Configuration of boiler houses in alumina plant

A configuration method and boiler room technology, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of factory production environment impact, increase factory infrastructure investment, increase factory land area, etc., to reduce infrastructure investment and production and operation costs, low production and production and operation costs, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

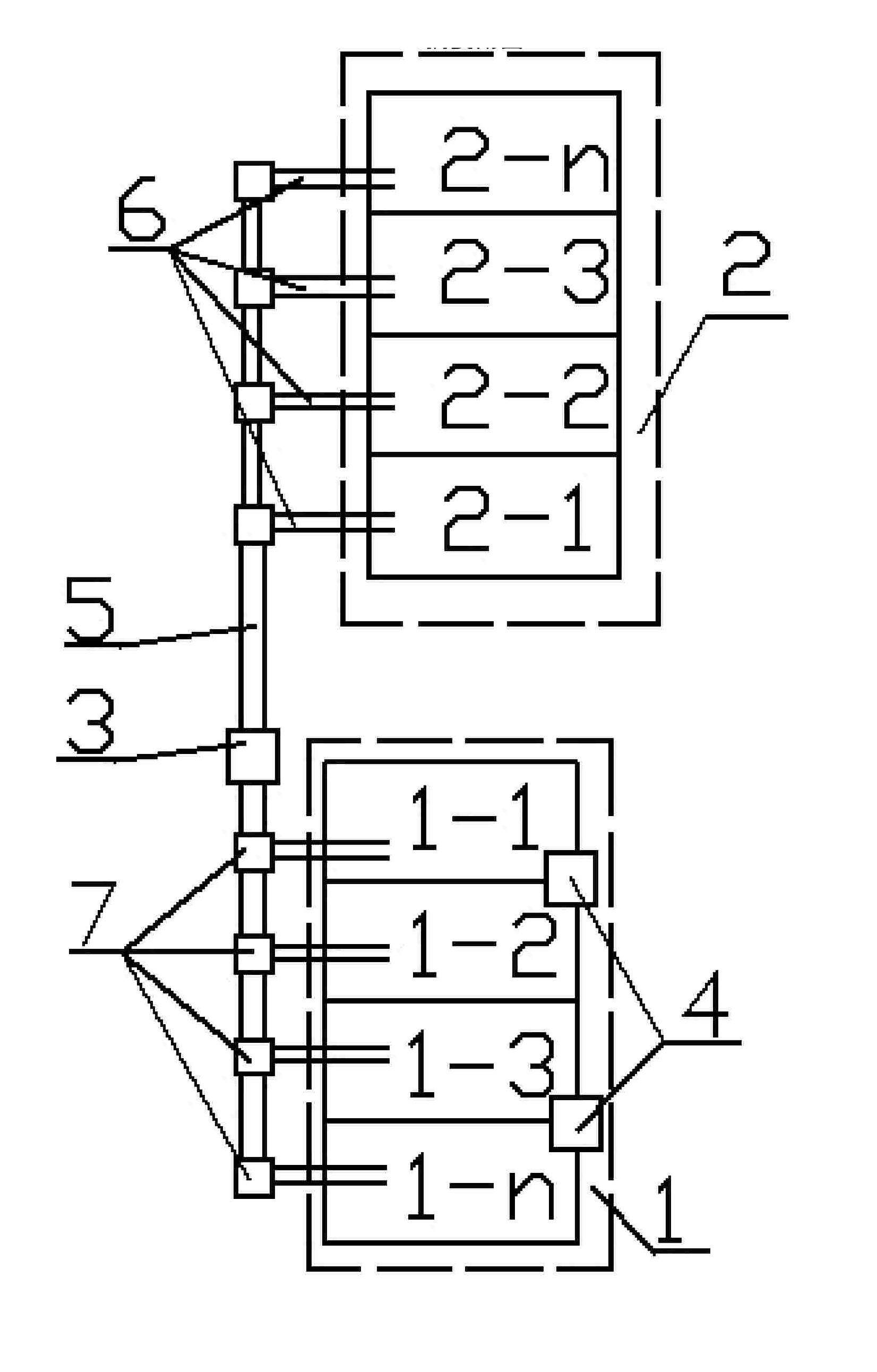

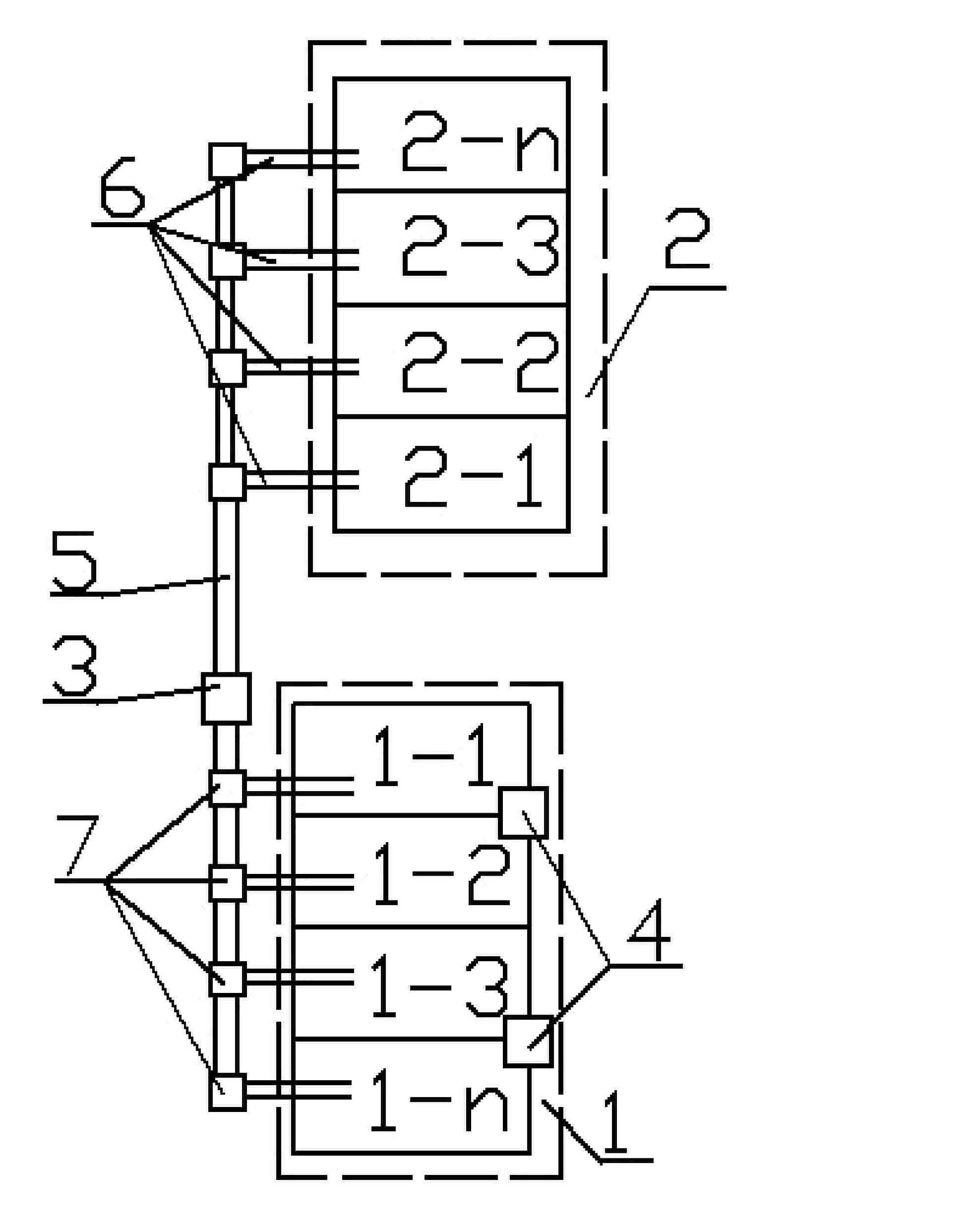

[0011] Example: As shown in Figure 1, during the factory layout design and initial planning, firstly, the overall planning of the coal supply system is laid out in the factory according to factors such as the source direction of the coal source of the aluminum plant, the local weather conditions, and the location of the steam user. A corner of the factory area that can be in the downwind direction for a long time, and a side door is opened at this corner to facilitate the passage of coal vehicles to reduce the pollution of coal to the factory area environment. Then the boiler facility 1 is concentrated at one end of the factory area. The boiler facility 1 is composed of the first-phase boiler facility 1-1, the second-phase boiler facility 1-2, the third-phase boiler facility 1-3 and the N-phase boiler facility 1-N; And the first-phase boiler facilities 1-1, the second-phase boiler facilities 1-2, the third-phase boiler facilities 1-3 and the N-phase boiler facilities 1-N are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com