Shearing device of shear wall pulling piece and using method

A shearing device and shear wall technology, applied in the field preparation of building components, machine tools suitable for grinding workpiece edges, formwork/formwork/working frame connectors, etc., can solve laborious and stabbing construction workers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

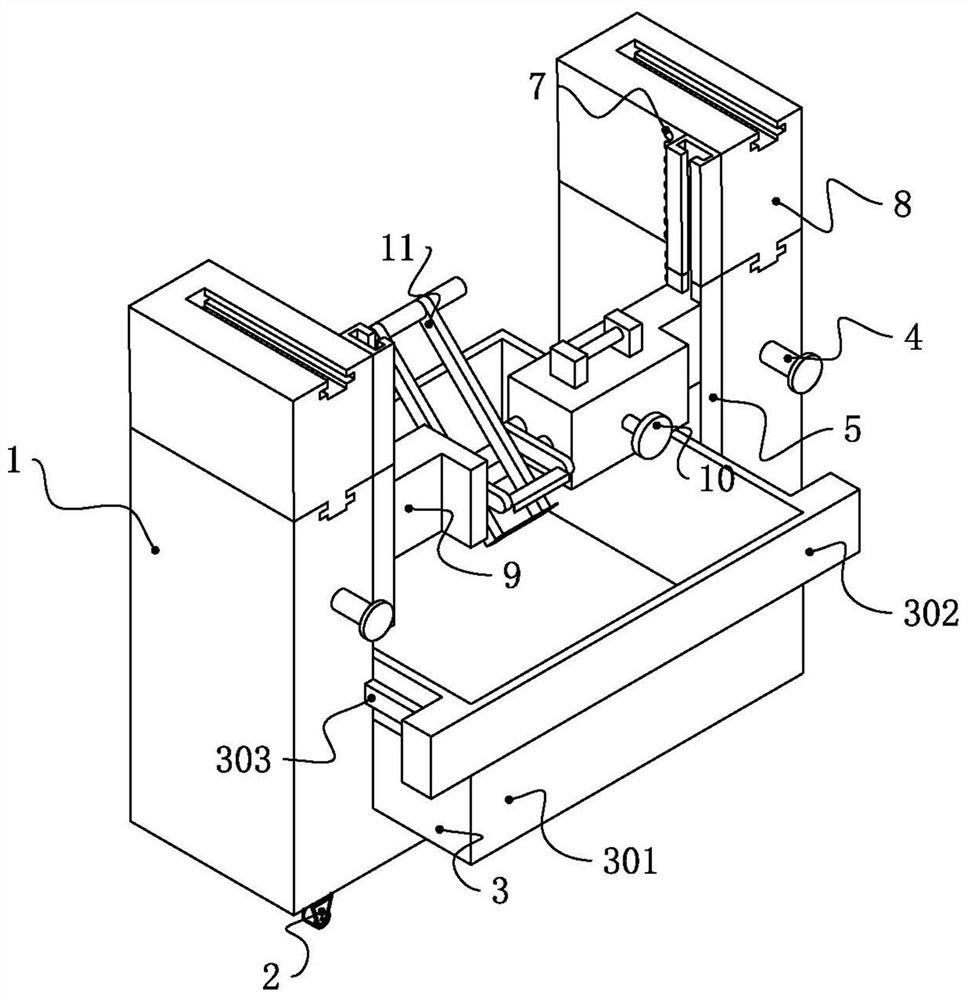

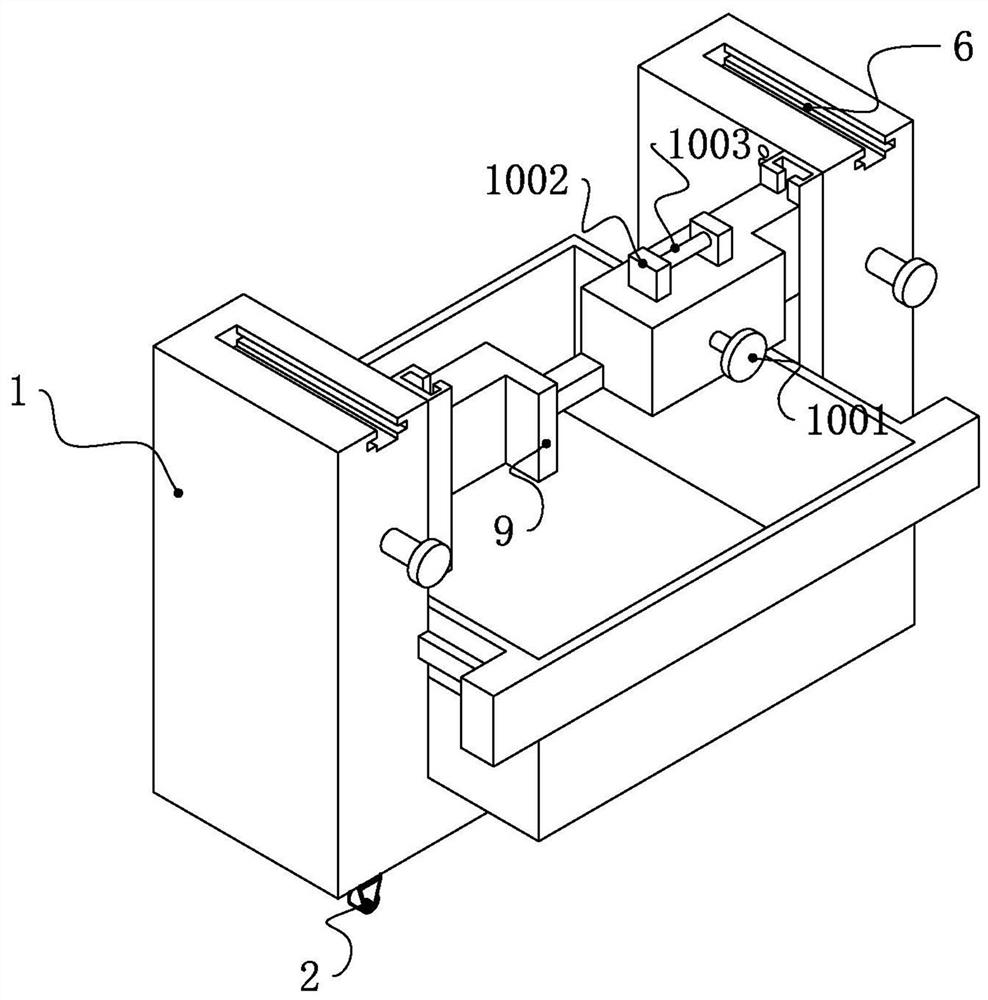

[0018] Embodiment 1, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a shearing device for a shear wall pull piece includes a U-shaped main body 1, universal wheels 2 are fixedly installed at the four corners of the bottom end of the U-shaped main body 1, and the bottom end of the U-shaped mouth of the U-shaped main body 1 is snapped and installed There is a collection mechanism 3, two pressing columns 4 are fixedly installed on the front of the U-shaped main body 1, vertical chute 5 is fixedly installed on the side of the inner wall of the U-shaped main body 1, and a sliding mechanism is engaged and connected between the vertical chute 5 9. The sliding mechanism 9 is provided with a grinding mechanism 10 and a cutting mechanism 11. The two top ends of the U-shaped main body 1 are provided with first transverse grooves 6, and the inner wall of the U-shaped main body 1 is provided on one side of the vertical chute 5. There ar...

Embodiment 2

[0024] Embodiment 2. A method for using a shear wall pull-tab shearing device, comprising the following steps: a. installation of template pull-tab components; b. installation of back corrugated diagonal bracing components; c.

[0025] Among them, the installation of template puller components: upload the templates that have been dismantled and cleaned in the lower layer according to the area and order and place them securely. If stacked, they should be facing upwards, so that the release agent can be applied, and then removed one by one. Molding agent, when the interior wall formwork is installed, it starts from the inner corner (corner) and extends to both sides according to the order of the formwork number. In order to prevent the formwork from falling, temporary fixed diagonal braces (wood, steel pipes, etc.) Apply a suitable release agent to each template, rotate the C slot vertically by 45°, snap it into one side of the pull tab, then rotate it in the opposite direction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com