Annular rotary air supply device for coal storage Eurosilo

A technology of air supply device and circular air duct, which is applied in the direction of packaging, transportation and packaging, mechanical equipment, etc., can solve the problems of slow gas, high volatile content of coal powder particles, inconvenient movement, etc., to ensure personal safety, The effect of high air supply efficiency and small maintenance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

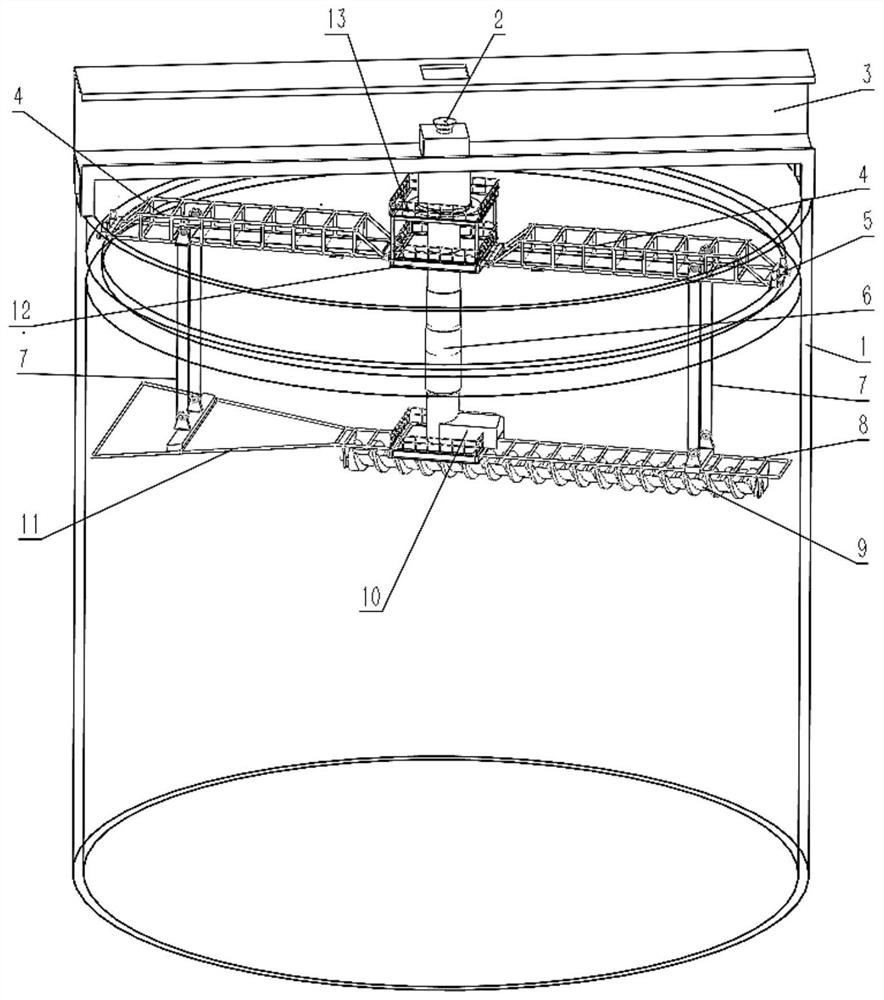

[0042] Such as figure 1 , the top of the barrel 1 of the Euro warehouse is provided with a warehouse top trestle 3, and a belt conveyor is arranged inside the warehouse top trestle 3, and a rotary trestle 4, a central telescopic blanking pipe 6, a spiral frame 8 and A The type frame 11, the spiral frame 8 and the A-type frame 11 are hung on the revolving trestle 4 through the lifting wire rope 7 and the hoist. The mechanism 5 is arranged on the circular track on the inner wall of the cylinder body 1. The center of the revolving trestle 4 is provided with a central winch platform 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com