Ruthenium atomic-scale loaded manganese oxide catalyst as well as preparation method and application thereof

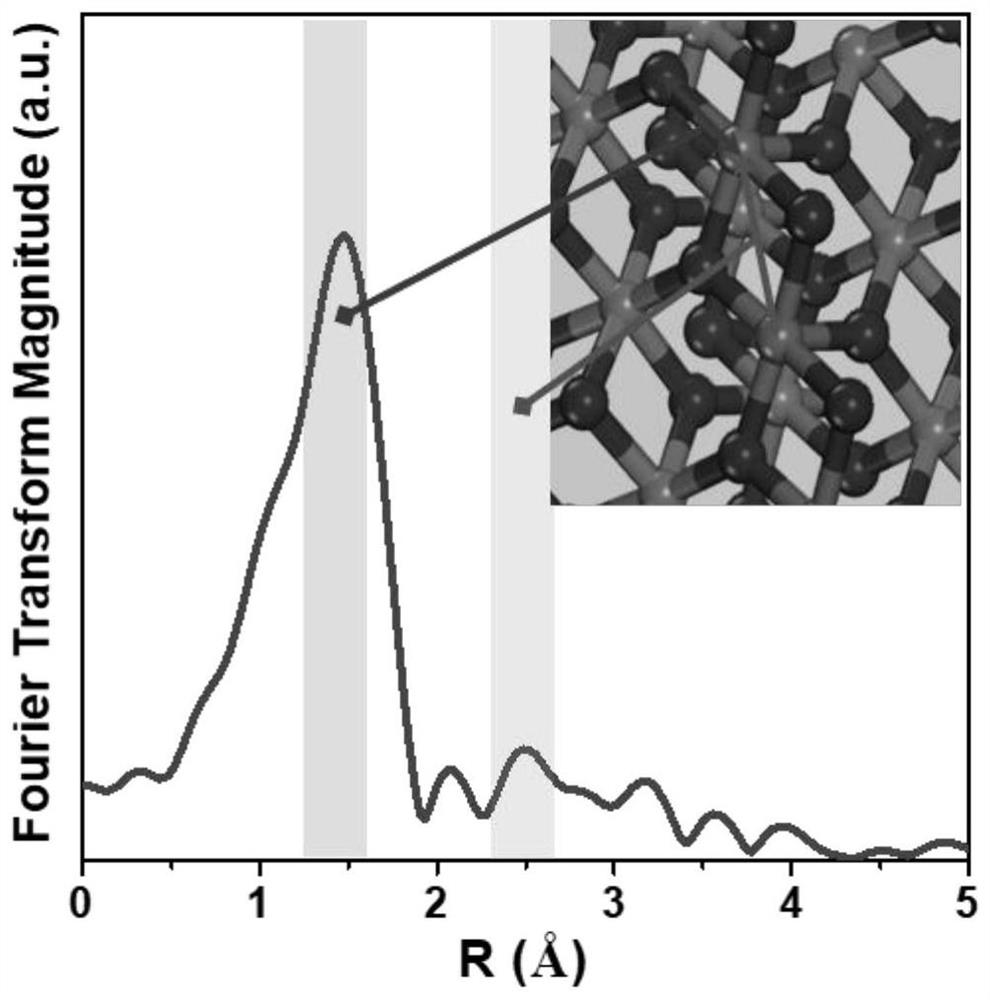

A catalyst and atomic-level technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of few types of acidic OER catalysts, low activity, poor stability, etc., to improve intrinsic activity and stability, improve dispersion effect, The effect of optimizing the charge distribution structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

