Box-type moving bed waste gas purification system

An exhaust gas purification system and moving bed technology, applied in gas treatment, chemical instruments and methods, and separation of dispersed particles, can solve problems such as poor resistance to impact load variability, low regeneration efficiency of regeneration technology, and unstable emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

[0037] This proposal proposes a box-type moving bed exhaust gas purification system, which is described in detail as follows.

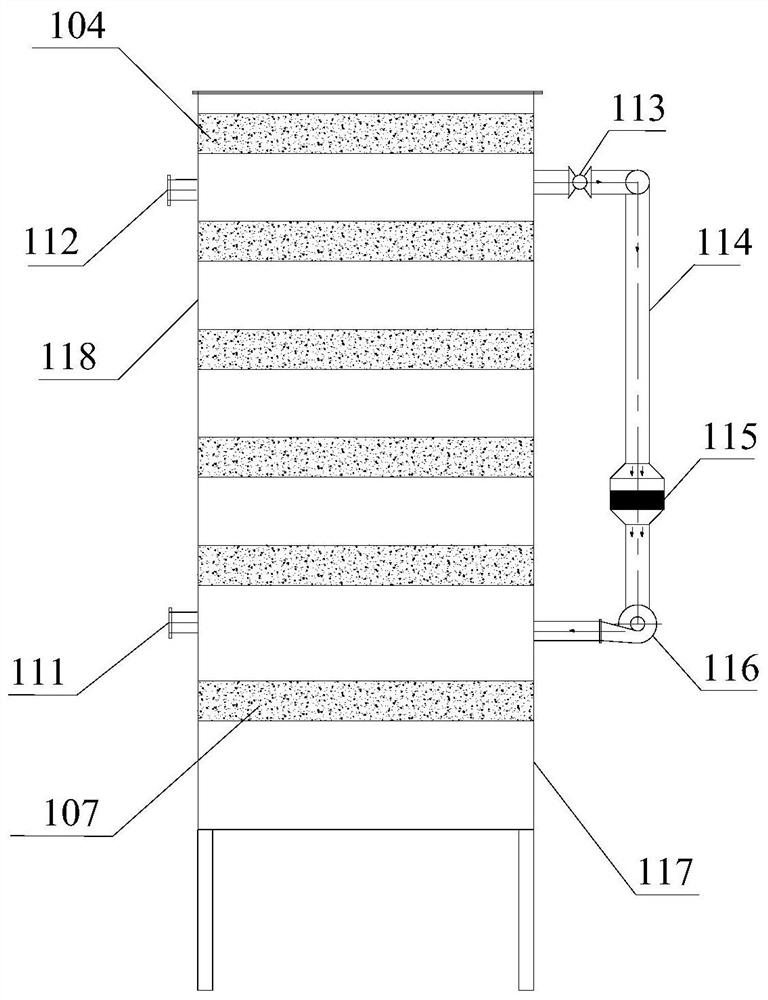

[0038] figure 1 A schematic block diagram of a box-type moving bed exhaust gas purification system provided in an embodiment of the present invention, as shown in figure 1 As shown, the adsorption purification unit 100 and the regenerative cooling unit 200 .

[0039] Wherein, the adsorption purification unit 100 is provided with multiple l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com