Efficient and rapid removal of as(iii) or as(v) based on magnetic core-shell bimetallic MOF

A bimetallic and magnetic technology, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as pollution, achieve the effect of overcoming the difficulty of recycling, excellent effect, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of magnetic core-shell bimetallic MOF material

[0030] Add 0.05 g of Fe3O4 nanoparticles into a beaker containing 2 g of polyvinylpyrrolidone and 30 mL of methanol. After sonicating for 30 minutes, 0.98 g of 2-methylimidazole was added to the mixture, which was then sonicated for another 5 minutes. At the same time, 0.7417 g of zinc nitrate hexahydrate and 0.1455 g of cobalt nitrate hexahydrate were weighed and dissolved in 30 mL of methanol. After mixing the two solutions above, ultrasonically for 5 minutes, transfer to an autoclave, heat at 120°C for 4 hours, wash the resulting solid with methanol three times, and dry it in a vacuum oven at 60°C for 12 hours to obtain a magnetic core-shell Bimetallic MOF materials.

Embodiment 2

[0031] Example 2 Preparation of magnetic core-shell bimetallic MOF-2 material

[0032] Add 0.05 g of Fe3O4 nanoparticles into a beaker containing 2 g of polyvinylpyrrolidone and 30 mL of methanol. After sonicating for 30 minutes, 0.98 g of 2-methylimidazole was added to the mixture, which was then sonicated for another 5 minutes. At the same time, 0.446 g of zinc nitrate hexahydrate and 0.4365 g of cobalt nitrate hexahydrate were weighed and dissolved in 30 mL of methanol. After mixing the two solutions above, ultrasonically for 5 minutes, transfer to an autoclave, heat at 120°C for 4 hours, wash the resulting solid with methanol three times, and dry it in a vacuum oven at 60°C for 12 hours to obtain a magnetic core-shell Bimetallic MOF-2 materials.

Embodiment 3

[0033] Example 3 Preparation of magnetic core-shell bimetallic MOF-3 material

[0034] Add 0.05 g of Fe3O4 nanoparticles into a beaker containing 2 g of polyvinylpyrrolidone and 30 mL of methanol. After sonicating for 30 minutes, 0.98 g of 2-methylimidazole was added to the mixture, which was then sonicated for another 5 minutes. At the same time, 0.801 g of zinc nitrate hexahydrate and 0.087 g of cobalt nitrate hexahydrate were weighed and dissolved in 30 mL of methanol. After mixing the two solutions above, ultrasonically for 5 minutes, transfer to an autoclave, heat at 120°C for 4 hours, wash the resulting solid with methanol three times, and dry it in a vacuum oven at 60°C for 12 hours to obtain a magnetic core-shell Bimetallic MOF-3 materials.

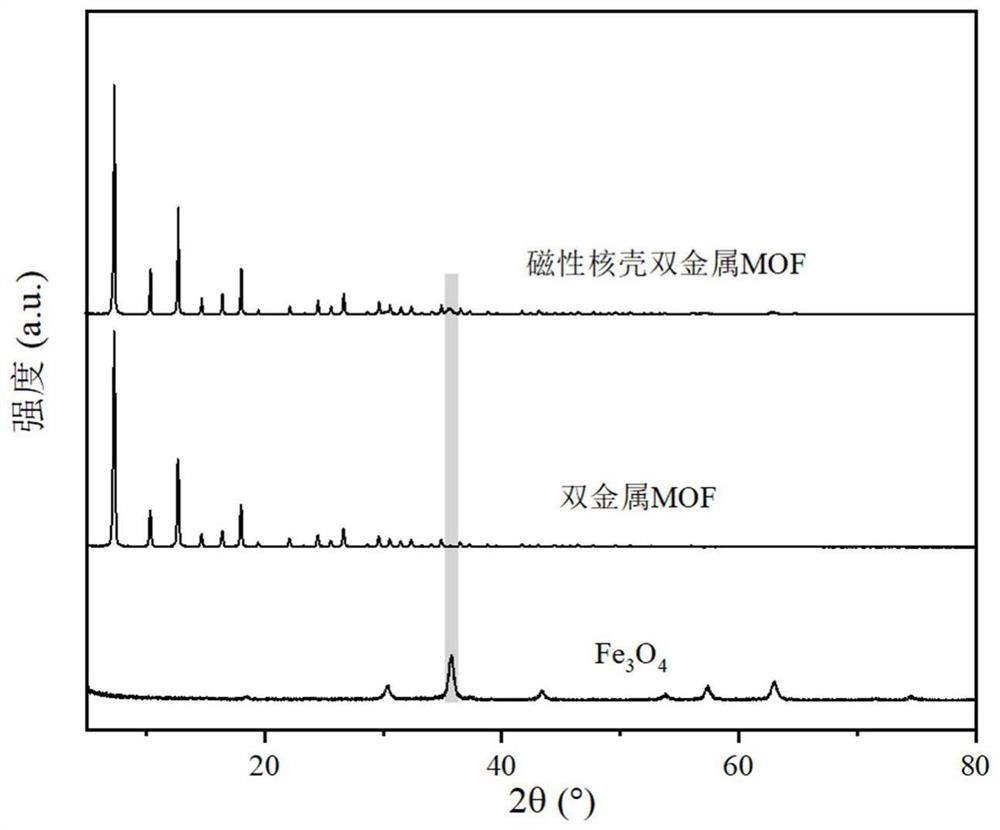

[0035] Depend on figure 1 It can be seen that the magnetic core-shell bimetallic MOF material prepared in Example 1 has both Fe 3 o 4 and the characteristic peaks of bimetallic MOF, indicating that the material is indeed Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com