Charging cooling system and battery swap station and energy storage station comprising same

A cooling system and charging bin technology, applied in the fields of charging and cooling systems, energy storage stations, and power swap stations, can solve problems such as the risk of water ingress that affect the appearance and image of the power swap station, and the poor heat dissipation effect, so as to eliminate the risk of water ingress, Avoid adverse effects, effect of high cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

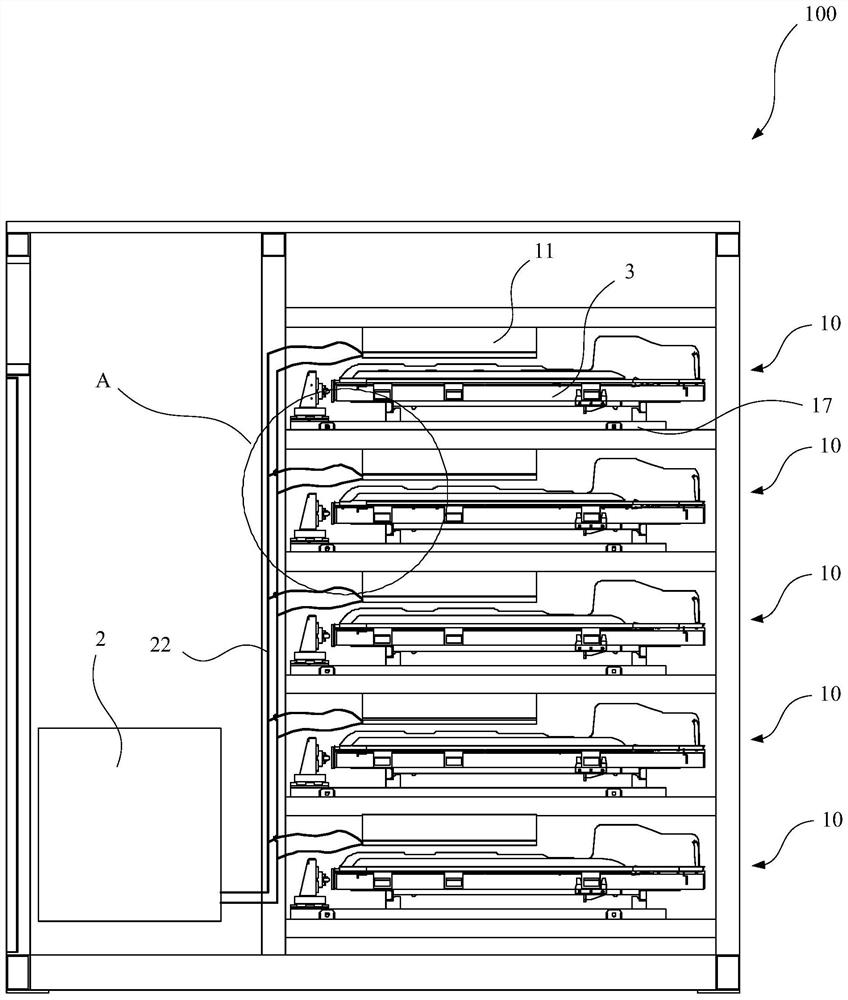

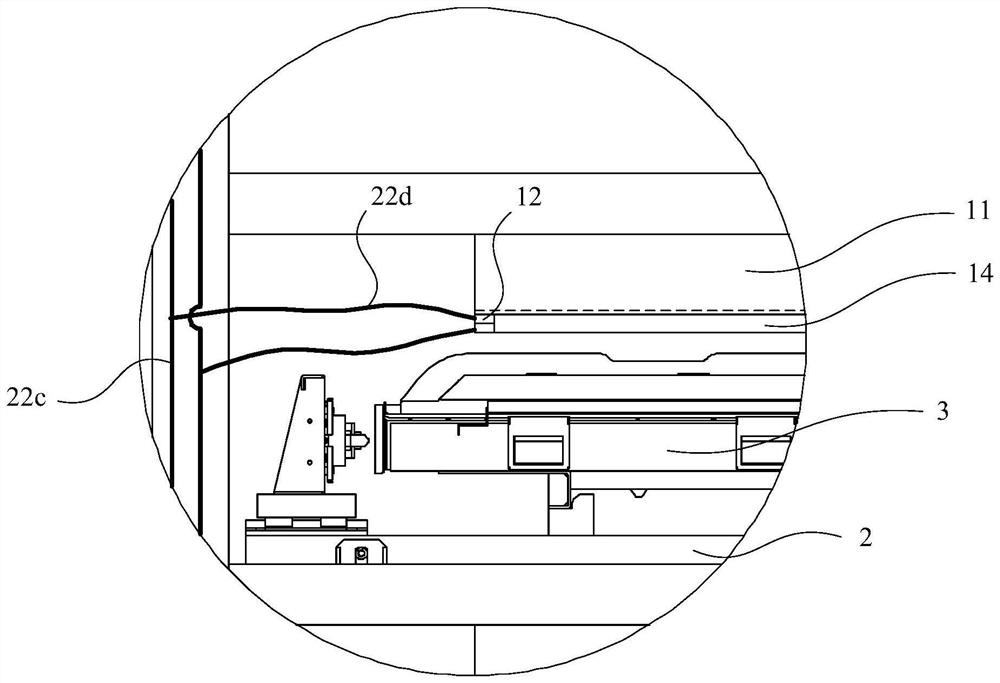

[0075] The present invention provides a charging cooling system installed in the battery swap station 100 , the charging cooling system is used for cooling the charging module 11 of the battery swap station 100 . like figure 1 and figure 2 As shown, the power exchange station 100 includes several charging bins 10, and each charging bin 10 includes a corresponding charging module 11. The power swapping station 100 also includes a liquid cooling system 2, which is used to charge these charging modules 11 For cooling, the charging module 11 is provided with a cooling interface 12 connected to the liquid cooling system 2 , so that the cooling liquid inside the liquid cooling system 2 can cool the charging module 11 .

