Amine functionalized activated carbon material as well as preparation method and application thereof

An activated carbon and amine functional technology, which is applied in the field of adsorption and separation of carbonyl sulfide gas, can solve the problems of high cost, complicated preparation process, and difficult industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of amine functionalized activated carbon material, comprising the following steps:

[0026] 1) First, wash the granular activated carbon (ie, blue carbon, with a particle size of 0.5~1.0 cm) with deionized water until the pH is neutral;

[0027] 2) Mix 2 mL of N-[3-(trimethoxysilyl)propyl]ethylenediamine with 20 mL of deionized water, sonicate for 6 min, then add 10 g of activated carbon washed in step 1), and Reflux and stir at 80°C for 4 h, and finally vacuum-dry at 60°C for 10 h (the vacuum drying pressure is -0.08MPa), and the amine-functionalized activated carbon material is obtained.

Embodiment 2

[0029] A preparation method of amine functionalized activated carbon material, comprising the following steps:

[0030] 1) First, wash the granular activated carbon (ie, blue carbon, with a particle size of 0.5~1.0 cm) with deionized water until the pH is neutral;

[0031] 2) Mix 4 mL of N-[3-(trimethoxysilyl)propyl]ethylenediamine with 20 mL of deionized water, sonicate for 8 min, then add 10 g of activated carbon washed in step 1), and Reflux and stir at 80°C for 6 h, and finally vacuum-dry at 60°C for 10 h (the vacuum drying pressure is -0.08MPa), and the amine-functionalized activated carbon material is obtained.

Embodiment 3

[0033] A preparation method of amine functionalized activated carbon material, comprising the following steps:

[0034] 1) First, wash the granular activated carbon (ie, blue carbon, with a particle size of 0.5~1.0 cm) with deionized water until the pH is neutral;

[0035] 2) Mix 8 mL of N-[3-(trimethoxysilyl)propyl]ethylenediamine with 20 mL of deionized water, sonicate for 10 min, and then add 10 g of activated carbon washed in step 1), Reflux and stir at 80°C for 8 h, and finally vacuum-dry at 60°C for 10 h (the vacuum drying pressure is -0.08MPa) to obtain the amine-functionalized activated carbon material.

