High-insulativity safety rectifier transformer and working method thereof

A rectifier transformer and high insulation technology, which is applied in transformers and fields, can solve the problems of poor heat dissipation efficiency, weak heat resistance of transformers, and affecting service life, etc., and achieve the effect of increasing protection performance, preventing rain erosion, and strong heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

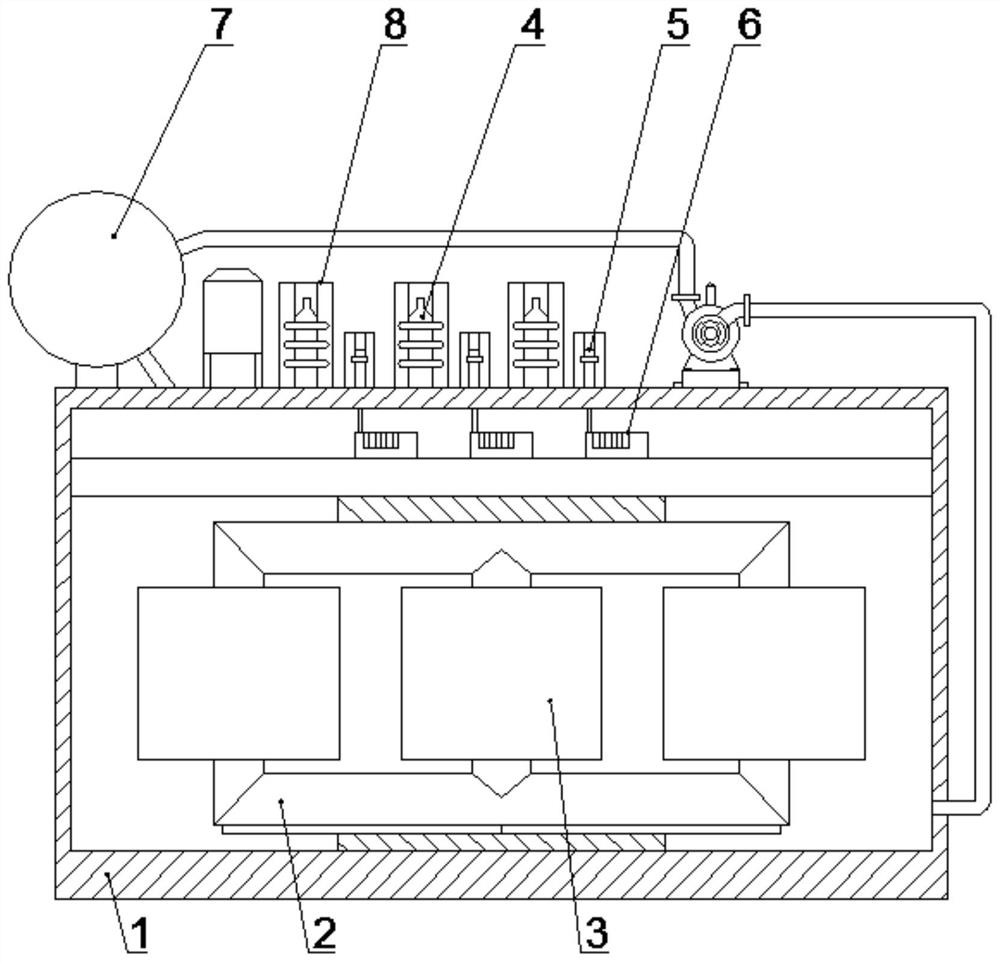

[0037] Such as Figure 1-4 The shown high-insulation safety rectifier transformer includes: casing 1, iron core 2, winding 3, high-voltage connector 4, low-voltage connector 5, rectifier bridge 6, oil conservator 7 and connector protection device 8. The casing 1 is provided with an iron core 2, and the outer side of the iron core 2 is wrapped with windings 3, and the windings 3 are provided in multiples; the top of the casing 1 is provided with a high-voltage joint 4, and the high-voltage joint 4 is connected to Winding, one side of the high-voltage joint 4 is provided with a low-voltage joint 5, and the low-voltage joint 5 is connected with a rectifier bridge 6, and the input end of the rectifier bridge 6 is connected to the winding 3; the outer side of the high-voltage joint 4 is provided with a joint protection device 8 , the outer side of the low pressure joint 5 is provided with a joint protection device 8;

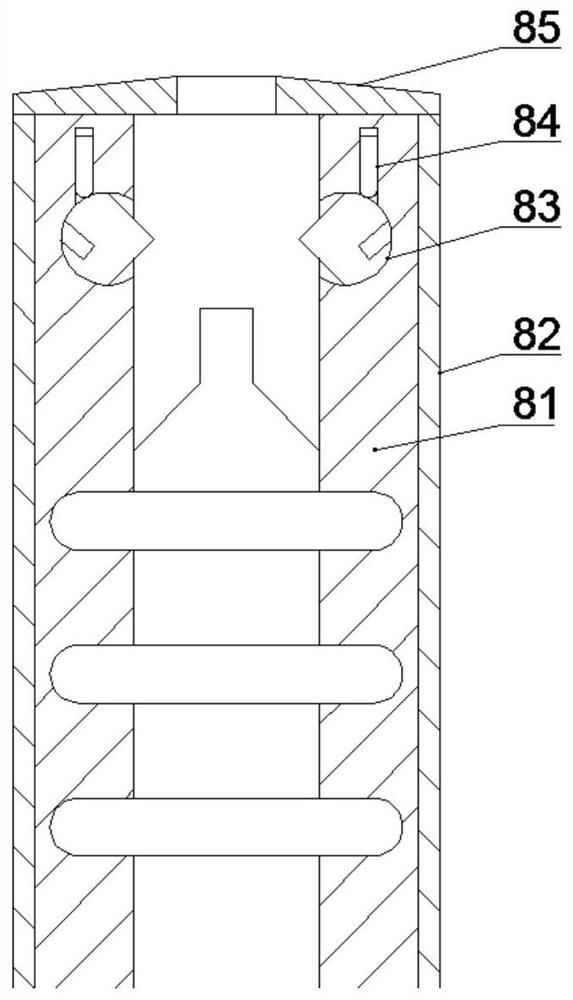

[0038]The joint protection device 8 described in this embodime...

