Device and method for testing density of high-temperature and high-pressure cement paste

A high-temperature and high-pressure water and mud density technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve problems such as imperfection, difficulty, and lack of simulated formation environment, so as to alleviate engineering and technical problems, simplify cumbersome procedures, and strengthen adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

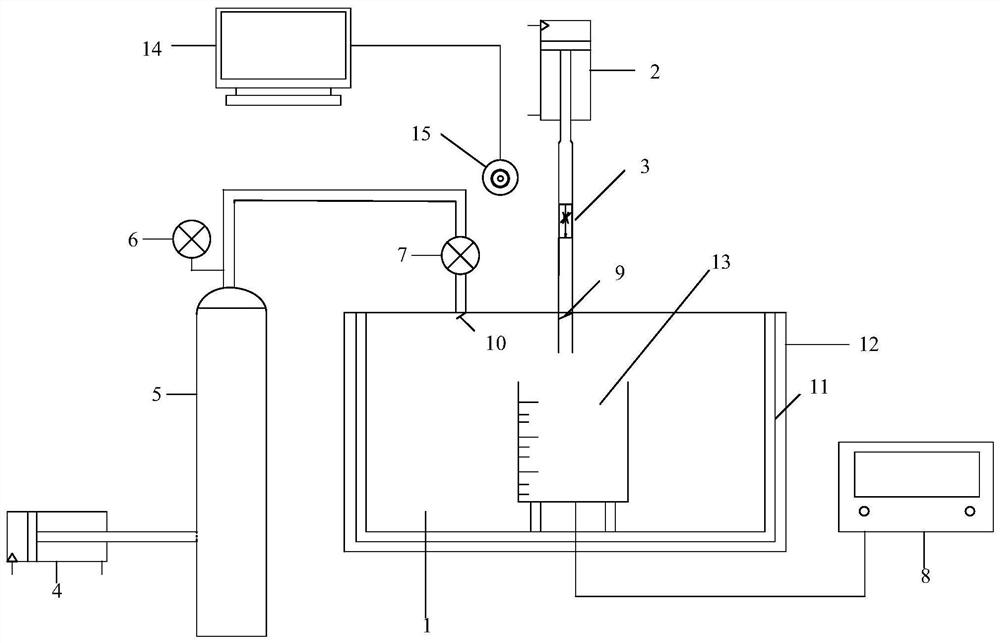

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the technical features in the embodiments can be combined with each other. It should be noted that, unless otherwise specified, all technical and scientific terms used in this application have the same meaning as commonly understood by those of ordinary skill in the art to which this application belongs.

[0025] In the present invention, the terms "first", "second" and the like are used to distinguish similar objects, rather than to describe a specific order or sequence, unless stated otherwise. The terms used should be understood as such; use of the terms "upper", "lower", "left", "right", etc. generally refers to the orientation shown in the drawings, or to the parts themselves in vertical, perpendicular or In terms of the direction of gravity; similarl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com