Environment-friendly auxiliary fixing device for goaf grouting and operation method thereof

A technology for fixing devices and goafs, applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve problems such as outflow of grouting material pollution, smoke outflow, waste outflow of grouting material, shaking of grouting pipe, etc. The effect of stable slurry, avoiding waste and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

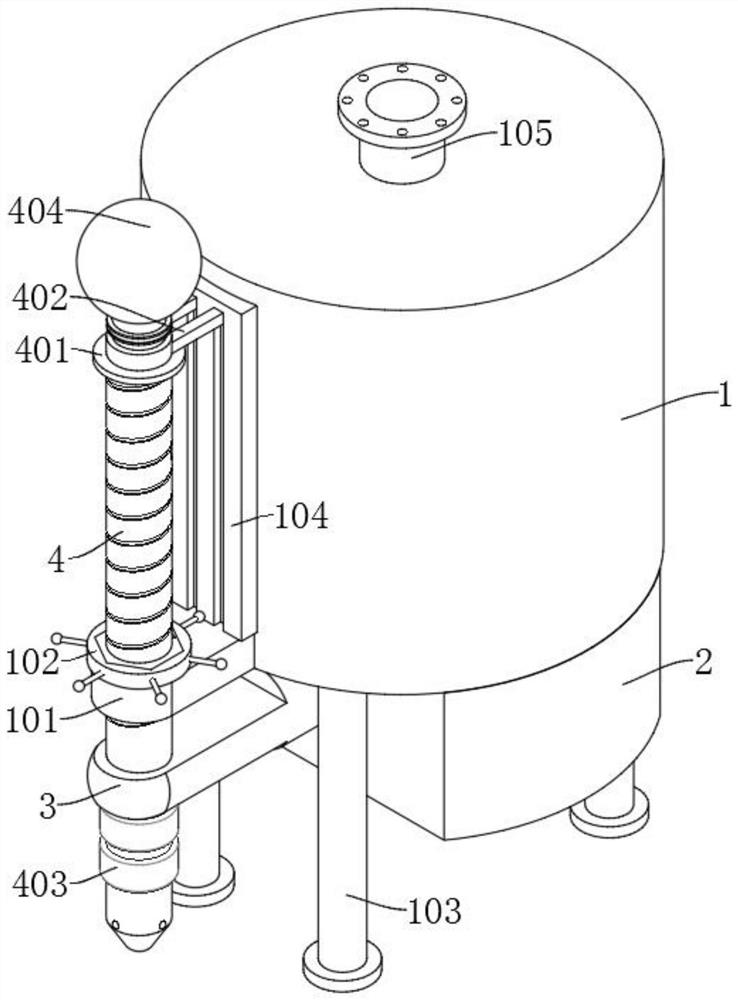

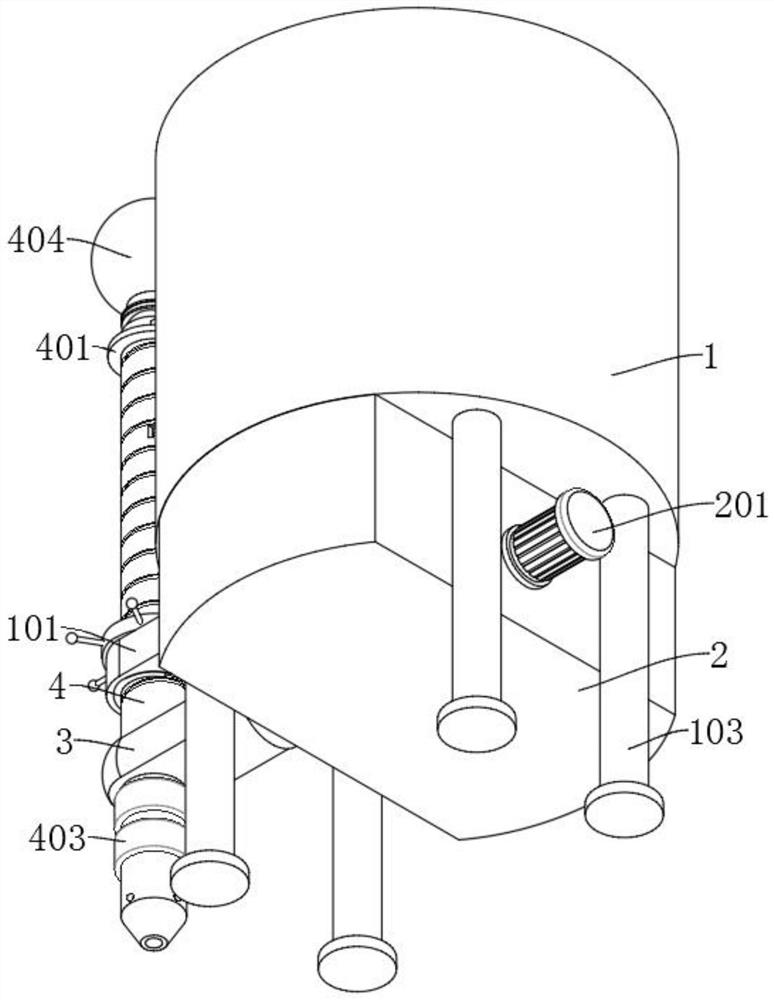

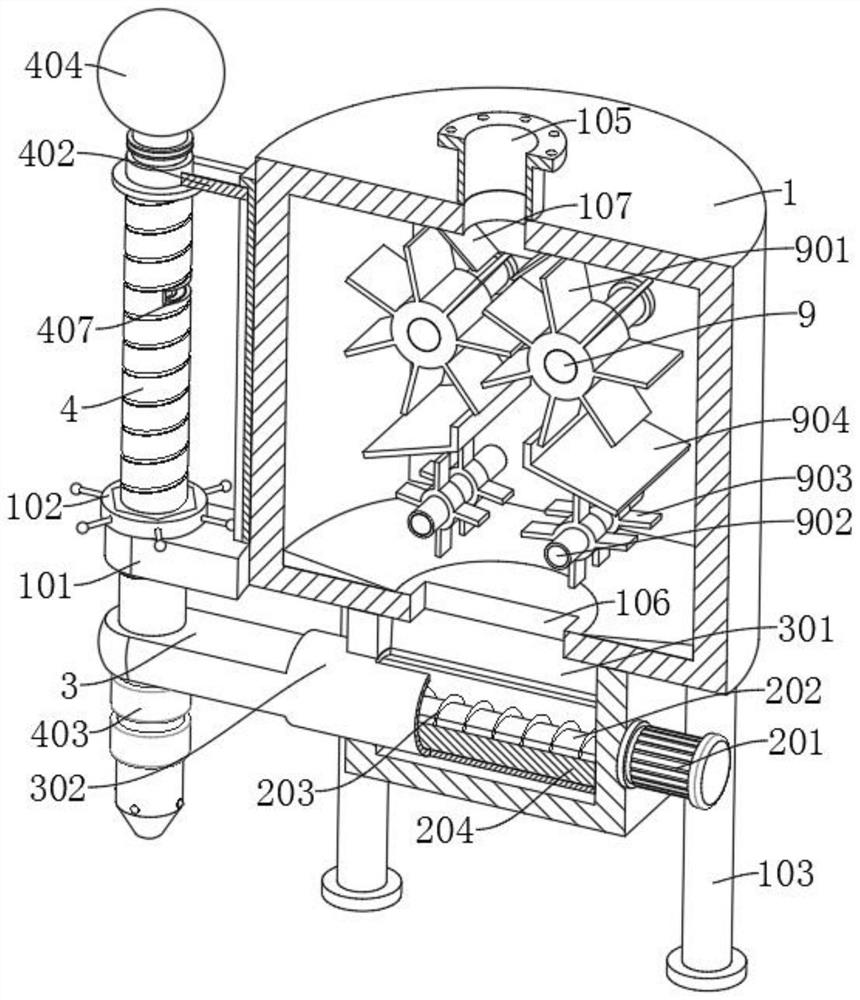

[0041] refer to Figure 1-5 , an environmentally friendly auxiliary fixing device for goaf grouting, including a stirring tank 1 and a conveying tank 2, the conveying tank 2 is fixedly connected to the bottom of the stirring tank 1, and the outer wall of the stirring tank 1 is fixedly connected with a fixed block 101, the fixed block A rotating disk 102 is rotatably connected to the 101, and a grouting pipe 4 is connected with the inner thread of the rotating disk 102;

[0042] An inner pipe 405 is arranged in the grouting pipe 4, the auxiliary parts and the air cylinder assembly 8 are connected with each other in the grouting pipe 4, an air bag 403 is connected to the outer wall of the grouting pipe 4, and the air bag 403 is communicated with the air cylinder assembly 8;

[0043] The grouting pipe 4 is also slidably connected with a pin 502, the conveying tank 2 is connected with a round pipe 302, the outer wall of the round pipe 302 is integrally formed with a square pipe 3,...

Embodiment 2

