Method for recovering sodium sulfate from white carbon black feed liquid

A technology of white carbon black and sodium sulfate, applied in the direction of alkali metal sulfite/sulfate purification, etc., can solve problems such as high cost and poor salt benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

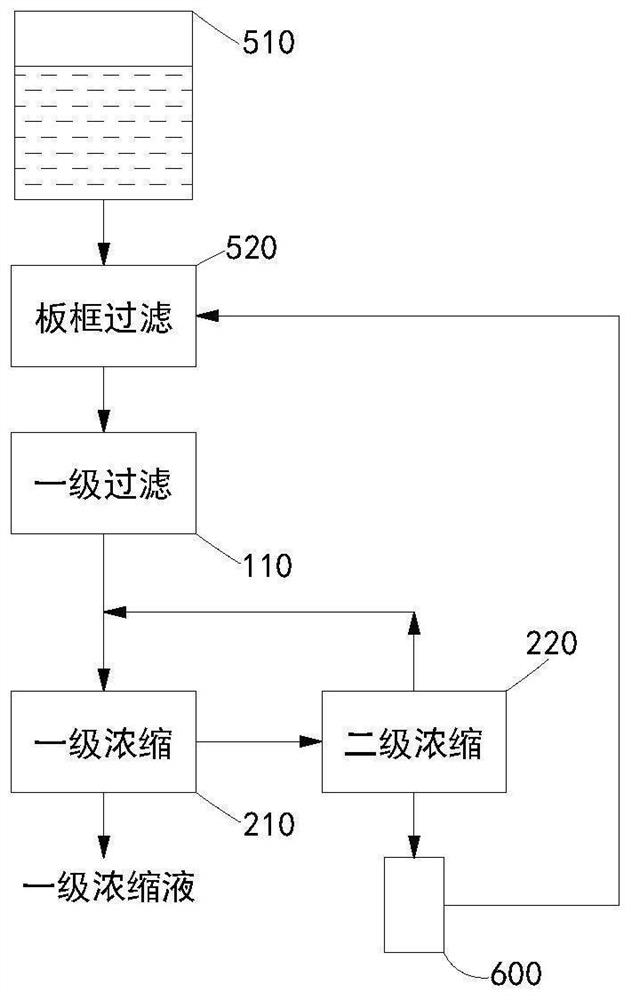

Embodiment 1

[0034] This embodiment provides the first specific implementation of the treatment method of the white carbon black feed liquid and the first specific implementation of the treatment system of the white carbon black feed liquid, wherein the white carbon black feed liquid is produced by the precipitation method In the process of preparing white carbon black, it is specifically the filtrate and washing water of plate and frame filtration of the acidification reaction feed liquid.

[0035] The processing method of white carbon black material liquid comprises steps:

[0036] (1) filtering the white carbon black material liquid to obtain a filtrate with SDI≤5;

[0037] (2) carry out membrane concentration to filtrate, obtain the membrane concentrate of sodium sulfate content ≥ 180g / L;

[0038] Wherein, the step (1) comprises: adopting the first filter medium with the interception rate ≥ 97% to the particles with a particle size ≥ 3nm to carry out primary filtration to the white ca...

