Spraying dust removal device of quartz sand crusher

A dust removal device and crusher technology, which is applied in the field of quartz sand dust removal, can solve problems such as explosions in workshops, large dust generation, and lung infections of users, and achieve the effects of protecting body safety, protecting the air environment, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

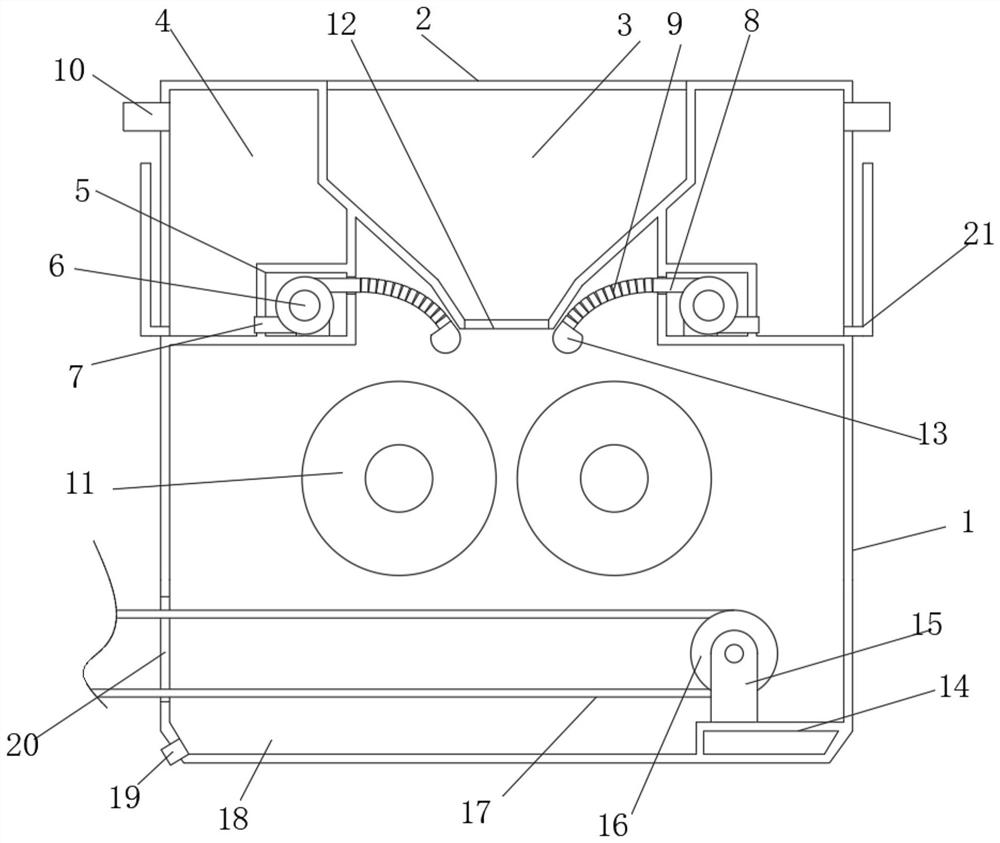

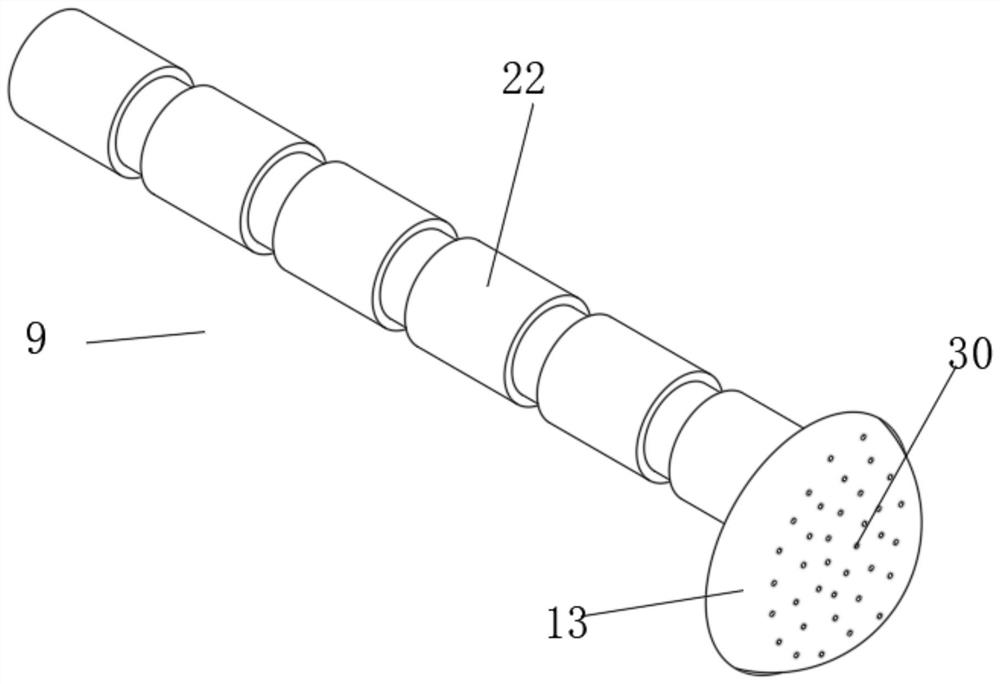

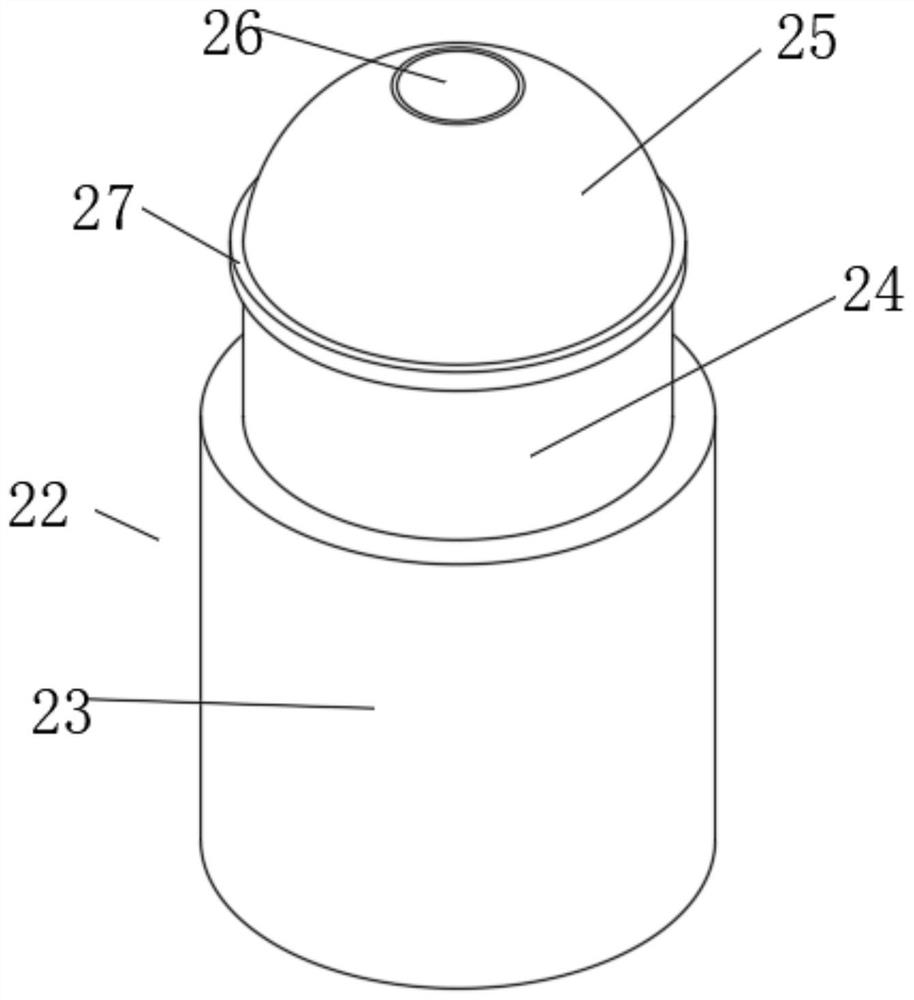

[0022] A spray dust removal device for a quartz sand crusher, in order to solve the problem that a large amount of dust will be generated during crushing, and the generated dust will be suspended in the air, affecting the air quality of the workshop, causing infection to the user's lungs, and even It may cause an explosion in the workshop and cause huge losses. The structure of the existing spraying device is fixed, and it is impossible to change the spraying angle according to the requirements. As a preferred embodiment, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a crusher shell 1, the top of the crusher shell 1 is provided with a material inlet 2, one end of the material inlet 2 is fixedly connected with a sand chamber 3, and the bottom of the sand chamber 3 is provided with a sand outlet 12, which contains The side of the sand chamber 3 is provided with a water chamber 4, and the bottom of the water chamber 4 is provided with a pump chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com