Mixed membrane for all-vanadium redox flow battery, preparation method and application

An all-vanadium redox flow battery and composite membrane technology, applied in fuel cells, regenerative fuel cells, circuits, etc., to achieve the effects of improving proton transfer rate, optimizing vanadium resistance performance, and optimizing proton transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 MOF-801 and MOF-808

[0045] Synthesis of MOF-801: 16g ZrOCl 2 ·8H 2 Add O and 5.8g fumaric acid to a 500mL screw cap bottle, then add 270mL 20:7 (v / v) DMF / formic acid mixed solution, add and mix well, heat the mixture at 130°C for 6 hours, cool to After room temperature, the white precipitate was collected by centrifugation, and washed more than 3 times with excess DMF to remove impurities, then, the precipitate was washed with deionized water 3 times a day for 3 days, and then washed with acetone again, after that, at room temperature Drying for 24 h, followed by vacuum drying at 150 °C for 24 h to obtain the activated MOF powder.

[0046] Synthesis of MOF-808: 4.85g ZrOCl 2 ·8H 2 O and 1.05g of trimesic acid were added to a 500mL screw cap bottle, then 450mL of 1:1 (v / v) DMF / formic acid mixed solution was added, added and mixed well. The mixture was heated at 130 °C for 48 h, and after cooling to room temperature, the white precip...

Embodiment 2

[0047] Example 2 Preparation of SPEEK / MOF hybrid membrane

[0048] SPEEK was prepared by sulfonating PEEK in sulfuric acid (98wt.%) at 50°C for 5h. Then SPEEK / MOF hybrid membranes were prepared by the following method.

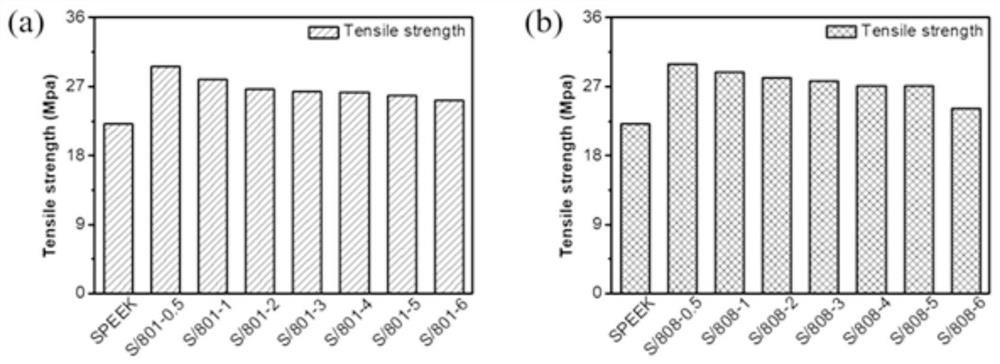

[0049] A certain amount of MOF was dispersed in 5 mL of DMF by sonication. Then 5 mL of SPEEK / DMF solution (0.15 g / mL) was added to the MOF / DMF mixture, and the new mixture was sonicated for 2 hours, followed by stirring and mixing for 24 hours to form a homogeneous MOF / SPEEK mixture. Precisely control the loading amount of MOF (0-6%), and the actual film thickness is shown in Table 1 (50±2μm). The corresponding hybrid film is denoted as S / X-Y, where S is SPEEK, X represents the MOF type (for example, 801 is MOF-801, 808 is MOF-808), and Y is the mass ratio of MOF and SPEEK. Films were prepared by solution casting, then dried in an oven at 60 °C for 6 h, and then further dried in a vacuum oven at 100 °C for 12 h. After stripping from the glass plate, pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com