Ultrahigh-pressure nano homogenizer

A nano-homogenizer and ultra-high pressure technology, applied in mixers, dissolution, chemical instruments and methods, etc., can solve the problems of unsatisfactory homogenization effect, prolonged refinement time, insufficient shear force, etc. time, improving crushing efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

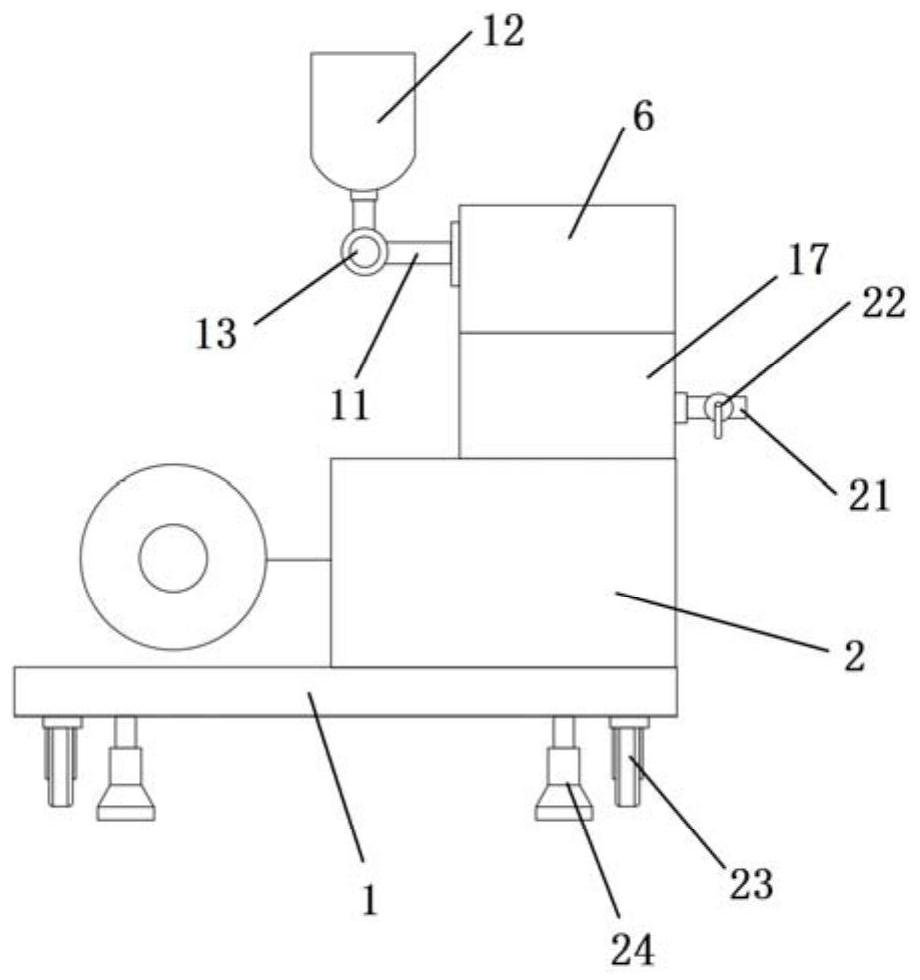

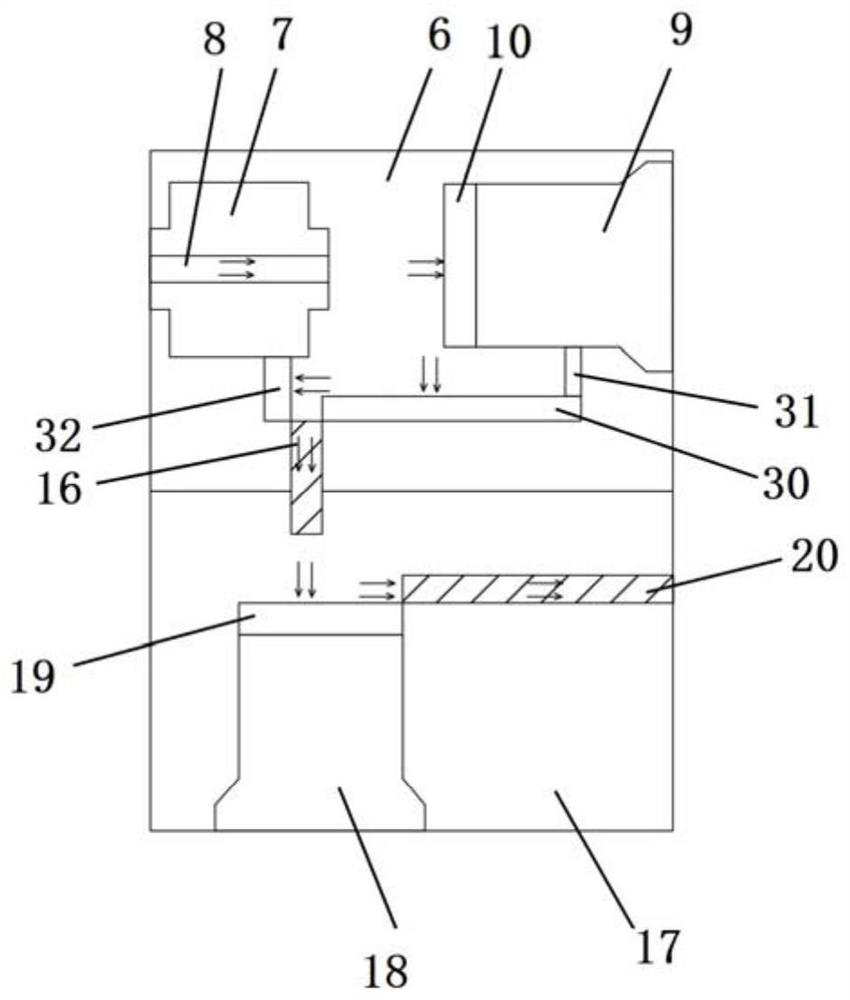

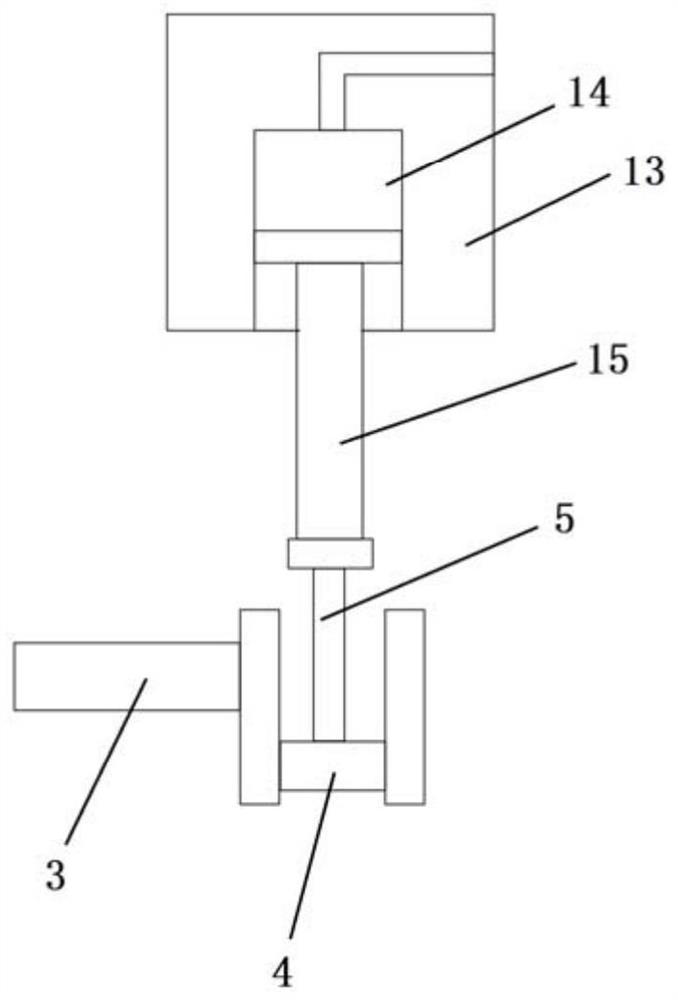

[0024] Embodiment 1 of the present invention discloses a kind of ultra-high pressure nanometer homogenizer, such as figure 1 and figure 2As shown, including the base 1, the top of the base 1 is fixedly provided with a crankcase 2, the top of the crankcase 2 is fixedly provided with a primary homogenizing mechanism 6 and a secondary homogenizing mechanism 17, and the primary homogenizing mechanism 6 is located at the secondary homogenizing mechanism 17 Directly above, the primary homogenizing mechanism 6 and the secondary homogenizing mechanism 17 are connected through the first material channel 16, and the valve seat 7 and the first valve core 9 are arranged opposite to each other along the horizontal direction in the primary homogenizing mechanism 6, and the valve A second material channel 8 is opened on the seat 7 along the horizontal direction, and a first homogenizing head 10 is fixedly arranged on the end of the first valve core 9 facing the valve seat 7, and a second ma...

Embodiment 2

[0030] Embodiment 2 of the present invention discloses an ultra-high pressure nano homogenizer, and embodiment 2 has the same basic features as embodiment 1, and both have the following distinguishing technical features: Figure 5 and Image 6 As shown, the connection between the first homogenizing head 10 and the first valve core 9 and the connection between the second homogenizing head 19 and the second valve core 18 are all set in a zigzag structure, and the material is ejected from the second material passage 8 under high pressure. , when hitting the first homogenizing head 10 on the first spool 9 and the subsequent hitting on the second homogenizing head 19 on the second spool 18, a huge impact force will be generated, by putting the first homogenizing head The connection between 10 and the first valve core 9 and the connection between the second homogenizing head 19 and the second valve core 18 are all set in a sawtooth structure, which can effectively buffer and dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com