A mixing method for high-performance emulsified asphalt plant mixed cold recycled mixture

A technology for cold recycling mixture and asphalt mixture, which is applied in the field of cold mixing and recycling in asphalt plants, can solve the problems of occupying tense land resources, pollute the environment, environmental pollution, etc. Longevity and the effect of ensuring the quality of paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

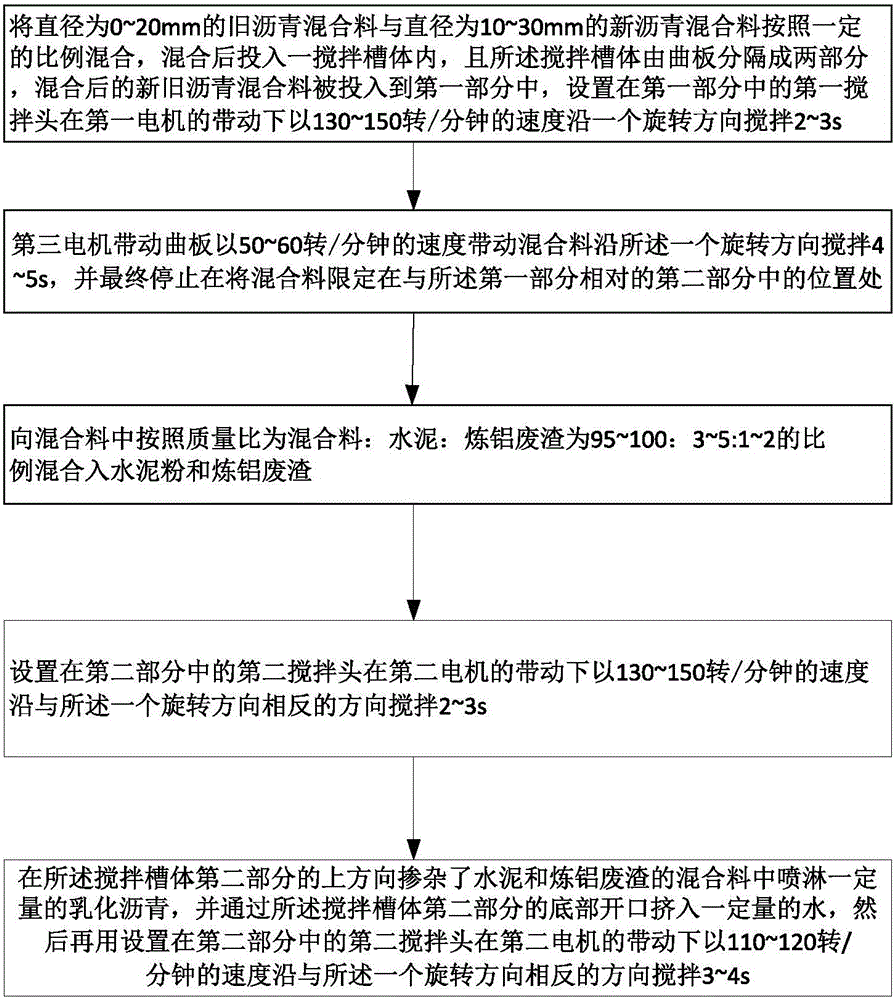

[0025] The invention provides a mixing method of high-performance emulsified asphalt plant mixed cold recycled mixture, comprising the following steps:

[0026] Step 1. Mix the old asphalt mixture with a diameter of 0-20mm and the new asphalt mixture with a diameter of 10-30mm according to the ratio of 75:15, and put them into a mixing tank after mixing. The mixing tank has an oval upper opening The tank body, and the stirring tank body is divided into two parts by a curved plate, the curved plate is two curved parts arranged in opposite directions, and a plurality of protrusions are arranged on each surface of the curved plate, and the length of the protruding protrusions is 1 / 15 of the long axis of the oval first mixing tank, the protrusions are triangular cone-shaped protrusions, and are evenly distributed on each side of the curved plate, the mixed new and old asphalt mixture is put into the first part, set in The first stirring head in the first part is driven by the firs...

Embodiment 2

[0032] The invention provides a mixing method of high-performance emulsified asphalt plant mixed cold recycled mixture, comprising the following steps:

[0033] Step 1. Mix the old asphalt mixture with a diameter of 0-20mm and the new asphalt mixture with a diameter of 10-30mm according to the ratio of 75:15, and put them into a mixing tank after mixing. The mixing tank has an oval upper opening The tank body, and the stirring tank body is divided into two parts by a curved plate. The curved plate is four curved parts arranged oppositely in pairs. Each surface of the curved plate is provided with a plurality of protrusions, and the protruding protrusions The length is 1 / 20 of the long axis of the first oval mixing tank, and the protrusions are triangular conical protrusions, which are evenly distributed on each surface of the curved plate, and the mixed old and new asphalt mixture is put into the first part, The first stirring head arranged in the first part is driven by the f...

Embodiment 3

[0039] The invention provides a mixing method of high-performance emulsified asphalt plant mixed cold recycled mixture, comprising the following steps:

[0040] Step 1. Mix the old asphalt mixture with a diameter of 0-20mm and the new asphalt mixture with a diameter of 10-30mm according to the ratio of 75:15, and put them into a mixing tank after mixing. The mixing tank has an oval upper opening The tank body, and the stirring tank body is divided into two parts by a curved plate. The curved plate is four curved parts arranged oppositely in pairs. Each surface of the curved plate is provided with a plurality of protrusions, and the protruding protrusions The length is 1 / 18 of the long axis of the oval first mixing tank, the protrusion is a mushroom-shaped protrusion, the diameter ratio of the mushroom head to the mushroom neck is 1.56:1, and the mixed old and new asphalt mixture is put into the first part , the first stirring head arranged in the first part is driven by the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com