A microchannel plate fixing device

A technology of micro-channel plate and fixing device, which is applied in the field of photoelectric detection, can solve the problems of slight damage on the surface of the device, high pressure of the micro-channel plate, and high pressure of the trapezoidal spring pressure ring, etc., to achieve the quantification of the clamping program, expand the application occasions, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

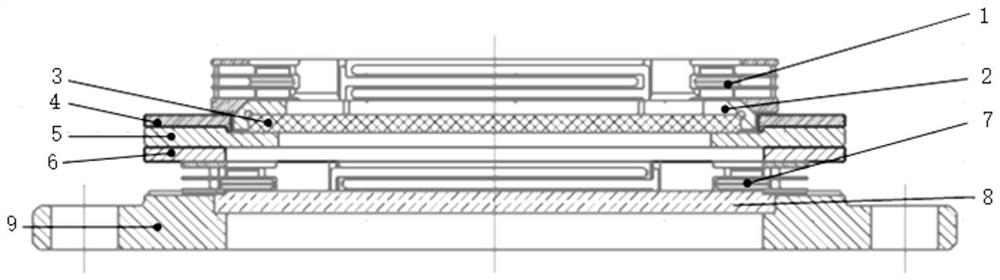

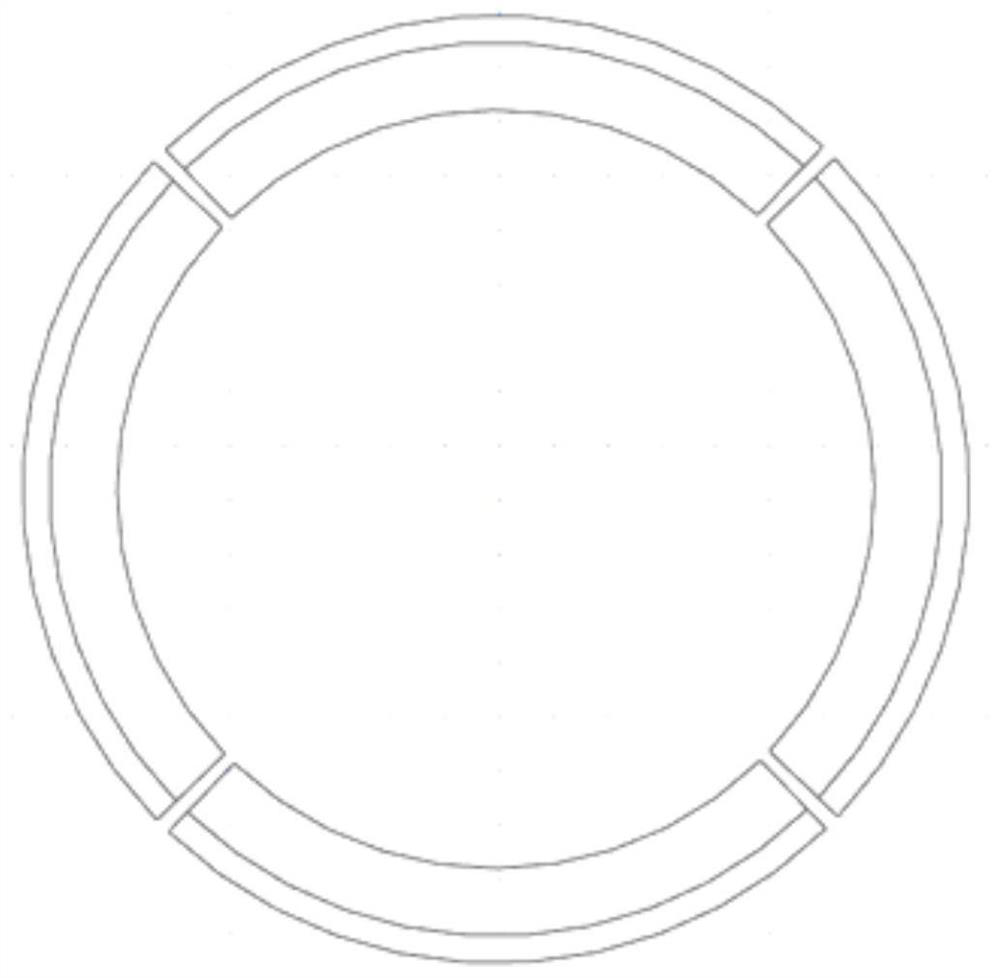

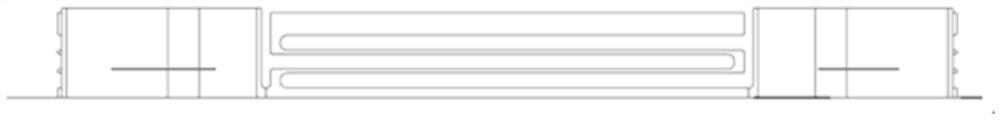

[0031] Please refer to figure 1 , a microchannel plate fixing device provided in the embodiment of the present application includes a ring-shaped base 9, a collector electrode 8, a second elastic pressing ring 7, an insulating plate 6, a microchannel plate base stacked on the base 9 in sequence 5. Insulation positioning ring 4, micro-channel plate 3, arc-shaped positioning ring 2, first elastic pressure ring 1, this embodiment fixes a micro-channel plate, by adjusting the mechanical size, the micro-channel plate base 5 and the first elastic pressure ring 1-3 microchannel plates can be placed between 1.

[0032] The upper surface of the base 9 is provided with a first groove, and the collector 8 is arranged in the first groove, and the collector 8 is used to receive the electron flow multiplied by the microchannel plate 3 .

[0033] The second elastic pressure ring 7 is arranged on the collector 8, the second elastic pressure ring 7 and the base 9 clamp the collector, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com