Combined extraction method of complex copper and cobalt raw materials

A combined extraction and copper-cobalt technology, applied in the field of metallurgical mines, can solve the problems of low metal leaching rate, metal loss, increased engineering investment, etc., and achieve the effects of low metal loss rate, reduction of metal amount, and improvement of comprehensive utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

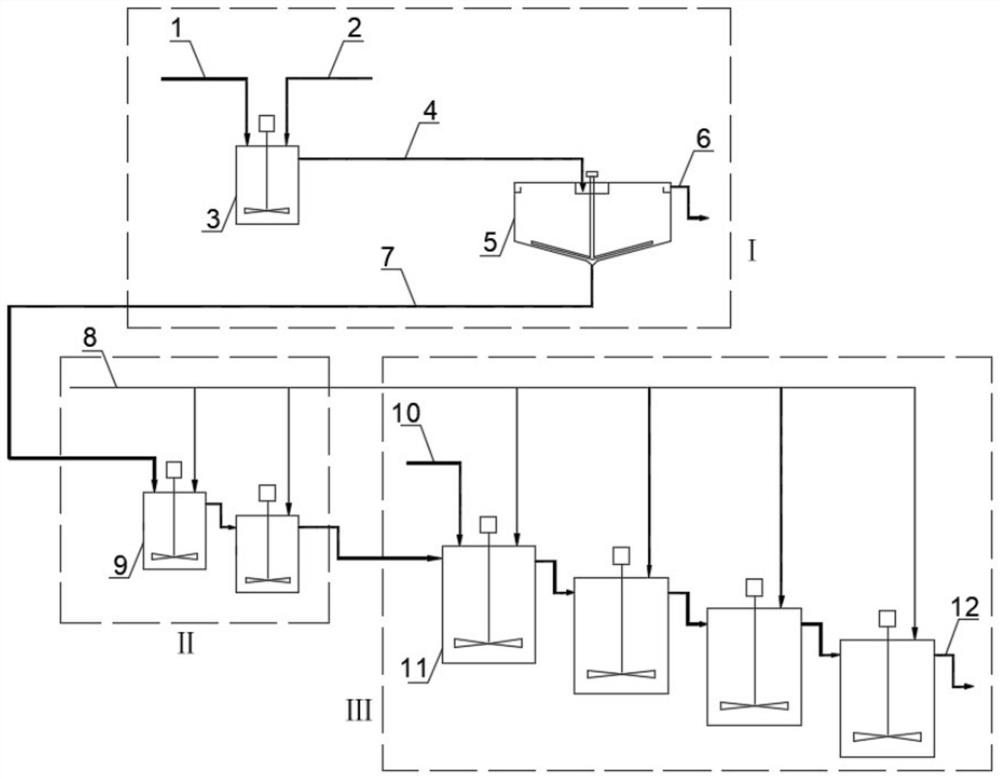

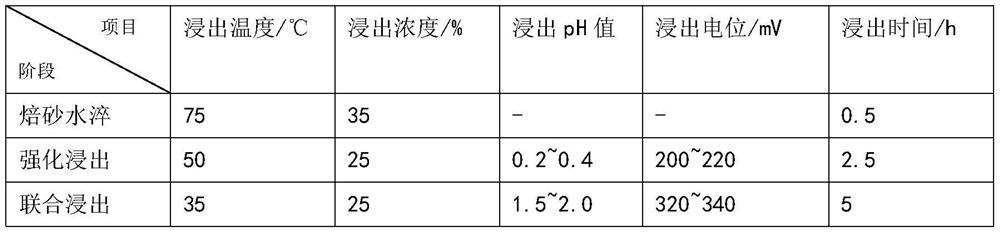

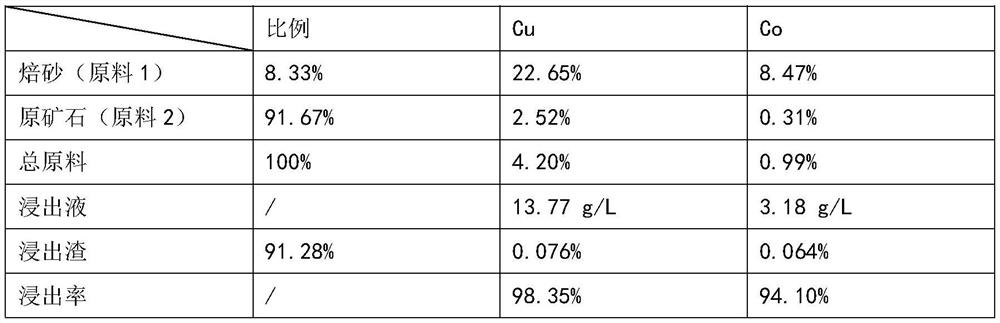

[0029] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] In the prior art, raw materials with different forms of the same metal are usually extracted by different production lines, which greatly increases the project investment, or even if the same production line is used, there are problems such as low metal leaching rate and serious metal loss. The invention develops a combined extraction method of composite raw materials with different forms and different grades, which enables the joint extraction of raw materials of the same metal with different forms to share the same production line, which greatly simplifies the production process and has the advantages of high leaching rate and low metal loss rate.

[0031] In the following expressions, the high-grade raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com