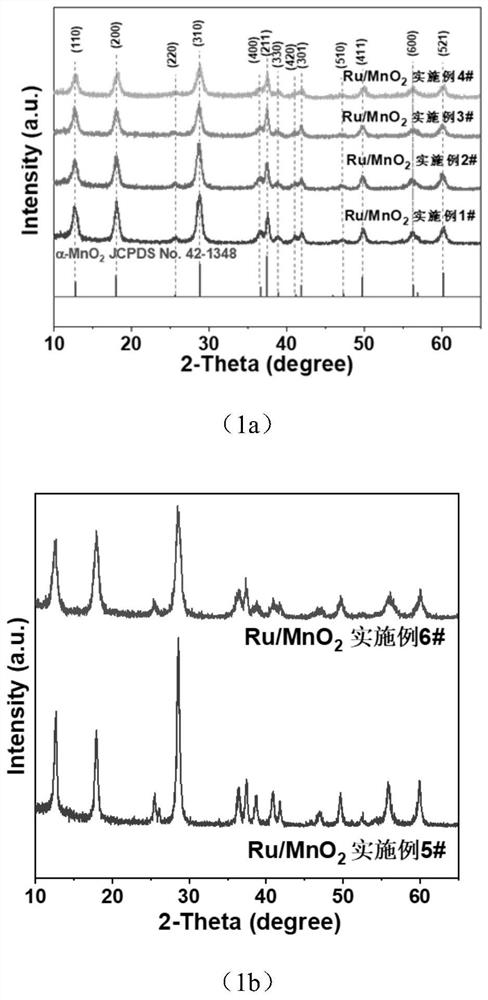

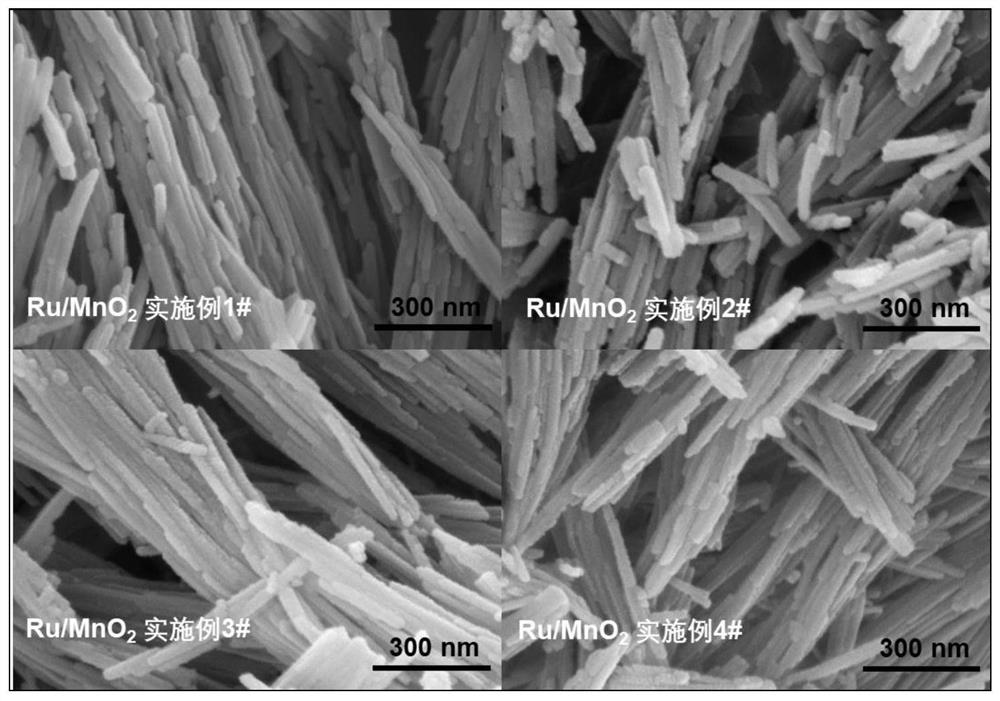

[0074] 0.02 mol of manganese sulfate, 0.06 mol of potassium sulfate, and complete dissolved were added after 70 mL of an aqueous concentration of 0.28 mol / L. The mixed solution was placed in a hydrothermal kettle, and the water was hot reaction at a temperature of 140 ° C, and the mixture was washed with deionized water, dried at 80 ° C for 12 h to obtain a solid product A.

[0075] A 15 mmol solid product A ultrasound was dispersed in 20 ml of deionized water, and 20 mL of a concentration of 2.41 mol / L was added. 3 After stirring the reaction for 1 h, filtration is completely dried, and a large amount of deionized water is filtered, 12 h is dried at 80 ° C, and the temperature is calcined in the air atmosphere for 1 h, naturally cooled to room temperature. RU / MNO 2 Catalyst sample 1 #.

Embodiment 2

[0077] 0.014 mol of manganese nitrate, 0.043 mol of potassium nitrate was added, and the mixture was completely dissolved in a 50 mL concentration of 0.28 mol / L. The mixed solution was placed in a hydrothermal kettle, and the water was hot reaction at a temperature of 140 ° C, and the mixture was washed with deionized water, dried at 80 ° C for 12 h to obtain a solid product A.

[0078] A 15 mmol solid product A ultrasound was dispersed in 20 ml of deionized water, and 20 mL of a concentration of 4.82 mol / L was added at one time. 3 After 1 h, the reaction was stirred for 1 h, and the filtration was filtered to the solid precipitate, washed with a large amount of deionized water, dried at 80 ° C for 8 h, and calcined in the air atmosphere at 200 ° C for 1 h, naturally cooled to room temperature RU / MNO 2 Catalyst sample 2 #.

Embodiment 3

[0080] 0.028 mol of manganese nitrate, 0.086 mol of potassium nitrate was added, and the mixture was completely dissolved in an aqueous ammonium ammonium sulfate solution of 0.28 mol / L. The mixed solution was placed in a hydrothermal kettle, and the water was hot reaction at a temperature of 140 ° C, and the mixture was washed with deionized water, dried at 80 ° C for 12 h to obtain a solid product A.

[0081] 15 mmol solid product A ultrasound was dispersed in 20 ml deionized water, and 20 ml of concentration of 9.64 mol / L was added. 3 After 1 h, the aqueous solution was stirred for 1 h, and the solid precipitate was filtered to be completely dried, and the mixture was washed with a large amount of deionized water, dried at 70 ° C for 12 h, and calcined in the air atmosphere in the air atmosphere for 1 h, naturally cooled to room temperature RU / MNO 2 Catalyst sample 3 #.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com