Grape seed extract tablet candy and preparation method thereof

A technology for tableting candies and extracts, used in confectionery, confectionery industry, food science and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

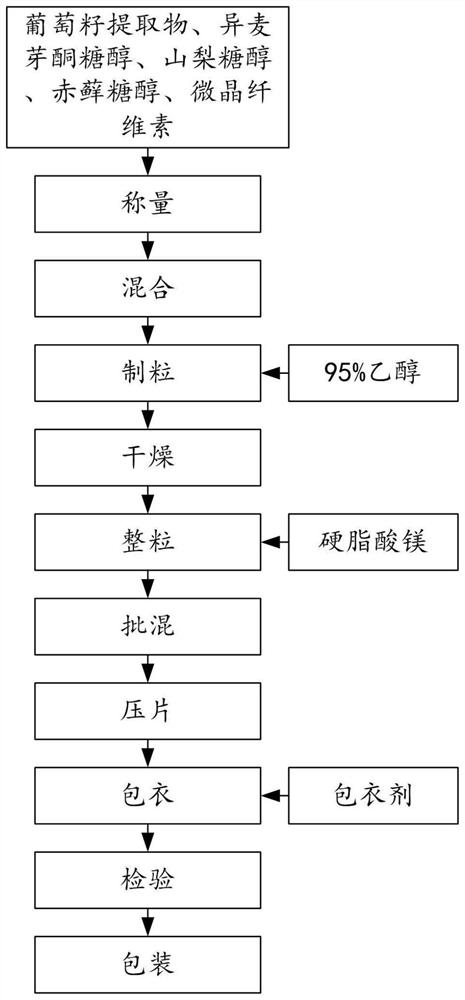

[0074] A preparation method of a grape seed extract tablet candy of the present invention mainly comprises the following steps:

[0075] Step 1. Weighing

[0076] Grape seed extract, isomalt, sorbitol, erythritol, and microcrystalline cellulose were weighed according to the proportions;

[0077] Step 2. Mixing

[0078] Add the weighed grape seed extract, isomalt, sorbitol, erythritol, and microcrystalline cellulose into the mixer and mix for 30-50 minutes, and stir evenly;

[0079] Step 3. Granulation

[0080] Add 95% ethanol to the above mixture, and add it to a granulator for granulation;

[0081] Step four, drying

[0082] The prepared granules are placed at a temperature of 40 to 45 ° C for drying treatment, and the drying time is: 45 to 60 min;

[0083] Step 5. Whole grain

[0084]Pass the dried granules through a 15-20 mesh sieve;

[0085] Step 6, batch mixing

[0086] Weigh magnesium stearate according to the proportion, add it to the above-mentioned mixed granu...

Embodiment 1

[0094] Example 1 Preparation of Grape Seed Extract Tablet Candy

[0095] Weigh out 225g of grape seed extract, 170g of isomalt, 60g of sorbitol, 20g of erythritol, and 15g of microcrystalline cellulose, respectively, add them to the mixer and mix for 30min, and stir evenly; the above mixture is added to the granulation. The granulation was carried out in the machine, and an appropriate amount of 95% ethanol was added during the granulation process; the obtained granules were dried at a temperature of 50 ° C for 45 minutes; the dried granules were passed through a 16-mesh sieve; 10 g of magnesium stearate was weighed and added to In the mixed granules after the above-mentioned granulation, mix for 30min; use a tablet machine to perform tableting treatment; add 10g of coating agent and mix and carry out coating treatment, 10g of coating agent contains 6.235g of hydroxypropyl methylcellulose; titanium dioxide 0.5g; talcum powder 1g; polyethylene glycol 1g; erythritol 0.8g; carame...

Embodiment 2

[0096] Example 2 Preparation of Grape Seed Extract Tablet Candy

[0097] Weigh out 210 g of grape seed extract, 150 g of isomalt, 55 g of sorbitol, 15 g of erythritol, and 15 g of microcrystalline cellulose, respectively, and add them to the mixer and mix for 30 minutes, and stir evenly; the above mixture is added to the granulation. The granulation was carried out in the machine, and an appropriate amount of 95% ethanol was added during the granulation process; the obtained granules were dried at a temperature of 50 ° C for 45 minutes; the dried granules were passed through a 16-mesh sieve; 10 g of magnesium stearate was weighed and added to In the mixed granules after the above-mentioned granulation, mix for 30min; use a tablet machine to perform tableting treatment; add 10g of coating agent and mix and carry out coating treatment, 10g of coating agent contains 6.235g of hydroxypropyl methylcellulose; titanium dioxide 0.5g; talcum powder 1g; polyethylene glycol 1g; erythrito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com