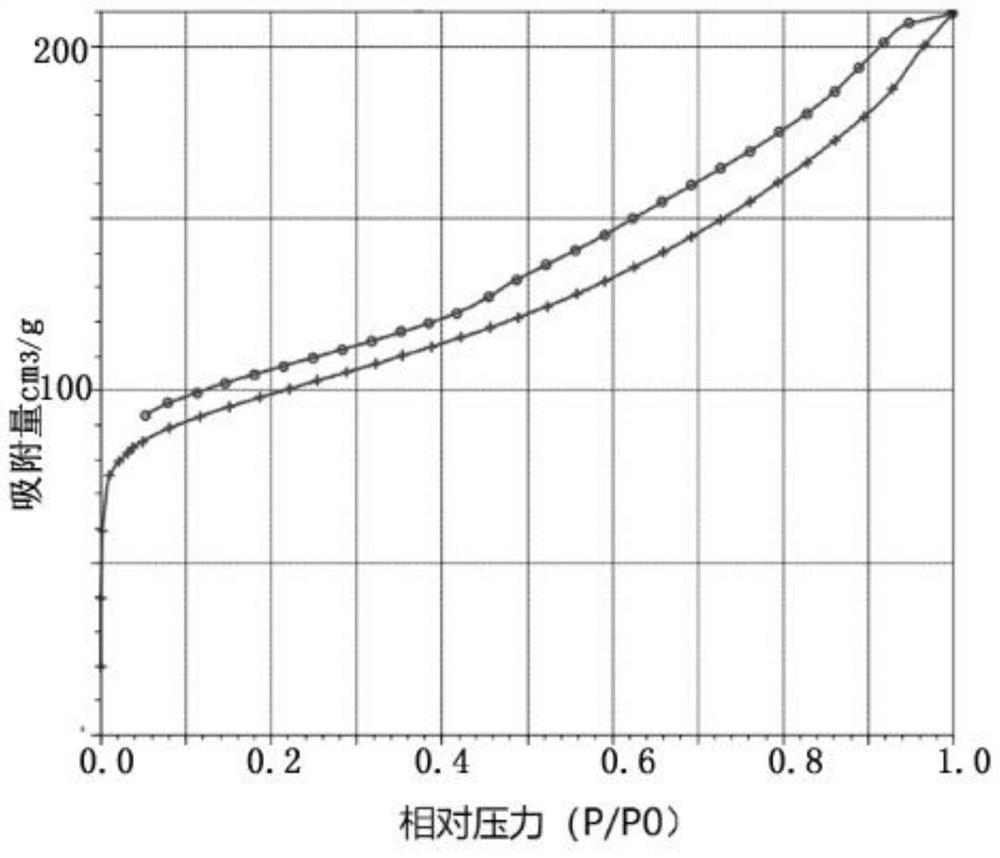

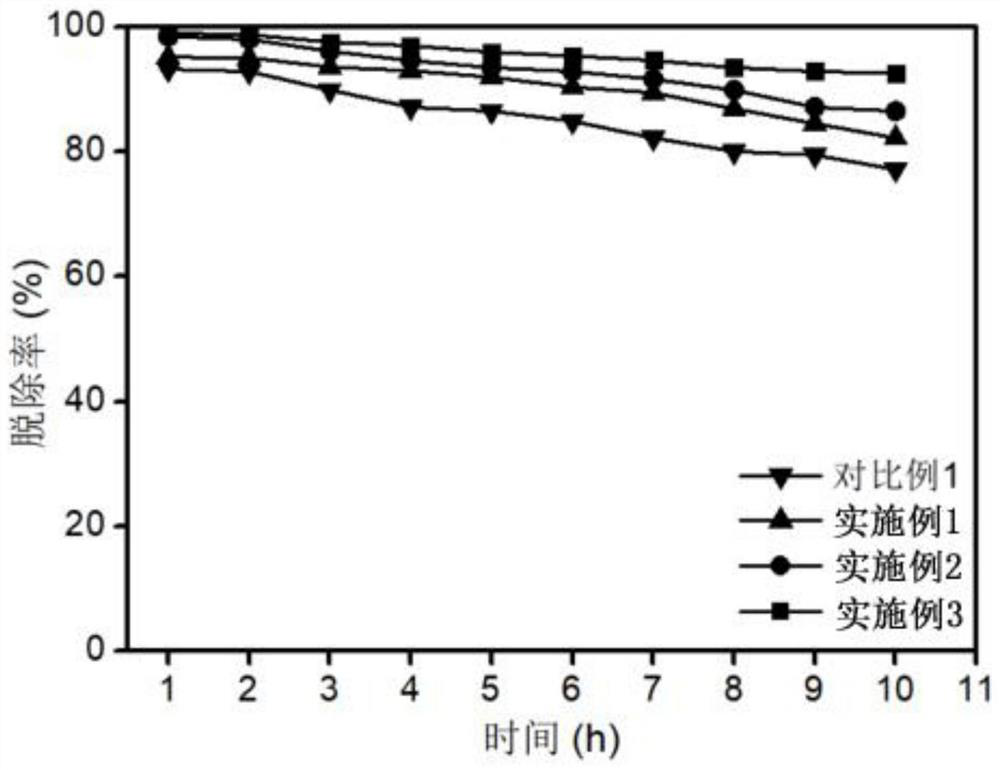

[0036] The activated carbon raw material used in step 1) of Example 3 of the present invention and the final adsorbent material were subjected to BET characterization respectively, and the specific surface area of the activated carbon raw material was 435.45 m 2 / g, the specific surface area of the final adsorbent material is 358.31m 2 / g. The amine functionali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com