Rare earth nano high-strength titanium and preparation method thereof

A nano and high-strength technology, applied in the field of material processing, can solve the problems of reduced material performance, high equipment and tooling requirements, and high volume content of nanocrystals that are easy to recover and grow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the rare earth nano-high-strength titanium according to the embodiment of the present invention includes the following steps:

[0027] a. Vacuum smelting: adding yttrium to pure titanium for vacuum smelting, followed by heating and heat preservation;

[0028] b, primary forging: the ingot obtained in step a is subjected to primary forging;

[0029] c. Secondary forging: performing secondary forging on the ingot obtained in step b;

[0030] d. Heat-treating the cast ingot obtained in step c to obtain rare earth nanometer high-strength titanium.

[0031] According to the preparation method of rare earth nano high-strength titanium according to the embodiment of the present invention, 1. By adding a trace amount of rare earth yttrium element, the pure titanium is effectively purified in the smelting stage, and at the same time, the yttrium element forms a yttrium solid solution or a yttrium-containing phase in the matrix; On the one hand, the pu...

Embodiment 1

[0040] The rare earth element Y is effectively added to the pure titanium, and the Y accounts for 0.01wt% of the total mass. It is smelted in a vacuum consumable electric arc furnace, and then kept at 500° C. for 5 hours. Carry out one forging: the ingot is heated to 925°C, held for 3 hours, then out of the furnace for forging, two times of fire to complete the reversing, three upsetting and three pulling, and the unidirectional deformation of each fire is 51%, and the one time ingot is obtained. Secondary forging is carried out, the primary ingot is kept at 750°C for 0.5 hours, and the reversing six-pier and six-drawing forging is completed in 2 fires. The unidirectional deformation of each fire is 70%, and the secondary ingot is obtained. After the secondary ingot is cooled, it is annealed at 500° C. for 0.5 hour to obtain a rare earth nanometer high-strength titanium material.

