Manufacturing method and application of factory volatile organic compound removing device

A technology for organic compounds and manufacturing methods, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as low investment, and achieve the effects of protecting the air environment, strong practicability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

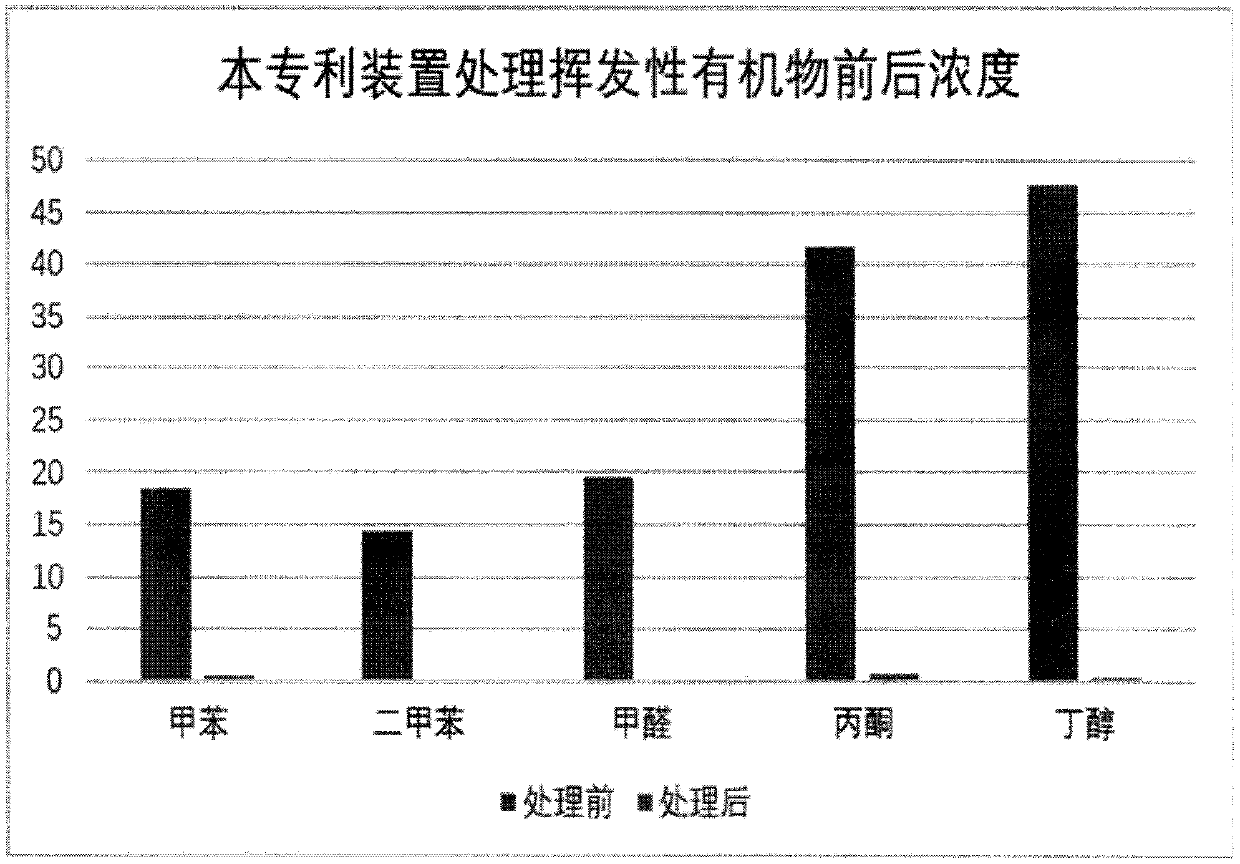

[0022] Embodiment 1: Air treatment in the workshop of an organic chemical factory

[0023] According to the above-mentioned technical route and scheme, the volatile organic compound removal device was assembled and debugged, and the test was carried out in an organic chemical factory workshop.

[0024] 1. On March 23, 2019, a test was carried out in an organic chemical factory workshop in Nanjing Dachang District. Before the test, the types and contents of volatile organic compounds in the air of the workshop were detected. The five volatile organic compounds and their concentrations were respectively; toluene 18.5mg / m 3 , Xylene 14.3mg / m 3 , formaldehyde 19.6mg / m 3 , acetone 41.6mg / m 3 , butanol 47.6mg / m 3 ;

[0025] 2 After using the device of the present invention to treat for 60 minutes, detect the concentration of 5 kinds of volatile organic compounds in the workshop air again, which are respectively: toluene 0.4mg / m 3 , Xylene 0.2mg / m 3 , formaldehyde 0.03mg / m 3 ,...

Embodiment 2

[0027] Example 2: Air treatment in the production workshop of a certain paint factory

[0028] According to the above-mentioned technical route and scheme, the volatile organic compound removal device was assembled and debugged, and the test was carried out in an organic chemical factory workshop.

[0029] 1. On May 14, 2017, I went to the workshop of a paint factory in Nanjing to conduct a test. Before the test, the types and contents of volatile organic compounds in the air of the workshop were detected. The three types of volatile organic compounds and their concentrations were respectively; toluene 26.2mg / m 3 , Xylene 35.9mg / m 3 , formaldehyde 24.1mg / m 3 ;

[0030] 2 After using the device of the present invention to treat for 90 minutes, detect the concentration of three kinds of volatile organic compounds in the workshop air again, which are respectively: toluene 0.5 mg / m 3 , Xylene 0.4mg / m 3 , formaldehyde 0.08mg / m 3 ;

[0031] 3. After 90 minutes of continuous tr...

Embodiment 3

[0032] Example 3 Air treatment in the paint shop of an auto repair factory

[0033] According to the above-mentioned technical route and scheme, the volatile organic compound removal device was assembled and debugged, and the test was carried out in an organic chemical factory workshop.

[0034] 1. On August 9, 2016, the test was carried out in the paint workshop of an auto repair factory in Nanjing Dachang District. Before the test, the types and contents of volatile organic compounds in the air of the workshop were detected. The 4 kinds of volatile organic compounds and their concentrations were respectively; toluene 52.5.5mg / m 3 , xylene 41.3mg / m 3 , formaldehyde 39.4mg / m 3 , Glycol ether 27.4mg / m 3 ;

[0035] 2 After using the device of the present invention to treat for 80 minutes, detect the concentration of 5 kinds of volatile organic compounds in the workshop air again, which are respectively: toluene 1.2mg / m 3 , xylene 0.8mg / m 3 , formaldehyde 0.1mg / m 3 , glycol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com