Visual inspection system for upper surface and lower surface of PCB and working method

A PCB circuit board, visual inspection technology, used in measuring devices, optical testing flaws/defects, material analysis by optical means, etc., can solve position and spacing errors, cannot perform double-sided simultaneous inspection, complex flip structure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

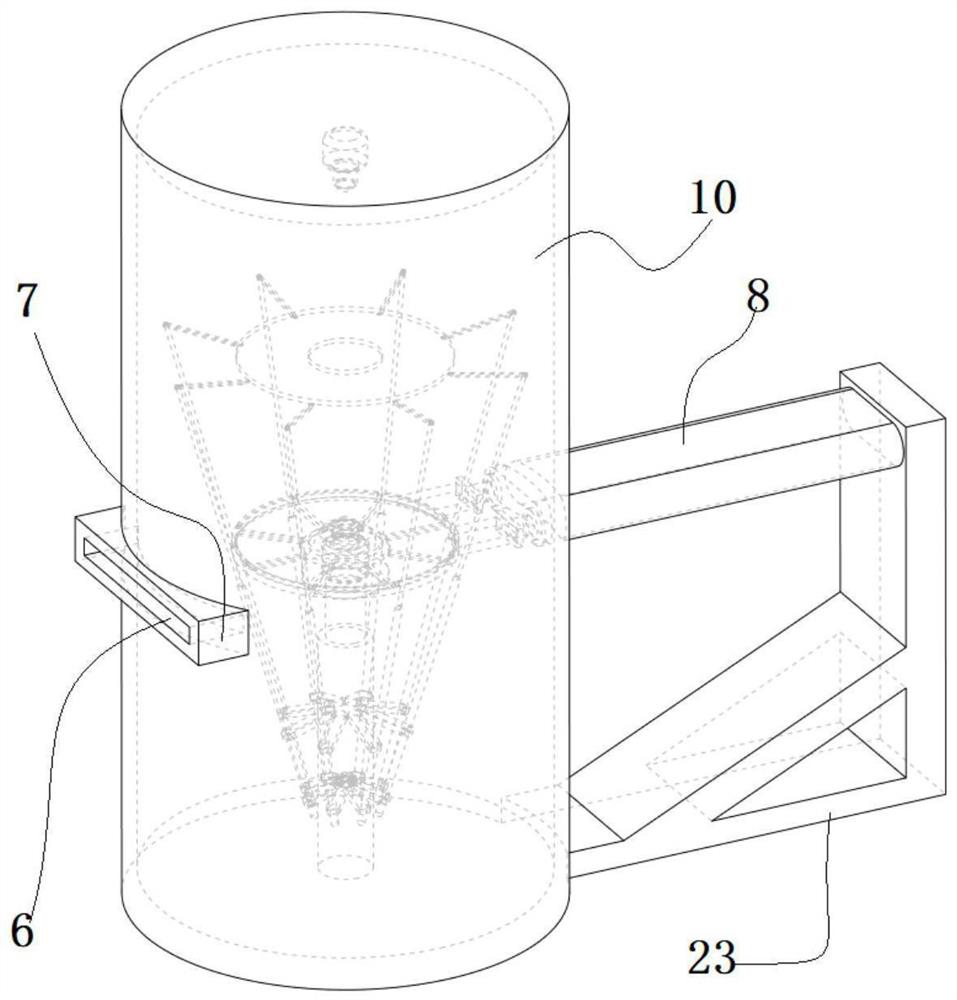

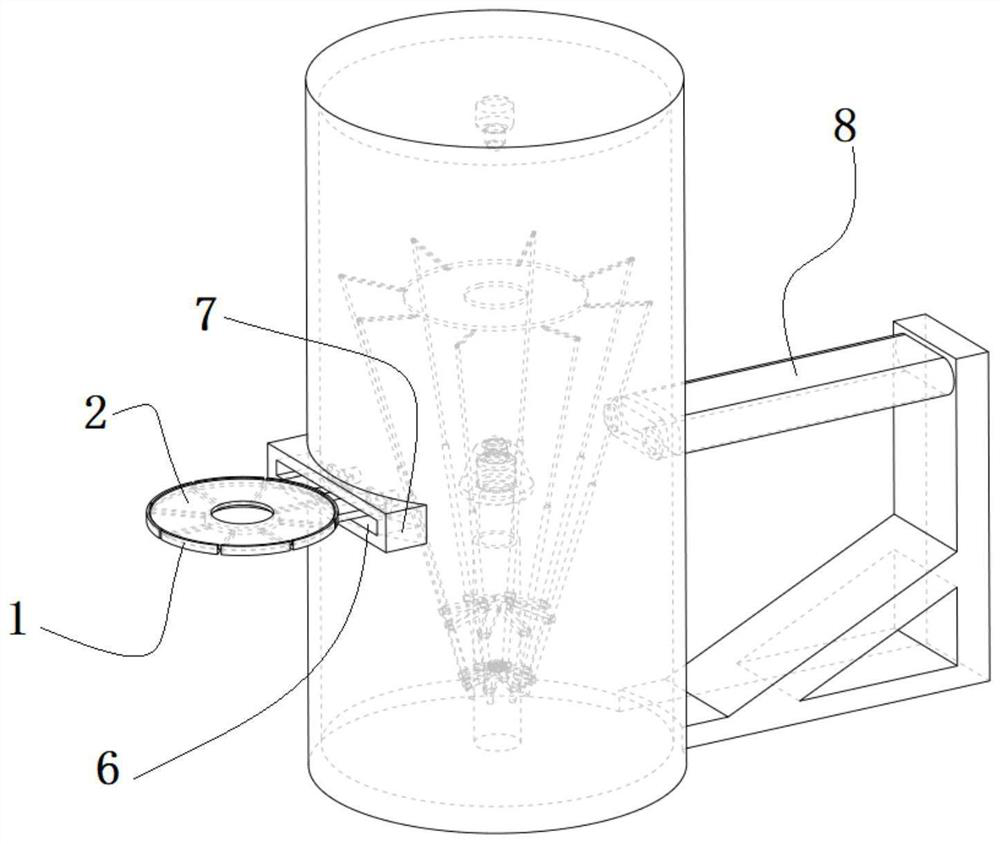

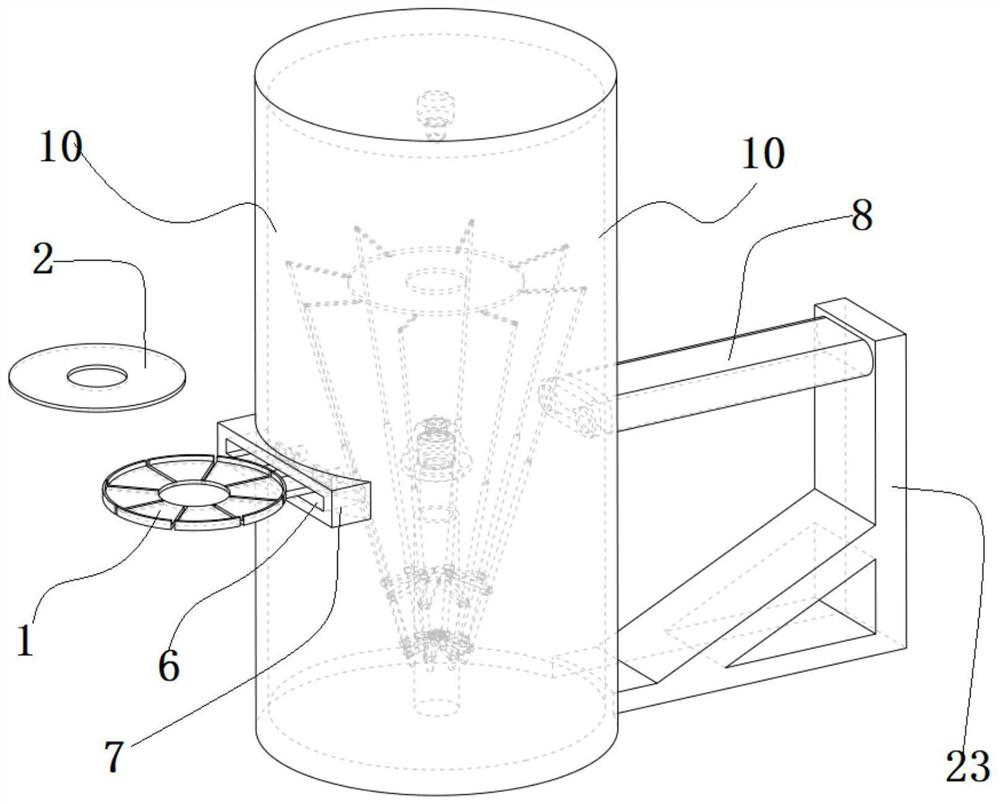

[0051] as attached Figures 1 to 14 The upper and lower visual detection system of the PCB circuit board shown includes a visual detection box body 10, and the visual detection box body 10 is a vertical visual detection darkroom 9, and the middle height of the visual detection darkroom 9 is provided with an overall circular shape. The PCB board placement platform 1, the ring-shaped PCB board 2 to be detected can be horizontally placed on the ring-shaped PCB board placement platform 1; the visual detection darkroom 9 in the present embodiment is provided with a light source for visual detection, and the second used in this program Both the first visual detection camera 32 and the second visual detection camera 11 are CCD cameras.

[0052] One side of the visual inspection box 10 is integrally provided with a mouth seat 7, and the mouth seat 7 is provided with a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com