A long-life dsa electrode preparation method that can be used for frequent inversion of cathode and anode

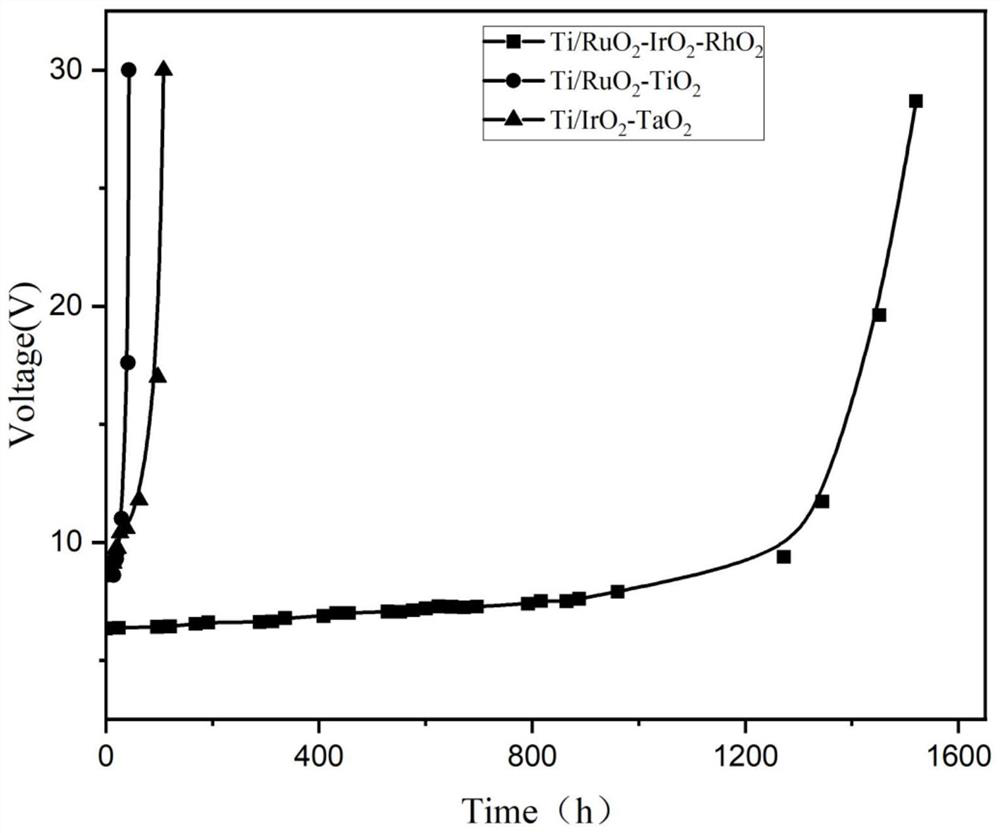

A technology that reverses the anode and cathode, and has a long life. It is applied in the field of electrochemistry, which can solve the problems of insufficient stability of inverted poles and achieve the effect of frequent replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

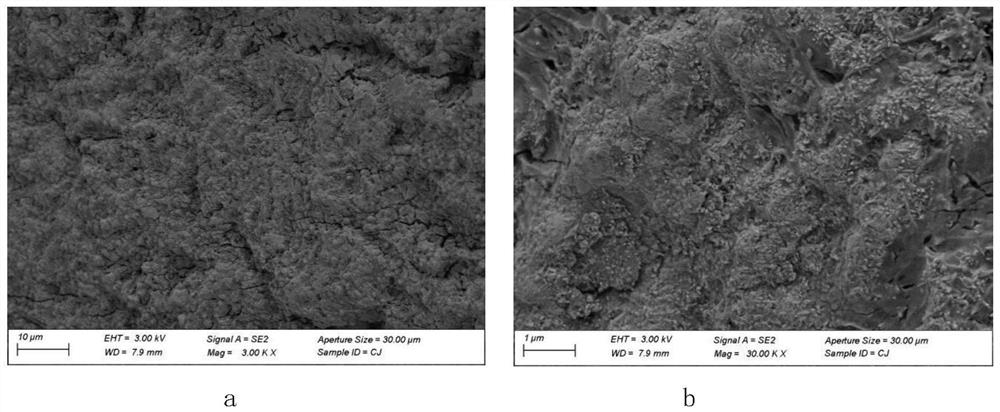

[0031] 1. Cut the industrial titanium tensile mesh into a sample of 2cm×3cm.

[0032] 2. After degreasing, sandblasting, etching with 37% boiled concentrated hydrochloric acid for 2 minutes, ultrasonic washing with deionized water, and drying, a titanium substrate with a clean and rough surface was obtained.