[0076] The charging cooling system cools the charging module 11 through the liquid cooling system 2, so as to have a higher cooling effect compared with traditional air-cooling cooling, thereby improving the heat dissipation effect on the charging module 11, and p...

Embodiment 2

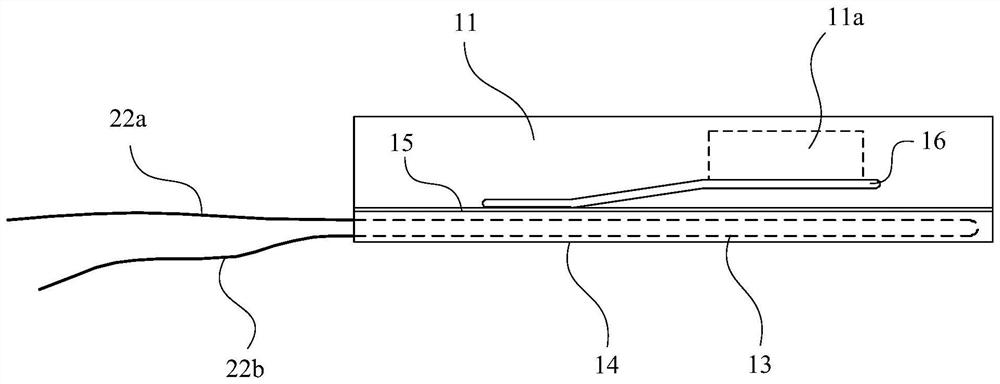

[0102] This embodiment provides a charging cooling system, the structure of which is substantially the same as the charging cooling system provided in Embodiment 1, the difference is that in this embodiment, the cooling channel 13 of the charging module 11 is not located outside the charging module 11 , Instead, it is located inside the charging module 11 .

[0103] In this embodiment, the inside of the charging module 11 is provided with a cooling channel 13, and the cooling medium in the liquid cooling system 2 flows through the cooling channel 13 through the cooling interface 12 to directly dissipate heat from the heat source 11a inside the charging module 11. To achieve the purpose of improving heat dissipation efficiency. The cooling interface 12 is arranged on the outer wall surface of the charging module 11, and it is connected with the cooling pipe 22 of the liquid cooling system 2 through a cooling connector, so as to quickly cut off the connection between the chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com