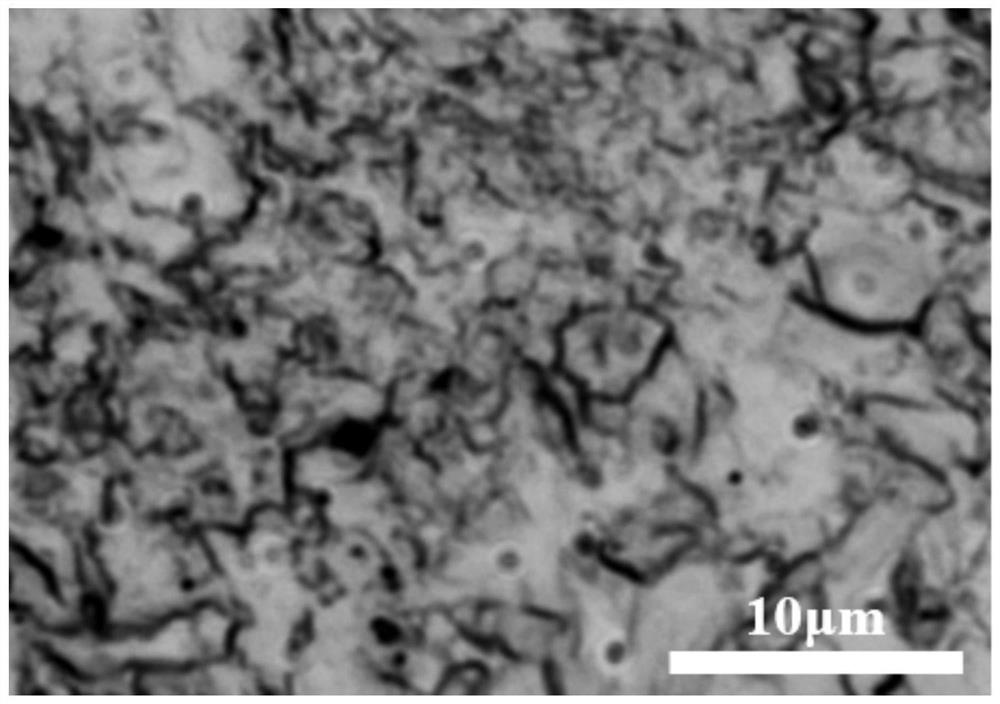

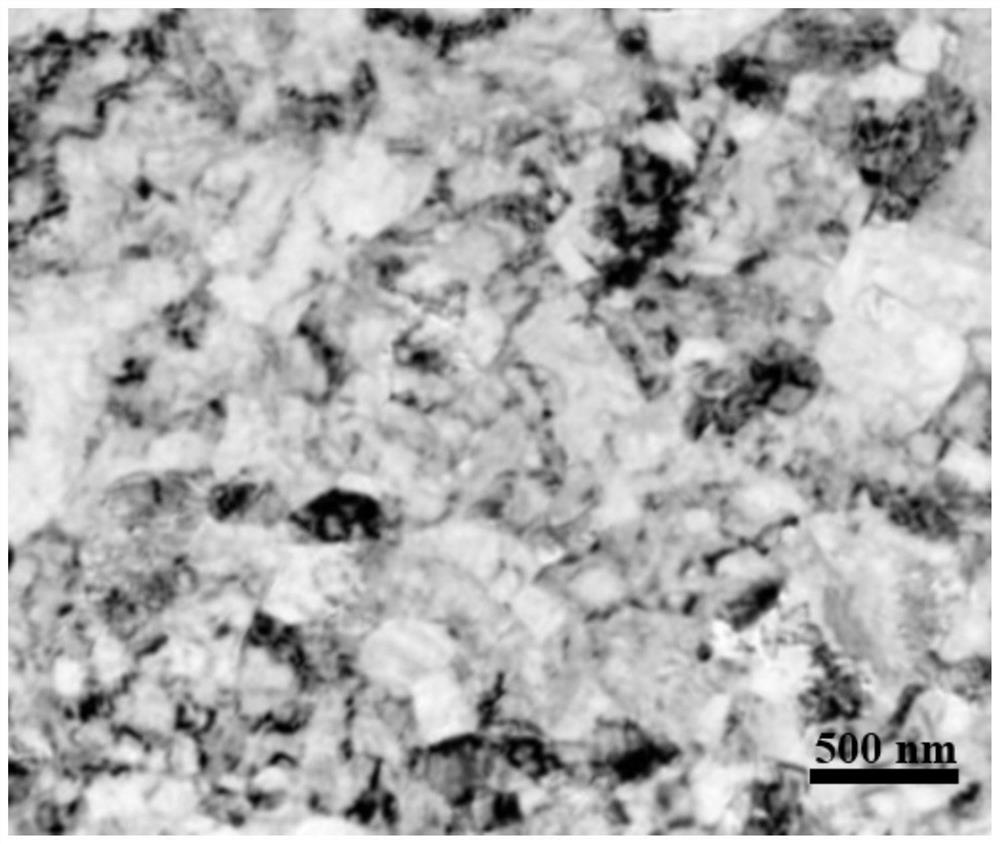

[0041] Such as figure 1 Shown is the metallographic diagram of the ultra-fine-grained pure tita...

Embodiment 2

[0044] The rare earth element Y is effectively added to the pure titanium, and the Y accounts for 0.01wt% of the total mass. It is smelted in a vacuum consumable electric arc furnace, and then kept at 500° C. for 5 hours. Carry out a forging: the ingot is heated to 950°C, held for 1 hour, then out of the furnace for forging, and the reversing, three upsetting and three pulling are completed in one fire, and the unidirectional deformation is 60% per fire, and an ingot is obtained. Secondary forging is carried out, the primary ingot is kept at 750°C for 0.5 hours, and the reversing, six-pier and six-drawing forging is completed in 2 fires, and the unidirectional deformation is 50% per fire to obtain the secondary ingot. After the secondary ingot is cooled, it is annealed at 200°C for 20 hours. A rare-earth nanometer high-strength titanium material is obtained.

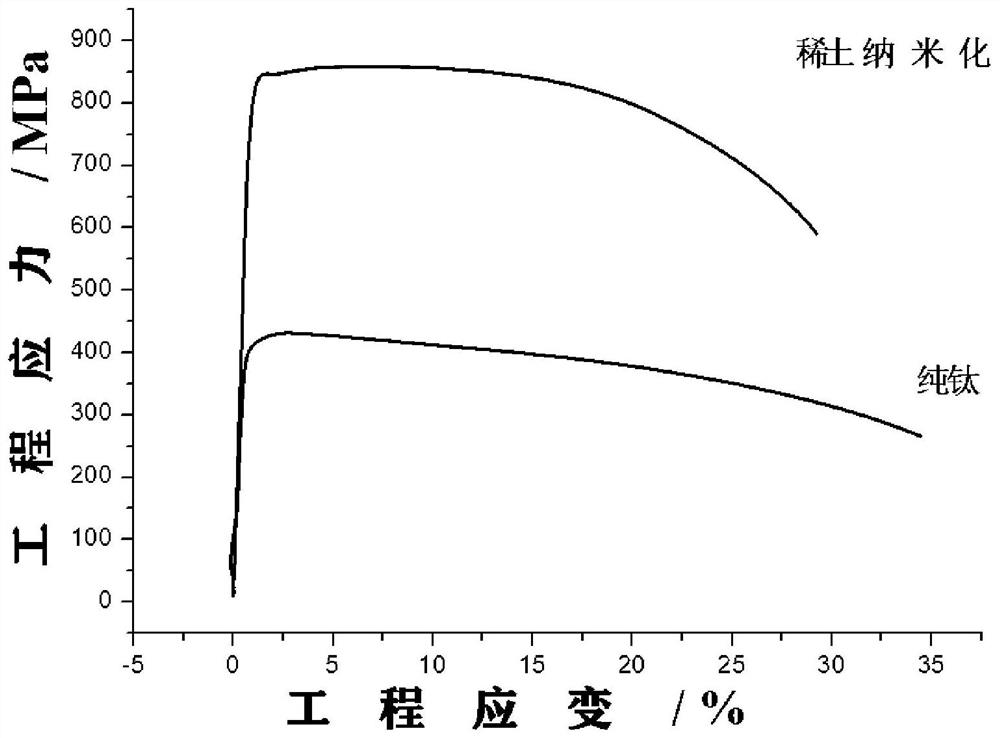

[0045] In the embodiment of the present invention, the tensile strength of titanium at room temperature is 700 MPa af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com