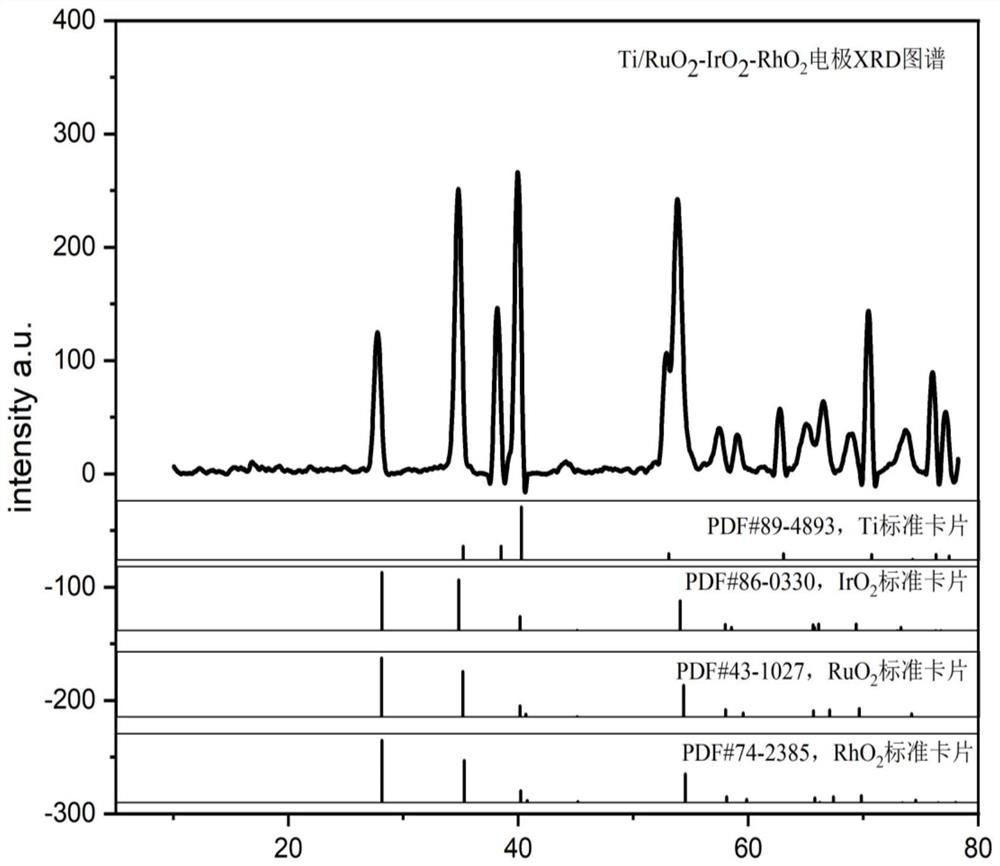

[0033] 3. To prepare the coating solution, dissolve 1g of ruthenium chloride trihydrate, 1g of chloroiridic acid, and 260mg of rhodium chloride in 19ml, 10ml, and 4ml of a mixed solution of concentrated hydrochloric acid and isopropanol at a volume ratio of 1:1.

[0034] 4. According to the volume ratio of 2:1:2, take the three solutions and mix them evenly to get the spare coating solution.

[0035] 5. Apply the coating liquid evenly on both sides of the treated titanium mesh substrate. After coating, transfer to an oven for drying at 70°C for 5 minutes, then transfer to a muffle furnace for thermal decomposition at 400°C for 5 minutes, and cool to room temperature.

...

Embodiment 2

[0038] 1. Cut the industrial titanium tensile mesh into 2cm*3cm samples.

[0039] 2. After degreasing, sandblasting, etching with 37% boiled concentrated hydrochloric acid for 2 minutes, ultrasonic cleaning with deionized water, and drying, the cut titanium mesh was cleaned to obtain a titanium substrate with a rough surface.

[0040] 3. To configure the coating solution, dissolve 1g of ruthenium chloride trihydrate, 1g of chloroiridic acid, and 300mg of manganese chloride in 20ml, 10ml, and 10ml of the mixed solution of concentrated hydrochloric acid and isopropanol at a volume ratio of 1:2, according to 3 : The volume ratio of 1:1 takes three kinds of solutions and mixes them evenly to get the spare coating solution.

[0041] 4. Apply the coating solution evenly on both sides of the treated titanium mesh substrate. After coating, transfer it to an oven for drying at 80°C for 5 minutes, then transfer it to a box-type resistance furnace for thermal decomposition at 450°C for 5...

Embodiment 3

[0044] 1. Choose a 15cm*39cm titanium plate as the substrate.

[0045] 2. After degreasing, sandblasting, boiling and etching the titanium plate with 20% oxalic acid for 2 hours, ultrasonic washing with deionized water, and drying, a clean and rough titanium substrate was obtained.

[0046] 3. To configure the coating solution, dissolve 15g of tantalum pentachloride, 8g of chloroiridic acid, and 10g of rhodium trichloride in 160ml, 80ml, and 150ml of concentrated hydrochloric acid and isopropanol with a volume ratio of 1:1. : The ratio of 1:2 is to take the three solutions and mix them evenly to get the spare coating solution.

[0047] 4. Apply the coating solution evenly on one side of the treated titanium mesh substrate, transfer it to an oven for drying at 80°C for 5 minutes after coating, then transfer it to a muffle furnace for thermal decomposition at 500°C for 5 minutes, and cool to room temperature.

[0048] Repeat the above step 4 for 20 times, and anneal at 500° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com