Dry type heat recovery wine cooling system and method

A heat recovery and cooling system technology, applied in the field of winemaking, can solve the problems of low efficiency, large limitations and high energy consumption, and achieve the effects of simple structure, novel method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

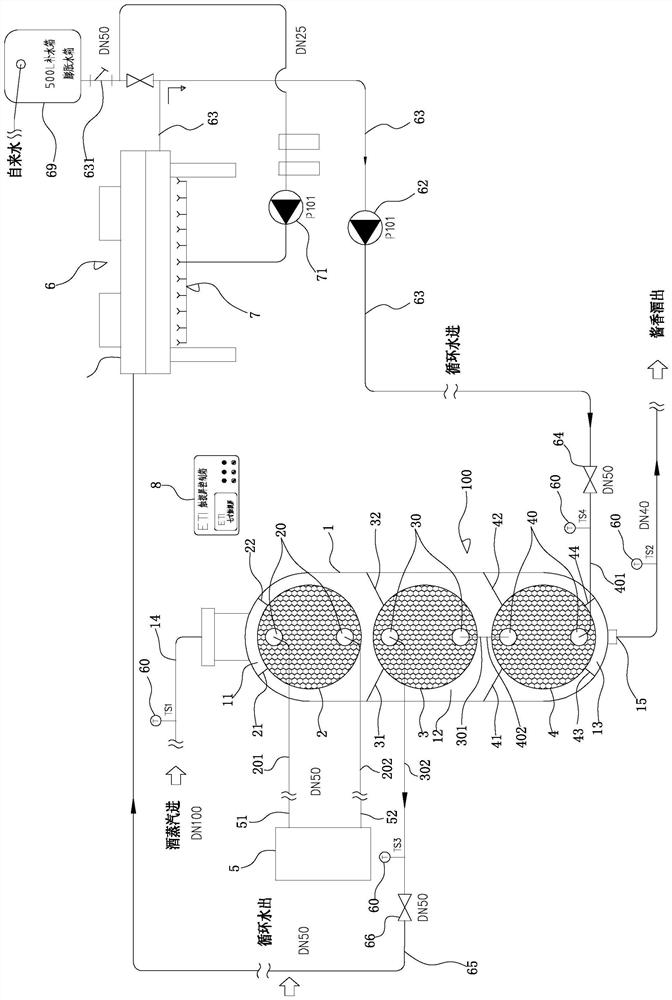

[0023] See figure 1 As shown, it is a dry heat recovery wine cooling system, which includes: a heat exchange device 100, which includes a shell 1 and a primary heat exchange core 2, a secondary heat exchange core 2, and a secondary heat exchanger installed in the shell 1 from top to bottom. Heat core 3, a first shell-side flow channel 11 and a second shell-side flow channel 12 that communicate with each other are respectively formed between the inner wall of the shell 1 and the primary heat exchange core 2 and the secondary heat exchange core 3, and the upper end of the shell 1 is provided with a A wine steam inlet 14 communicated with the first shell-side flow channel 11; a sauce-flavored wine outlet 15 communicated with the second shell-side flow channel 12 is provided at the lower end of the shell 1; The first plate-side flow channel 20 and the second plate-side flow channel 30 isolated from the first shell-side flow channel 11 and the second shell-side flow channel 12 are ...

Embodiment 2

[0028] See figure 2 As shown, the present invention is a dry heat recovery wine cooling system, which includes: a heat exchange device 100, which includes a shell 1 and a first-stage heat exchange core 2, a second-stage heat exchange core installed in the shell 1 sequentially from top to bottom. First-stage heat exchange core 3 and third-stage heat exchange core 4, the inner wall of the shell 1 and the first-stage heat exchange core 2, the second-stage heat exchange core 3 and the third-stage heat exchange core 4 are respectively formed with interconnected first shell-side flow channels 11. The second shell-side flow channel 12 and the third shell-side flow channel 13, and the upper end of the shell 1 is provided with a wine steam inlet 14 communicating with the first shell-side flow channel 11; Outlet 15; the primary heat exchange core 2, the secondary heat exchange core 3 and the tertiary heat exchange core 4 respectively have a first shell-side flow channel 11, a second sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com