Stable lifting system of tower crane

A tower crane and hoisting system technology, which is applied in the directions of cranes, load hoisting elements, transportation and packaging, etc., can solve problems such as difficulty in grasping the hoisting speed, jib shaking structure, safety accidents, etc., and achieve reliable performance, The effect of reducing potential safety hazards and being less prone to false triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

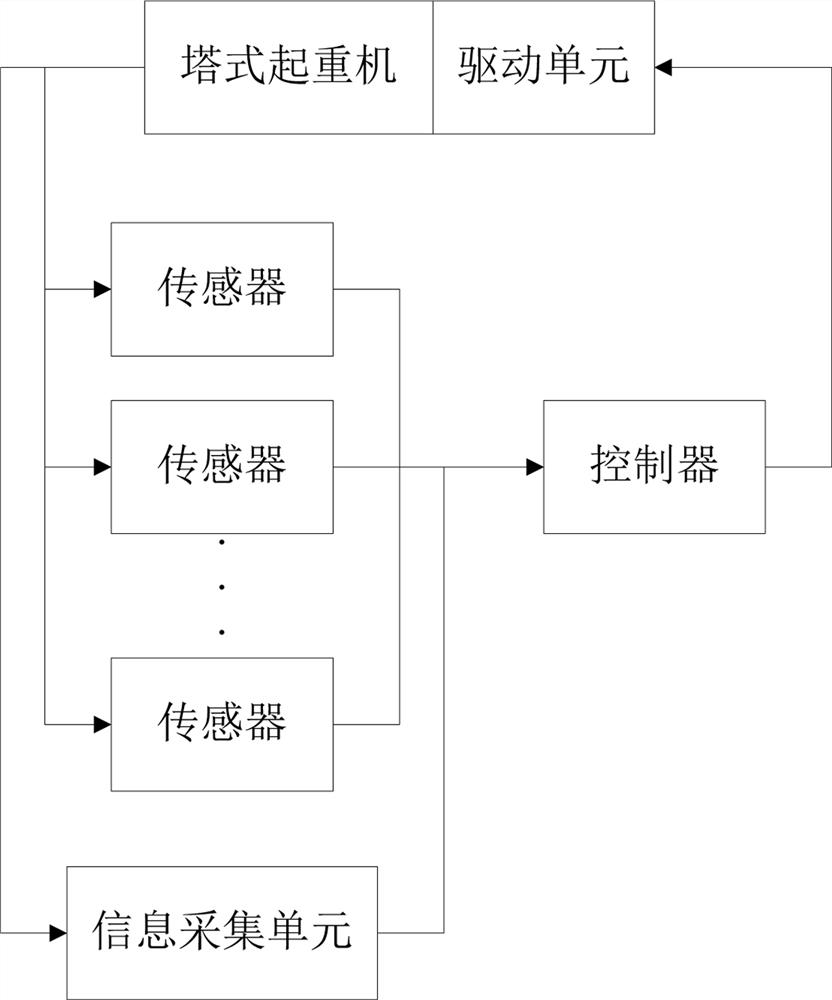

[0029] The invention relates to a stable lifting system of a tower crane, and the system is arranged in cooperation with the tower crane;

[0030] The system includes:

[0031] One or more sensors for obtaining real-time status signals of the tower crane;

[0032] The sensor includes a distance sensor arranged in cooperation with the jib beam of the tower crane, the distance sensor is arranged facing the horizontal ground; the sensor is arranged in cooperation with the controller.

[0033] An information collection unit, used to collect the working status signal of the tower crane;

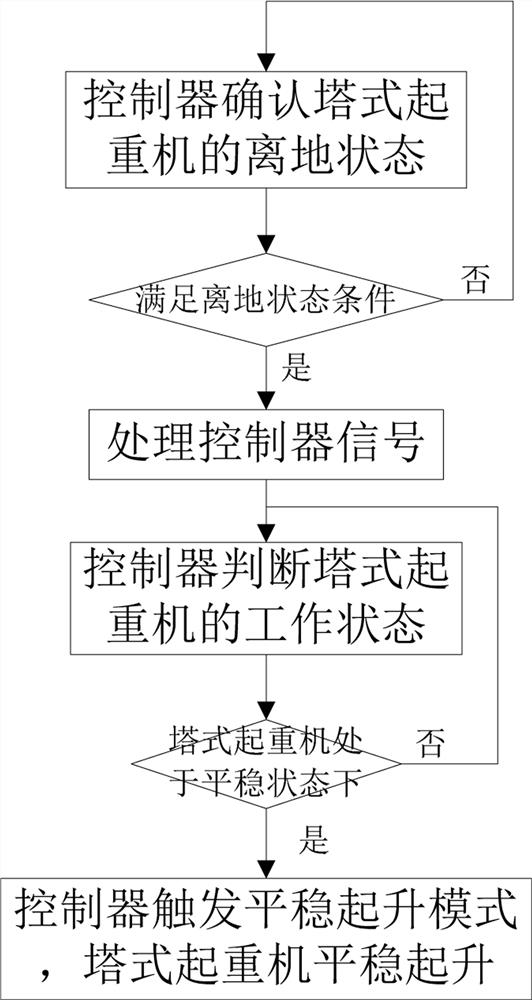

[0034] The ground-lift condition in step 1 includes data fed back from sensors and information collection units, and the tower crane is in a normal state and has not yet been hoisted.

[0035] a drive unit, used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com