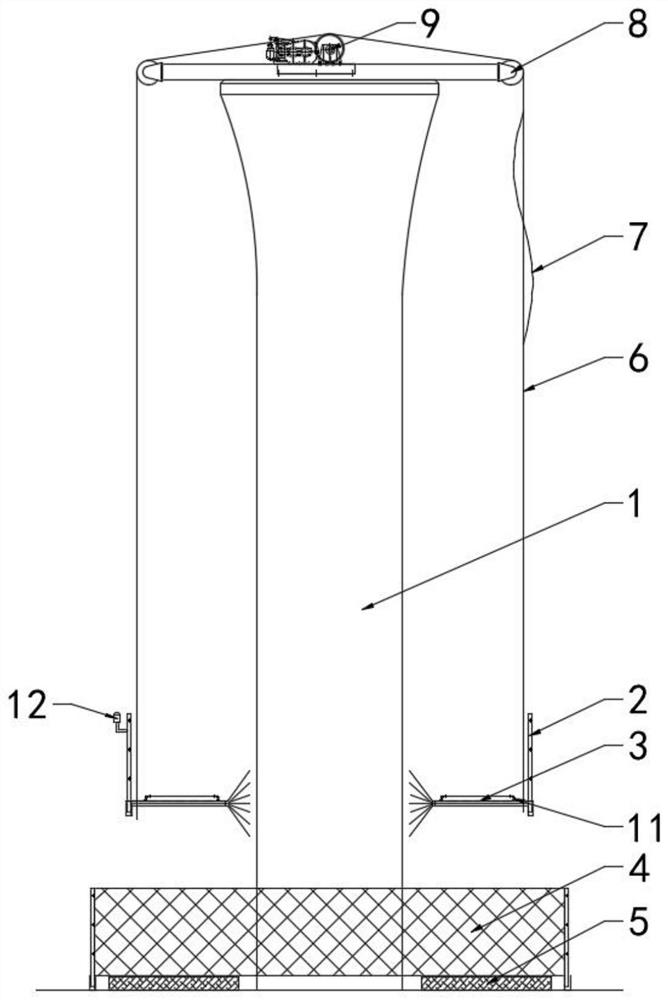

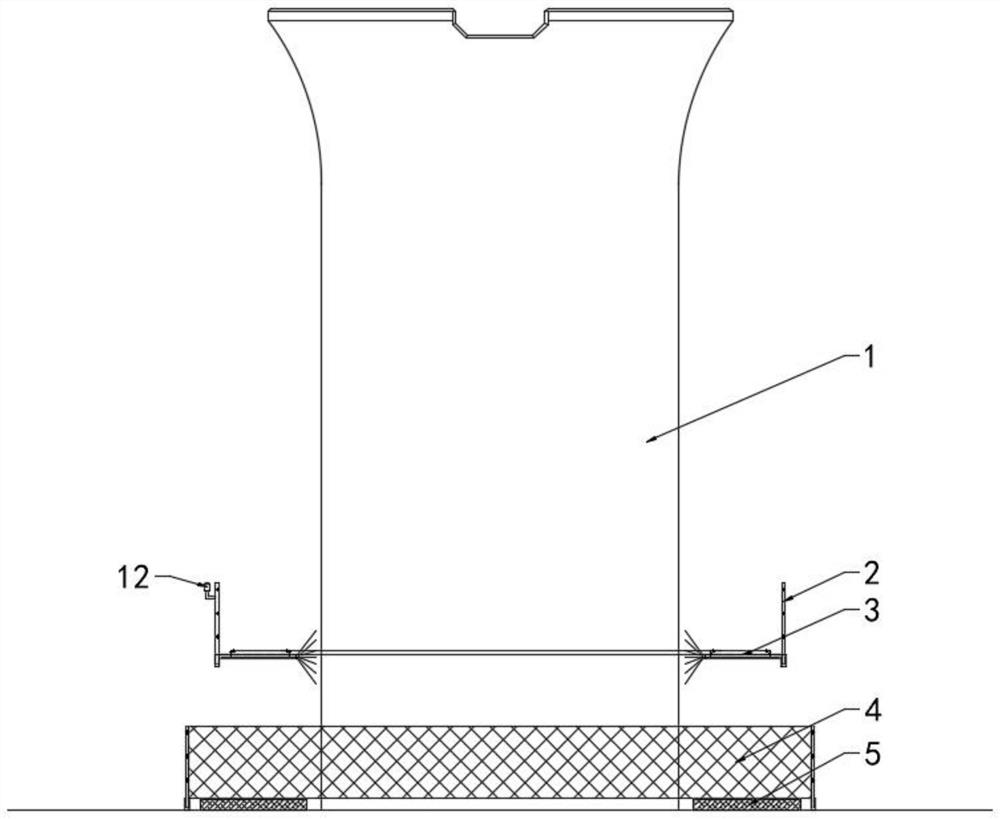

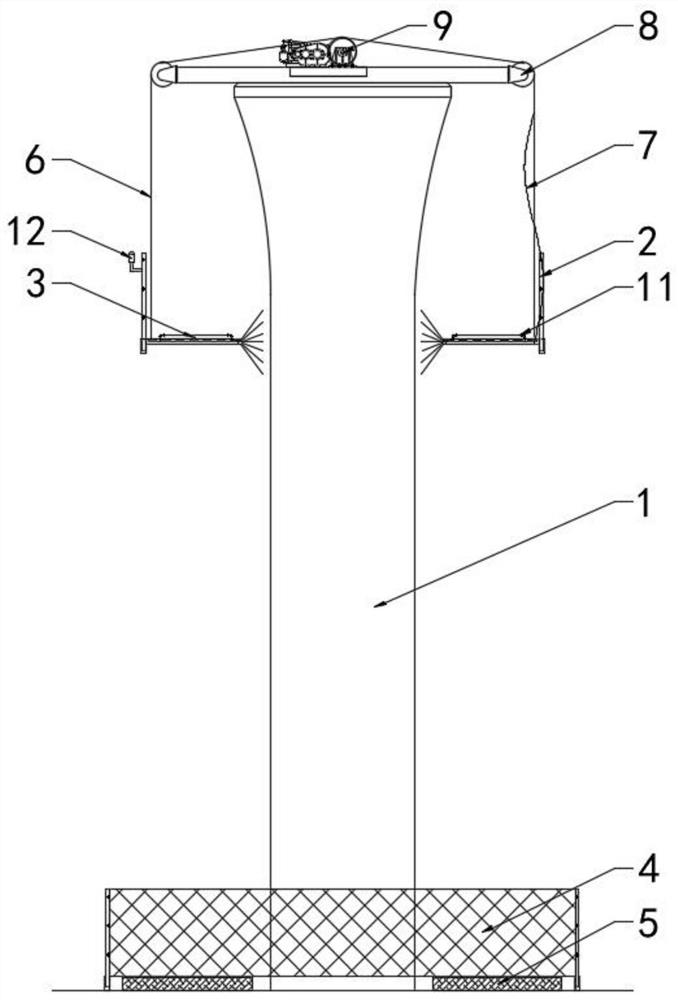

[0040] see Figure 1-7 , the present invention provides a technical solution: a high-speed iron vase pier body maintenance and modification multifunctional working platform, including a pier body body 1, a working platform 3 is socketed on the outside of the pier body body 1, and a plurality of ten thousand is installed inside the working platform 3 To the nozzle 29, a circle of guardrail 2 is fixedly connected to the outside of the working platform 3, rollers 8 are installed on both sides of the top of the pier body 1, and a worm gear reducer 9 is installed on the top of the pier body 1, and the worm gear reducer 9 is transmission connected with Four first wire ropes 6 wound around the roller 8 and tightened, the free ends of the first wire ropes 6 are fixedly connected to the working platform 3, and pressure sensors 11 are installed at their joints, and an alarm indicator light is installed on the outside of the guardrail 2 12. The pressure sensor 11 controls the alarm indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com