Movable slag bed

A driving device and body technology, applied in the field of metallurgical slag treatment, can solve the problems of high equipment and soil construction costs and operating costs, unfavorable continuous production, and large floor space, saving the length and area of the workshop, and avoiding the problem of slag falling. , the effect of reducing the cost of manufacturing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The object of the present invention is to provide a moving slag bed in a metallurgical slag treatment device.

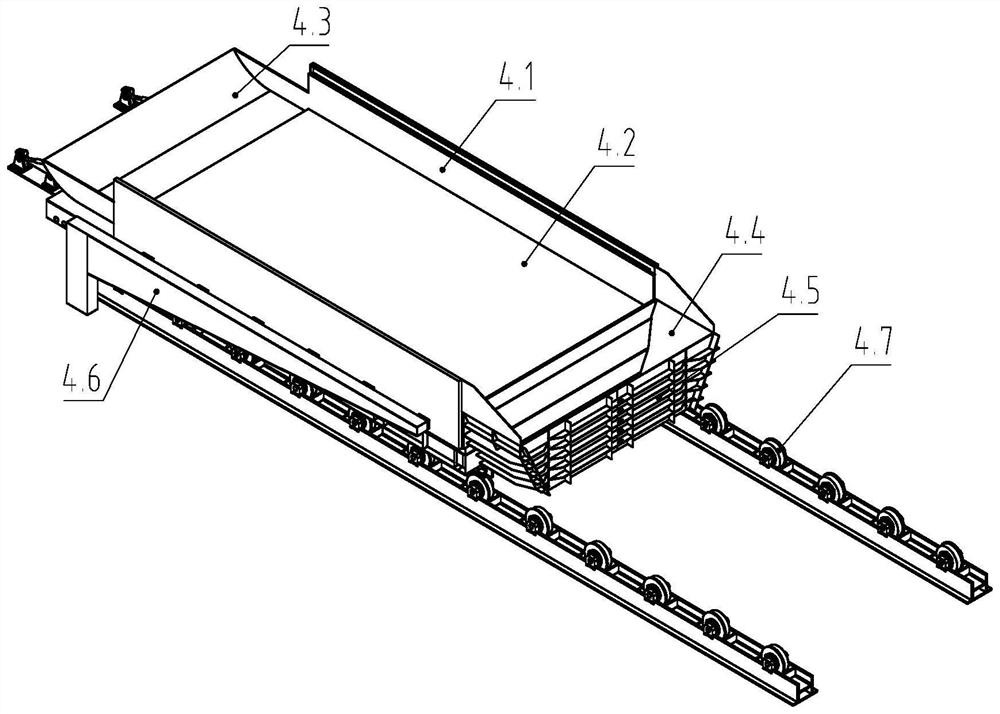

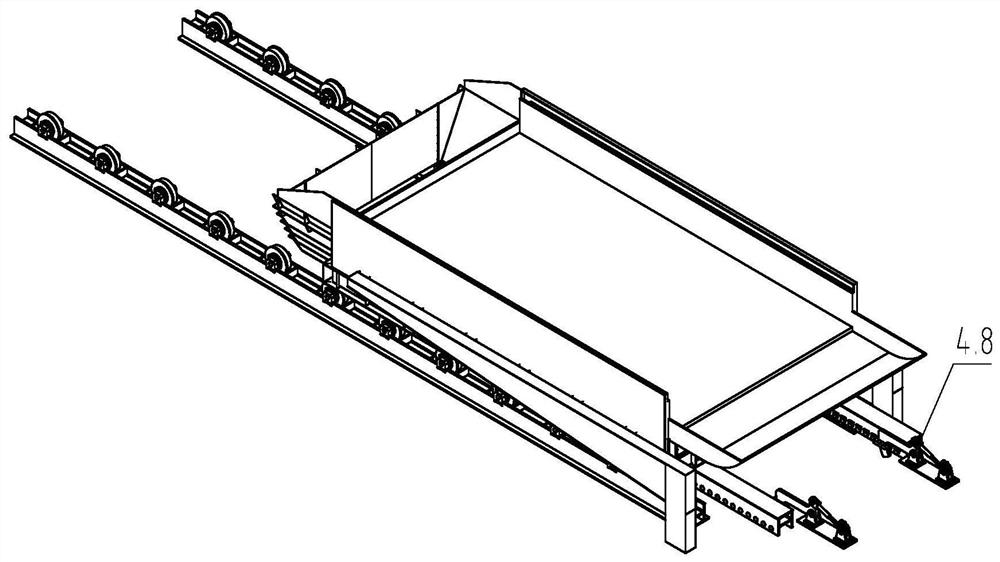

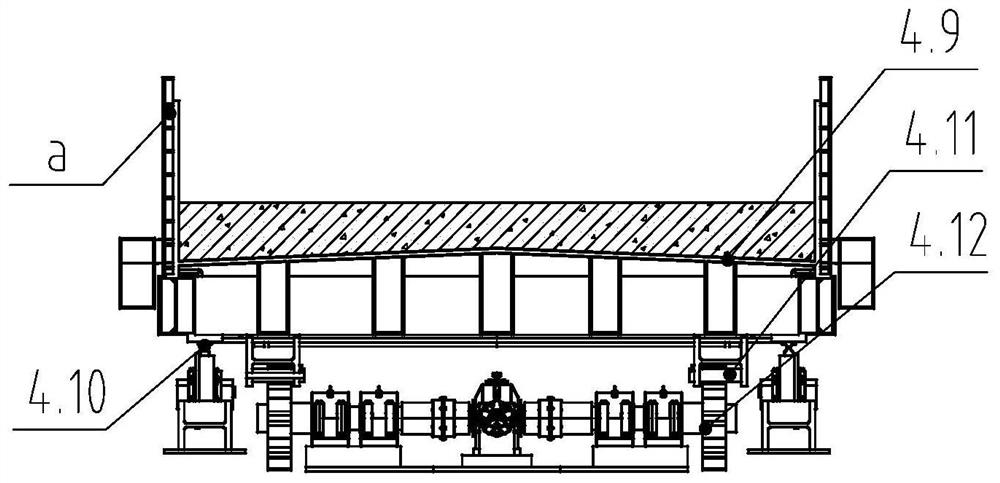

[0030] The mobile slag bed according to the present invention includes a mobile slag bed body, a slag bed discharge opening, a ground support system, a ground driving device for the mobile slag bed and a locking device for the mobile slag bed, wherein,

[0031] The moving slag bed body is welded by a slag bed bottom plate, a slag bed side plate and a slag bed expansion groove. The other end of the bed body, the inside of the slag bed body is laid with a cold slag layer, the inside of the side plate of the slag bed is provided with a cooling water channel, the bottom plate of the slag bed is high in the middle and low on both sides,

[0032] The ground support system is arranged on the ground, and the ground support system includes a plurality of support wheels and a base. The bottom of the slag bed is provided with a slag bed moving support rail, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com