A road paver pumping distributor

A material distributor and paver technology, applied in roads, roads, road repairs, etc., can solve the problems of slow material distribution, lateral segregation of road mixture, etc., and achieve the effects of easy cleaning, improved service life, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the embodiments shown in the accompanying drawings, but the present invention is not limited to the following embodiments.

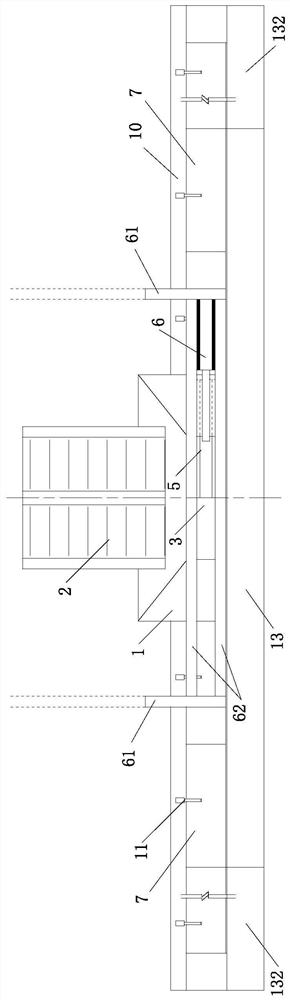

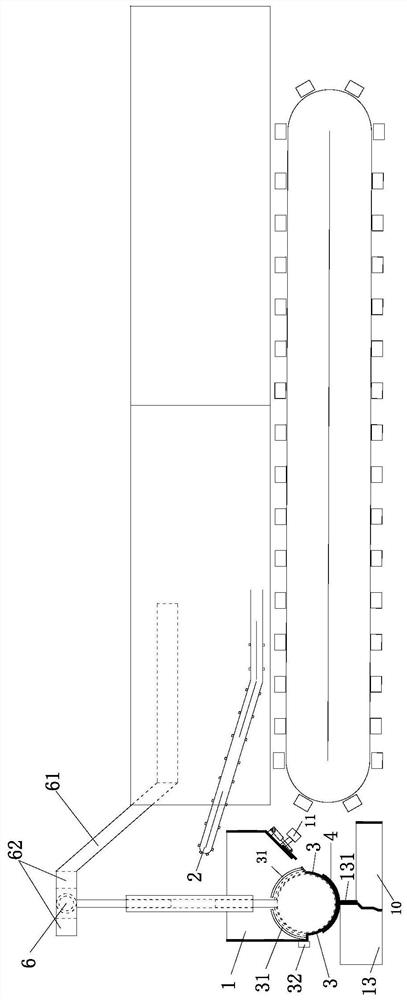

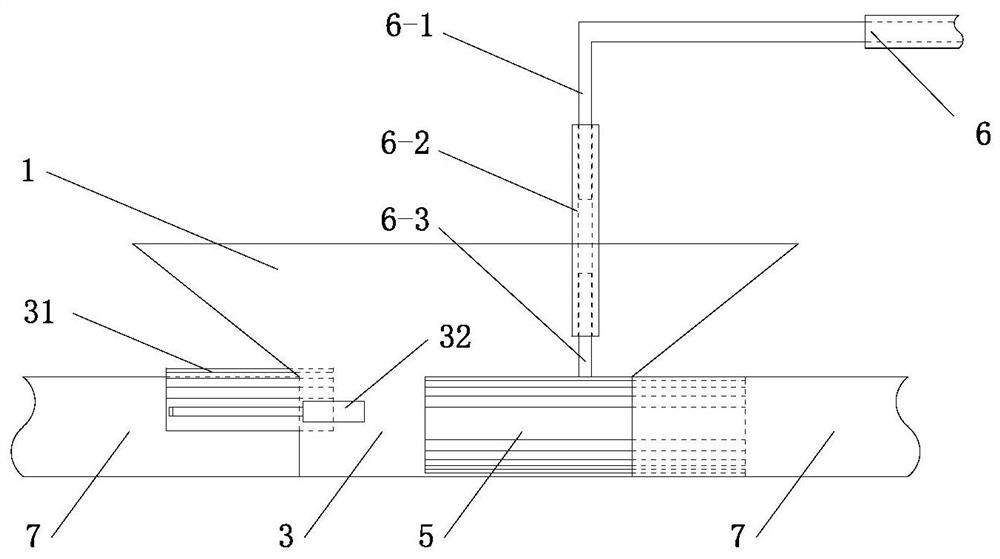

[0032] like figure 1 In the pumping distributor of the pavement paver shown, the rear hopper 1 is placed under the rear end of the scraper conveyor belt 2, and the pavement mixture conveyed by the scraper conveyor belt is loaded into the rear hopper. The width of the upper opening of the rear hopper should be greater than the width of the scraper conveyor belt, and the depth of the hopper should be greater than 400mm; the bottom of the rear hopper is connected to a horizontally arranged semi-circular steel pipe 3. The recommended inner diameter of the semi-circular steel pipe is 300mm, length 1000mm, and wall thickness 10mm. The semi-circular steel pipe is provided with a long groove extending along the busbar (on the cross-section of the semi-circular steel pipe, the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com