A thermal induction self-lubricating bearing wear-resistant bushing

A self-lubricating, thermal induction technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of inconvenient operation, refueling, pertinence and poor flexibility, and achieve easy embedded installation and reduced friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

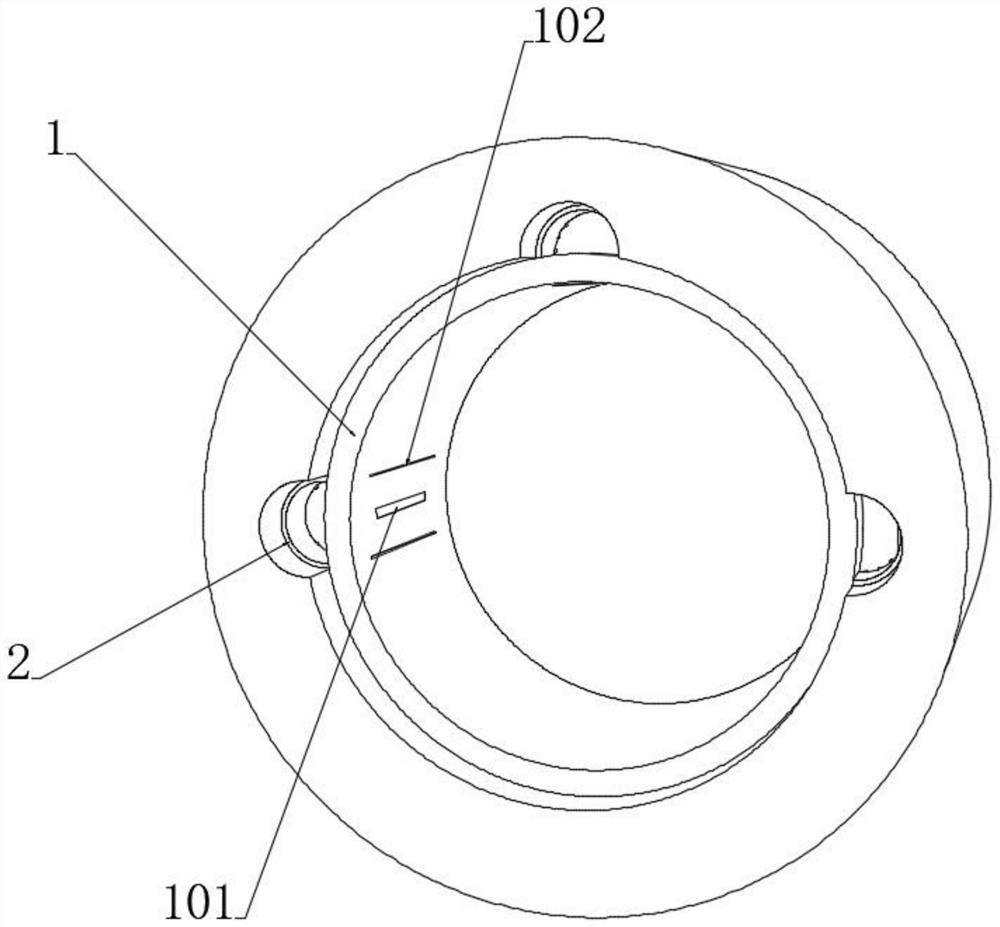

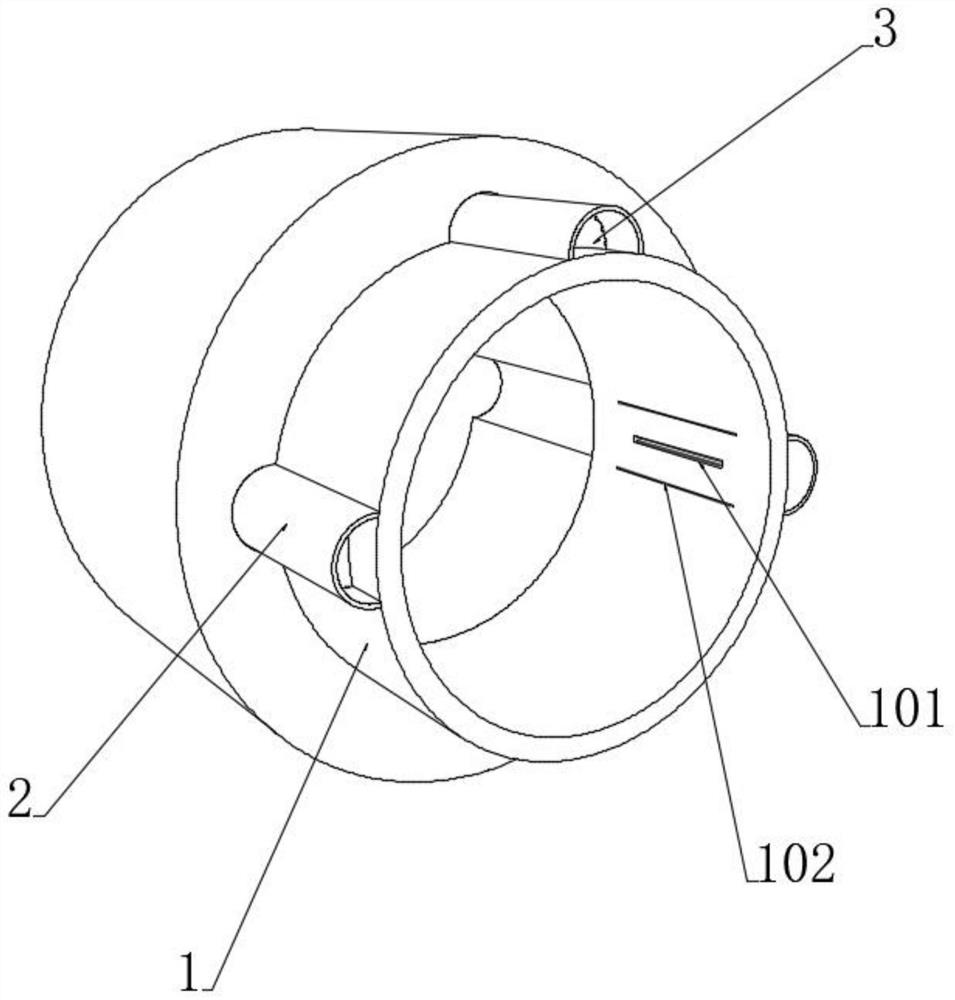

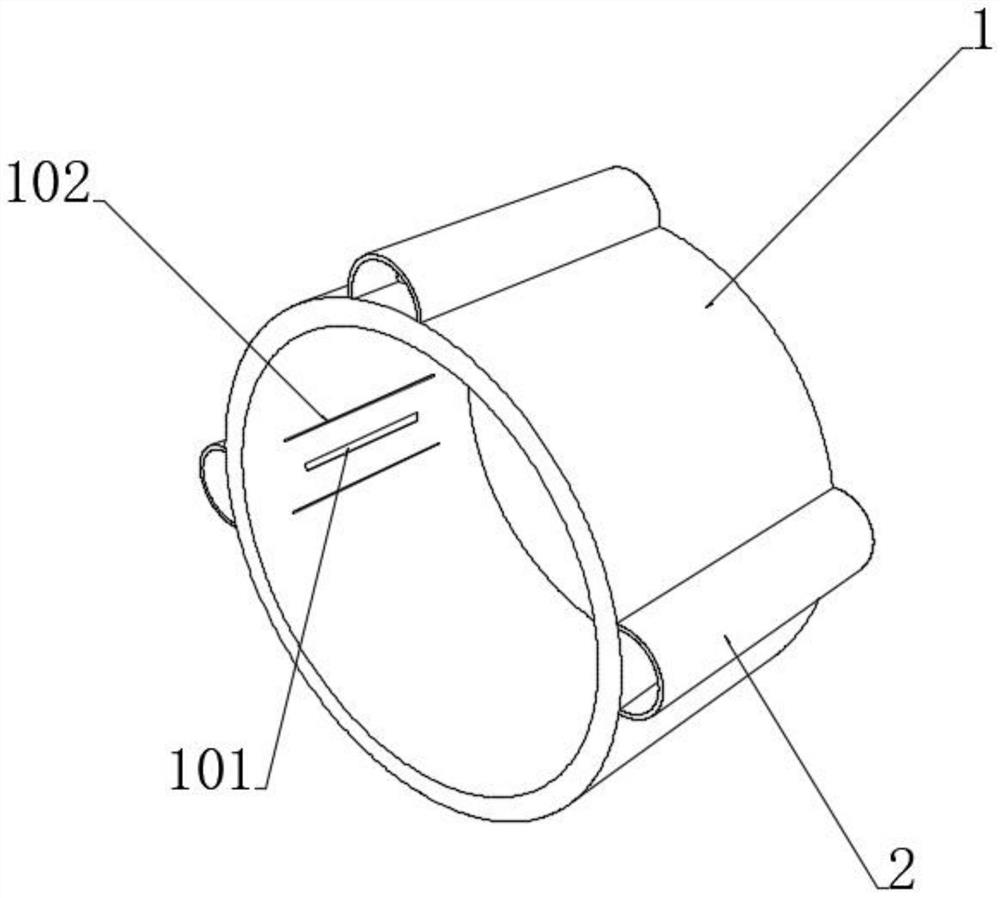

[0045] see Figure 1-3 and Figure 6-7 , a heat-induced self-lubricating bearing wear-resistant shaft sleeve, comprising a sleeve body 1, the sleeve body 1 is sleeved in the shaft sleeve hole, the top and both sides of the outer side wall of the sleeve body 1 are fixedly connected with an embedded sleeve 2, the shaft An embedding cavity corresponding to the position of the embedding sleeve 2 is opened in the sleeve hole, and an oil feed body is sleeved and installed in the interior of the plurality of embedded sleeves 2. The inner wall of the sleeve body 1 is provided with a corresponding position of the oil feed body. The oil outlet 101, the oil supply body includes a heat conduction sleeve 3 embedded in the inner side of the embedded sleeve 2, the inner middle of the heat conduction sleeve 3 is provided with an oil storage bag 4, and the upper and lower ends of the heat conduction sleeve 3 are filled with the upper and lower ends of the oil storage bag 4. The thermal expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com