Comprehensive arrangement method of bauxite raw storage pile

A bauxite and storage yard technology, applied in storage devices, conveyors, mechanical conveyors, etc., can solve the problem of increased road paving area and pipeline laying length, increased factory land area, factory infrastructure investment and production and operation costs. and other problems, to achieve the effect of reducing production and operation costs, compact layout, and reducing investment in engineering infrastructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

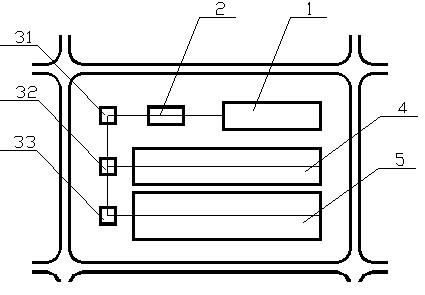

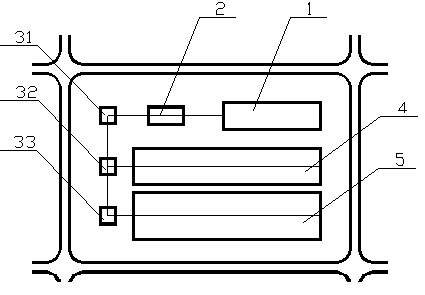

[0009] Embodiments of the present invention: first build the ore open-air storage yard 4, and then build the ore unloading system 1, the ore crushing system 2 and the ore homogenization storehouse 5 in parallel on both sides thereof. The first transfer station 31 is built at the back end of the ore crushing system 2, the second transfer station 32 is built at the back end of the ore open-air storage yard 4, and the third transfer station 33 is built at the back end of the ore homogenization storehouse 5. The transfer stations are connected to each other by belt transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com