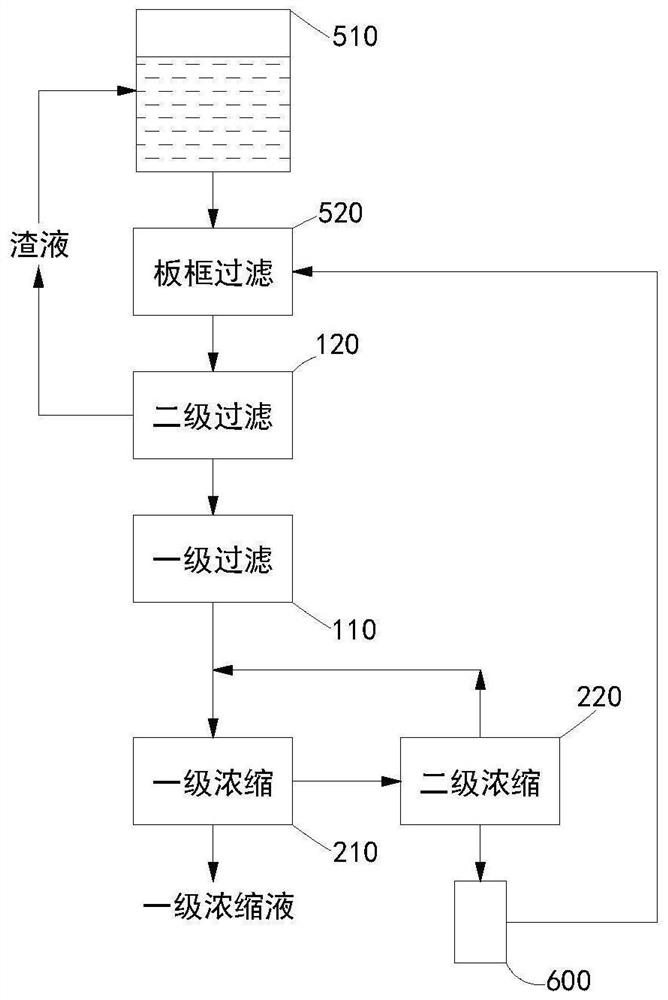

Embodiment 2

[0050] This embodiment provides the second specific implementation of the treatment method of the white carbon black feed liquid and the second specific implementation of the treatment system of the white carbon black feed liquid, wherein the white carbon black feed liquid is produced by the precipitation method In the process of preparing white carbon black, it is specifically the filtrate and washing water of plate and frame filtration of the acidification reaction feed liquid.

[0051] Compared with Example 1, the difference is that step (1) includes in the treatment method of the silica feed liquid of the present embodiment:

[0052] Step1: Use the second filter medium with an interception rate of ≥99% for particles with a particle size ≥30nm to perform secondary filtration on the silica feed liquid to obtain a secondary filtrate with a turbidity ≤10NTU; the second filter medium is made of titanium-based metal filter element;

[0053] Step2: Use the first filter medium wi...

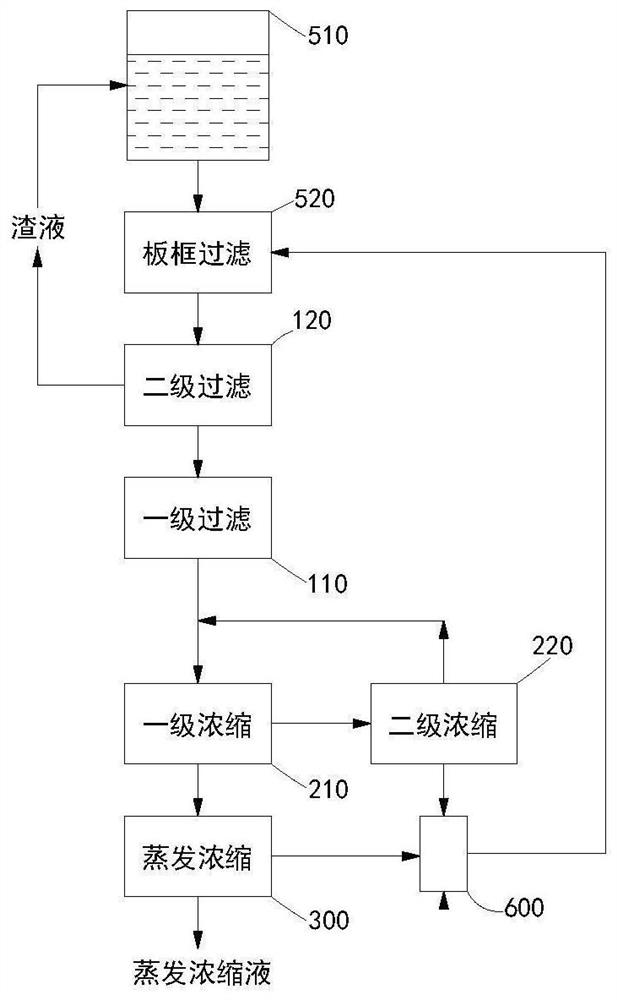

Embodiment 3

[0058] This embodiment provides the third specific implementation of the treatment method of the white carbon black feed liquid and the third specific implementation of the treatment system of the white carbon black feed liquid, wherein the white carbon black feed liquid is produced by the precipitation method In the process of preparing white carbon black, it is specifically the filtrate and washing water of plate and frame filtration of the acidification reaction feed liquid.

[0059] Compared with Example 2, the difference is that the treatment method of the white carbon black feed liquid of this embodiment further includes step (3): evaporating and concentrating the membrane concentrate to obtain an evaporation concentrate with a sodium sulfate content of 280-320 g / L .

[0060] image 3 It is a structural schematic diagram of the treatment system of the white carbon black material liquid of this embodiment. like image 3 As shown, compared with Example 2, the treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com