Embodiment 2

[0050] Such as Figure 1-2 The shown high-insulation safety rectifier transformer includes: shell 1, iron core 2, winding 3, high-voltage joint 4, low-voltage joint 5, rectifier bridge 6, oil conservator 7 and joint protection device 8, all The casing 1 is provided with an iron core 2, and the outer side of the iron core 2 is wrapped with windings 3, and the windings 3 are provided in multiples; the top of the casing 1 is provided with a high-voltage joint 4, and the high-voltage joint 4 is connected to Winding, the side of the high-voltage joint 4 is provided with a low-voltage joint 5, and the low-voltage joint 5 is connected with a rectifier bridge 6, and the input end of the rectifier bridge 6 is connected to the winding 3; the outer side of the high-voltage joint 4 is provided with a joint protection device 8 , the outer side of the low pressure joint 5 is provided with a joint protection device 8;

[0051] The joint protection device 8 described in this embodiment inclu...

Embodiment 3

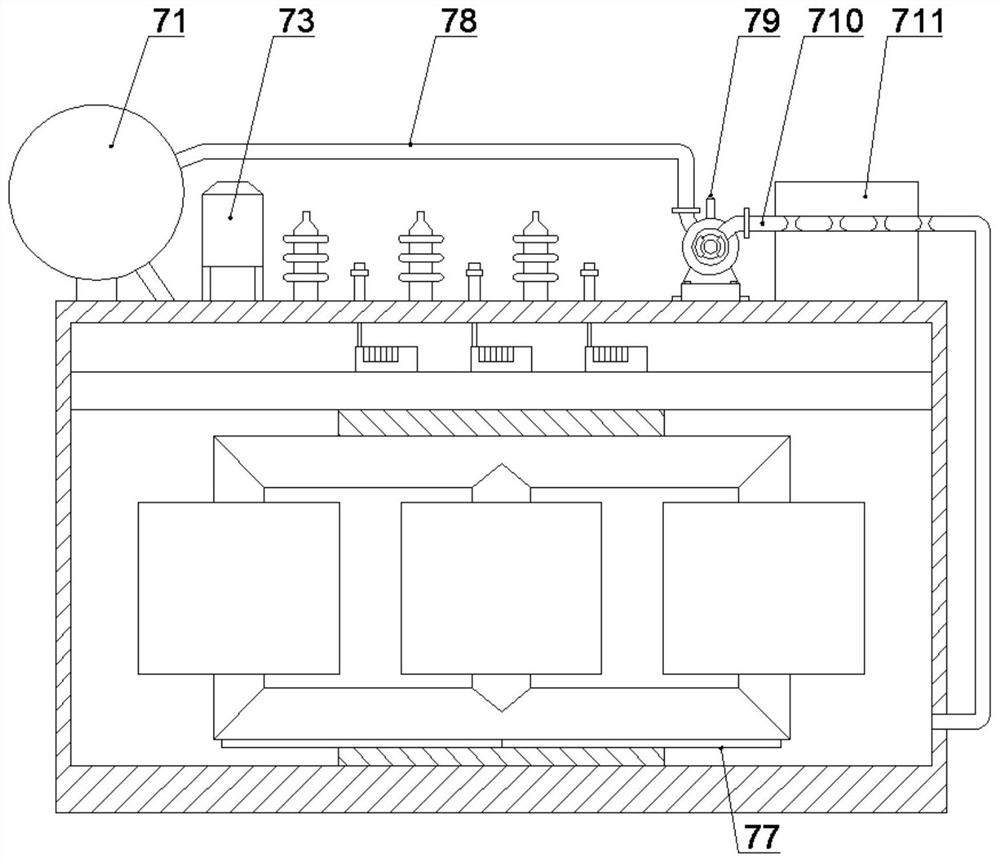

[0054] Such as figure 1 , 3 A high-insulation safety rectifier transformer shown in and 4 includes: a housing 1, an iron core 2, a winding 3, a high-voltage connector 4, a low-voltage connector 5, a rectifier bridge 6, an oil conservator 7 and a connector protection device 8 , the casing 1 is provided with an iron core 2, and the outside of the iron core 2 is wrapped with a winding 3, and a plurality of windings 3 are provided; the top of the casing 1 is provided with a high-voltage joint 4, and the high-voltage joint 4 is connected to the winding, the high-voltage joint 4 is provided with a low-voltage joint 5 on one side, and the low-voltage joint 5 is connected with a rectifier bridge 6, and the input end of the rectifier bridge 6 is connected to the winding 3; the outer side of the high-voltage joint 4 is provided with joint protection device 8 , a joint protection device 8 is provided on the outside of the low-pressure joint 5 ; an oil storage tank 7 is provided on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com