Non-contact voltage sensor

A voltage sensor, non-contact technology, applied in the direction of measuring only voltage, measuring current/voltage, phase angle between voltage and current, etc., can solve problems such as single function and error, achieve frequency bandwidth, high precision, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

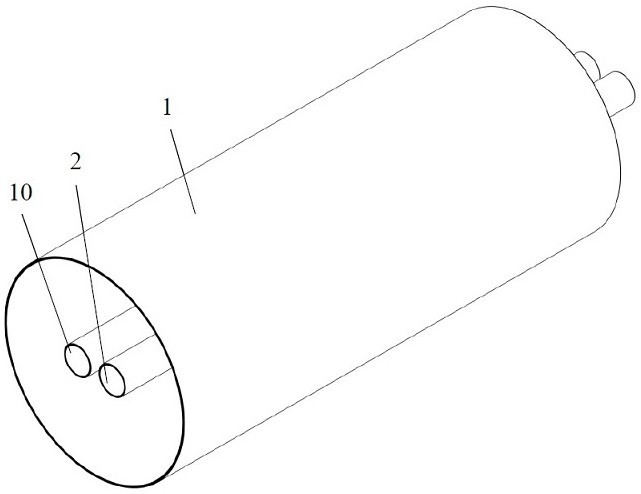

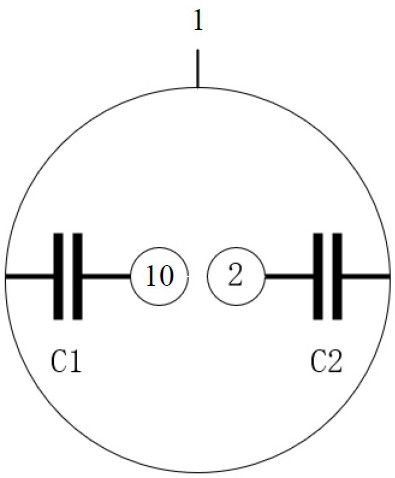

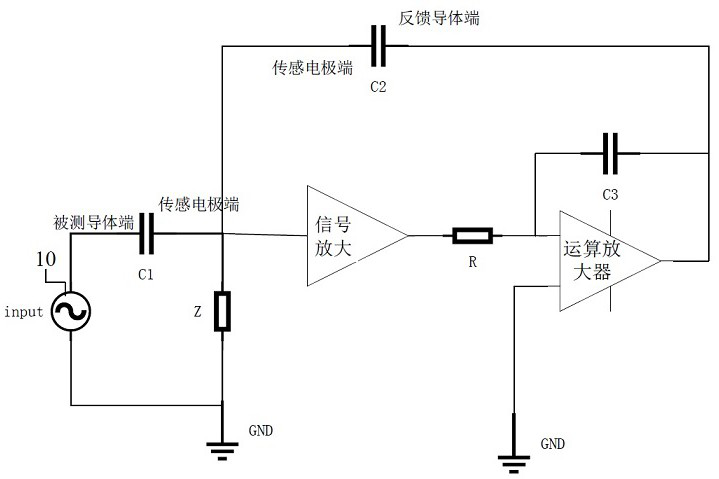

[0024] refer to figure 1 , figure 2 and image 3 , the voltage sensor of this embodiment includes a sensing electrode 1, a feedback conductor 2 and a signal amplification module. The sensing electrode 1 is made of conductive materials such as metal and semiconductor, and the measured conductor 10 and the feedback conductor 2 both pass through the non-enclosed space formed by the sensing electrode 1 . Such as figure 1 and figure 2 As shown, the sensing electrode 1 of this embodiment is hollow cylindrical, and the measured conductor 10 passes through the sensing electrode 1, and can form a coupling capacitance with the sensing electrode 1, and the measured conductor 10 and the sensing electrode The coupling capacitance formed between 1 is defined as the input coupling capacitance C1, and the voltage signal on the conductor 10 under test is collected through the input coupling capacitance. The feedback conductor 2 also passes through the sensing electrode 1, and it is spac...

Embodiment 2

[0030] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that: multiple feedback conductors (2_(1), 2_(2), ..., 2_(n)) are set in the sensing electrode 1, and multiple feedback conductors and the measured conductor 10 are evenly spaced along the circumferential direction, the positions of the measured conductor and each feedback conductor are rotationally symmetrical, and feedback coupling capacitance is formed between each feedback conductor and the sensing electrode 1 . Each feedback conductor is a conductor of the same shape made of the same material as the measured conductor, and each feedback conductor is connected to the output terminal of the signal amplification module. At this time, the feedback coupling capacitance is n times the input coupling capacitance (nC1≈ C2, that is, C2: C1 = n: 1, similarly, the difference between nC1 and C2 is considered to be approximately equal if the difference is within 10%, n is the number of feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com