Strip steel detection system and vertical quality inspection table manufacturing method

A technology of detection system and manufacturing method, which is applied to measurement devices, building structures, optical testing flaws/defects, etc., can solve the problems of complex detection devices and inconvenient double-sided detection of strip steel, and achieves reduction of hidden safety hazards and reduced power consumption. The effect of reducing consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

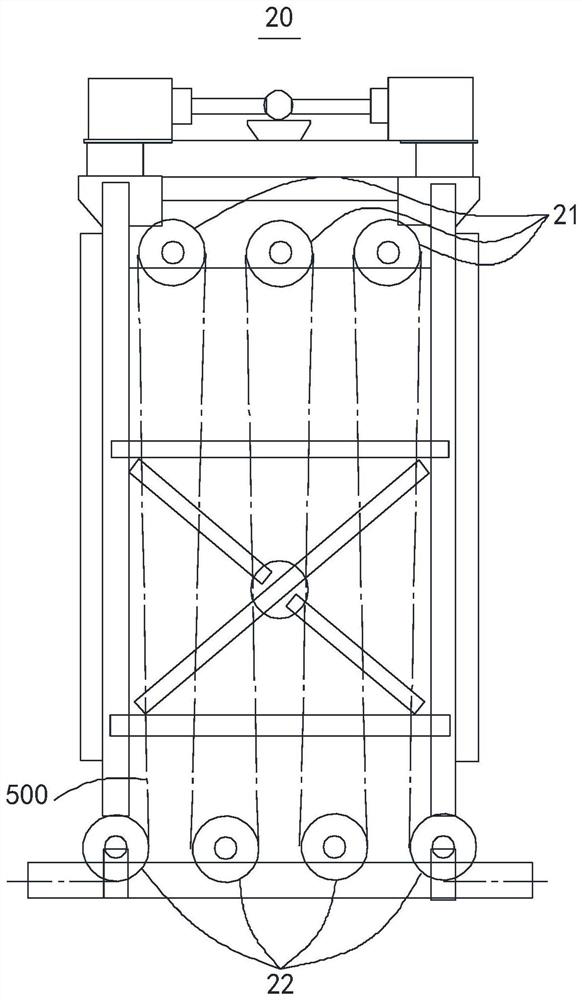

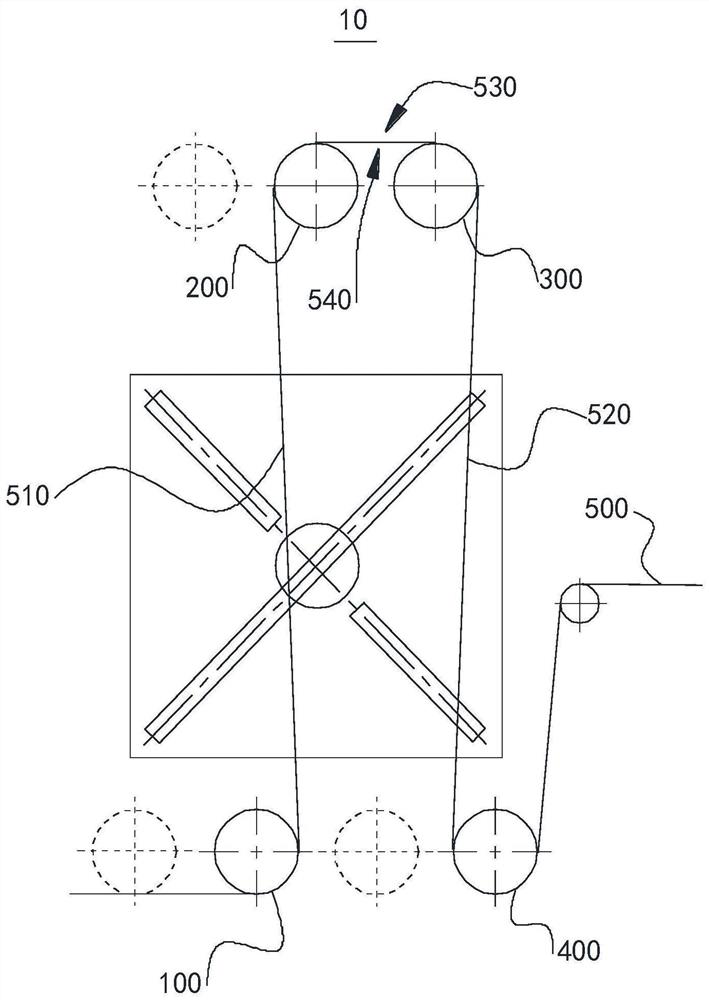

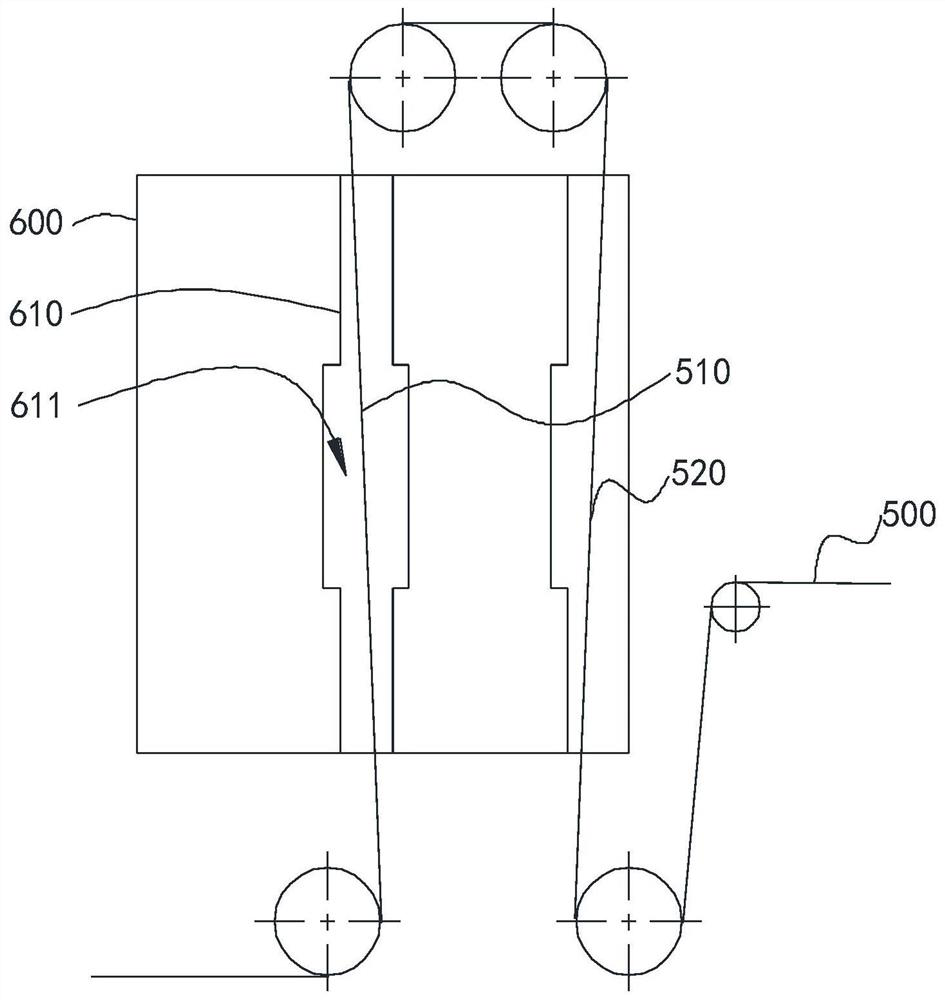

[0041] A strip steel detection system 10 is applied to an idle looper 20, the idle looper 20 includes a plurality of upper looper rolls 21 and a plurality of lower looper rolls 22, and the strip steel detection system 10 includes two upper looper rolls 21, The two lower looper rolls 22 and the quality inspection house 600 are distributed along the direction of the strip steel 500 as the first lower looper roll 100, the first upper looper roll 200, the second upper looper roll 300 and the second lower looper Roller 400, part of the strip steel 500 between the first lower looper roll 100 and the first upper looper roll 200 is the first vertical segment strip 510, the second upper looper roll 300 and the second lower looper roll 400 The portion of the strip 500 in between is a second vertical section of strip 520 havi...

Embodiment 2

[0067] The embodiment of the present application also provides a method for manufacturing a vertical quality inspection platform, which is used to manufacture the steel strip inspection system 10 in Embodiment 1. The method includes:

[0068] Preparation for installation of self-supporting floor deck and side formwork 630;

[0069] Self-supporting floor deck installation;

[0070] Side template 630 installation;

[0071] Steel bar 650 engineering and pipeline laying;

[0072] stud welding;

[0073] Concrete pouring. Finishing work is also carried out after concrete pouring.

[0074] Optionally, before the step of preparing for the installation of the self-supporting floor deck and side formwork 630, the removal of idle loops 20 is also carried out, and the removal of idle loops 20 includes:

[0075] In the idle looper 20, the looper rolls except the first upper looper roll 200, the second upper looper roll 300, the first lower looper roll 100 and the second lower looper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com