[0047] refer to Figure 1-7 and Figure 10 , an environmentally friendly auxiliary fixture for goaf grouting, including a stirring tank 1 and a conveying tank 2, the conveying tank 2 is fixedly connected to the bottom of the stirring tank 1, and the stirring tank 1 can stir the grouting material to avoid clogging, The conveying tank 2 can transport the grouting material, which is convenient for work. The outer wall of the mixing tank 1 is fixedly connected with a fixed block 101. The fixed block 101 is rotatably connected with a rotating disk 102, and the rotating disk 102 is internally threaded with a grouting pipe 4. Rotating the disc 102 can make the grouting pipe 4 move downward, making it convenient for work;

[0048] An inner pipe 405 is arranged in the grouting pipe 4, the auxiliary parts and the air cylinder assembly 8 are connected with each other in the grouting pipe 4, an air bag 403 is connected to the outer wall of the grouting pipe 4, and the air bag 403 is comm...

Embodiment 3

[0056] refer to Figure 1-4 and Figure 8-10 , an environmentally friendly auxiliary fixture for goaf grouting, including a stirring tank 1 and a conveying tank 2, the conveying tank 2 is fixedly connected to the bottom of the stirring tank 1, and the stirring tank 1 can stir the grouting material to avoid clogging, The conveying tank 2 can transport the grouting material, which is convenient for work. The outer wall of the mixing tank 1 is fixedly connected with a fixed block 101. The fixed block 101 is rotatably connected with a rotating disk 102, and the rotating disk 102 is internally threaded with a grouting pipe 4. Rotating the disc 102 can make the grouting pipe 4 move downward, making it convenient for work;

[0057] An inner pipe 405 is arranged in the grouting pipe 4, the auxiliary parts and the air cylinder assembly 8 are connected with each other in the grouting pipe 4, an air bag 403 is connected to the outer wall of the grouting pipe 4, and the air bag 403 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com