Method for determining maximum single-shot explosive quantity during blasting

A technology to determine the method and dosage, which is applied in the field of materials to achieve the effects of improving safety, controlling mining costs and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

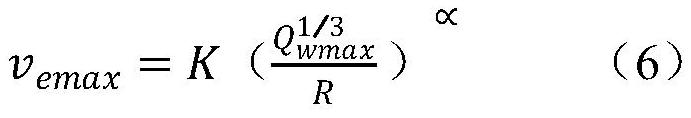

[0048] Embodiment 1: a method for determining the maximum single shot charge during blasting, the specific steps are as follows:

[0049] (1) According to the one-dimensional longitudinal wave propagation theory of a slender rod, the relationship between the force on the particle and the velocity of the particle

[0050] σ=-ρc 0 v (1)

[0051] In the formula: the negative sign means that the direction of stress and velocity is opposite during the propagation of stress wave, ρc 0 is the wave impedance of the propagation medium, ρ is the density of the medium, kgm -3 , c 0 is the propagation velocity of one-dimensional longitudinal wave in the medium, ms -1 ;

[0052] Equation (1) deduces

[0053]

[0054] σ emax =-ρc 0 v emax (3)

[0055] σ pmax =-ρc 0 v pmax (4)

[0056] In the formula: ρ is the medium density, kgm -3 , c 0 is the propagation velocity of one-dimensional longitudinal wave in the medium, ms -1 ; σ emax is the maximum dynamic compressive stre...

Embodiment 2

[0086] Embodiment 2: This embodiment takes the blasting site of Dahongshan Copper Mine as an example;

[0087] A method for determining the maximum single shot charge during blasting, the specific steps are as follows:

[0088] According to the proportioning parameters of the cemented ore pillars of the B10-15 line in the middle section of 285, the strengths of the cemented filling body of the layered filling are 1.75Mpa and 2.34Mpa respectively, so only the results of these two strengths are listed. In Table 1,

[0089] According to the selected Sadovsky empirical formula, combined with formulas 14-28 and table 1, calculate the positions of filling bodies with different strengths at different detonation center distances (to verify the maximum section charge of the first mine blasting design in the stope, etc. (Calculated from effective detonation heart distance) to reach the maximum single-shot dose required for stability, and the specific dose control range is shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com