Steel bridge deck high-ductility cement-based composite material paving structure and construction method

A composite material and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as high brittleness, poor fatigue resistance, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

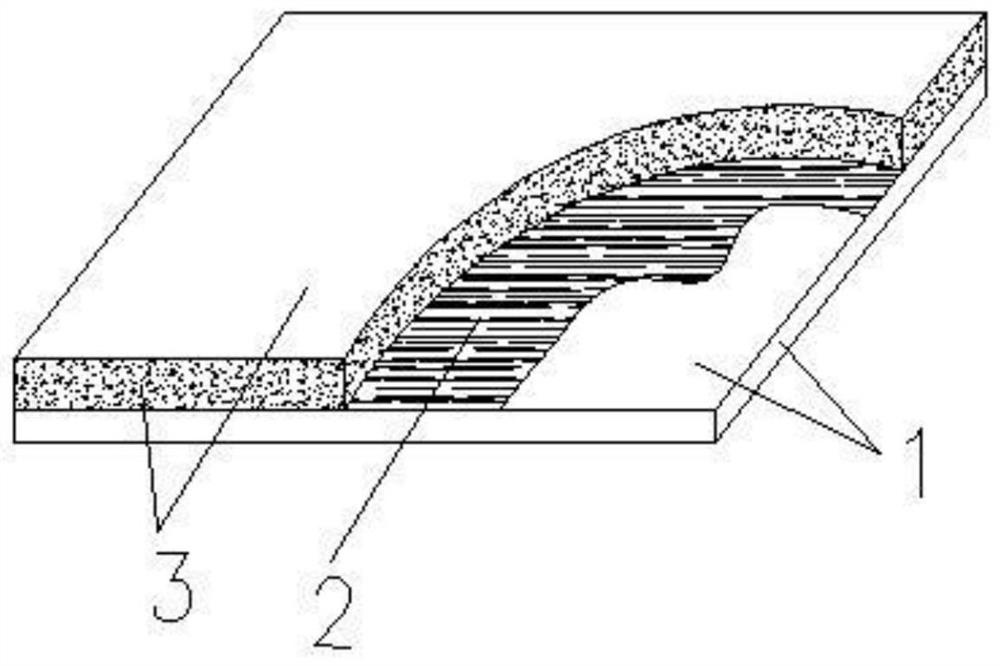

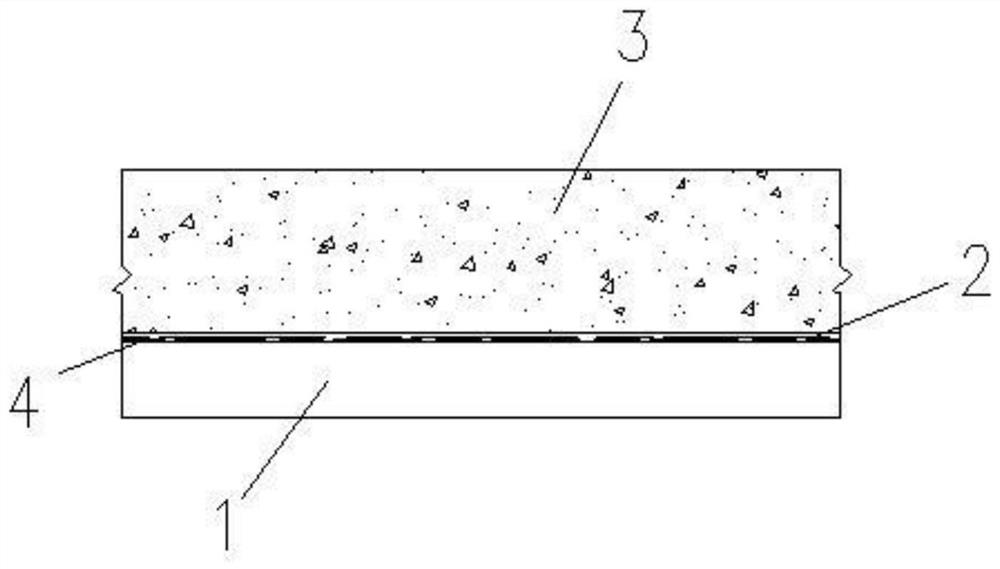

[0031] A steel bridge deck high-ductility cement-based composite material pavement structure, including a high-ductility cement-based composite material pavement layer 3 and an adhesive layer 2, the bottom of the high-ductility cement-based composite material pavement layer 3 passes through the adhesive layer 2 connected with the upper surface of the steel bridge deck layer 1;

[0032] The adhesive layer 2 is a water-based epoxy resin adhesive;

[0033] The thickness of the adhesive layer 2 is 1-1.5mm;

[0034] The high-ductility cement-based composite material pavement layer 3 is formed by on-site pouring of high-ductility cement-based composite materials;

[0035] The high-ductility cement-based composite material includes the following components: P.O 42.5 cement, PVA fiber, fly ash, 70-140 mesh quartz sand, and high-efficiency water reducer; the mass of each component in 1 cubic meter is: cement 235kg, powder Coal ash 940kg, water 352.5kg, quartz sand 423kg, PVA fiber 26...

Embodiment 2

[0038] A construction method for a steel bridge deck high ductility cement-based composite material pavement structure, comprising:

[0039] Step 1. Clean the steel bridge deck, blast and derust the steel bridge deck and spray epoxy zinc-rich paint to form an anti-rust layer 4;

[0040] Step 2. Apply water-based epoxy resin adhesive, and keep the thickness of the adhesive at 1-1.5mm;

[0041] Step 3, paving the high-ductility cement-based composite material;

[0042] Step 4. After the high-ductility cement-based composite material is paved, it is wet-cured, covered with geotextiles and plastic films for curing, and the curing time is at least 7 days.

Embodiment 3

[0044] Described step 3 comprises following construction steps:

[0045] 3.1. High-ductility cement-based composite materials are produced by factory mixing and can be used only after passing the inspection;

[0046] 3.2. Pour the high-ductility cement-based composite material into the paving equipment and spread it evenly on the adhesive layer. The thickness of the high-ductility cement-based composite material paving is controlled at 5-6cm. On the surface of high-ductility cement-based composite materials, during the vibration compaction process, the vibration test piece should not exceed 20s to prevent excessive vibration from causing fiber agglomeration or matrix bleeding;

[0047] 3.3. Use a screed to smooth the surface, and complete the plastering of the high-ductility cement-based composite pavement layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com